Construction method for treating soft soil foundation by solidifying agent

A technology of soft soil foundation and construction method, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as the decline of curing effect, and achieve the effect of high construction efficiency, high strength and good water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

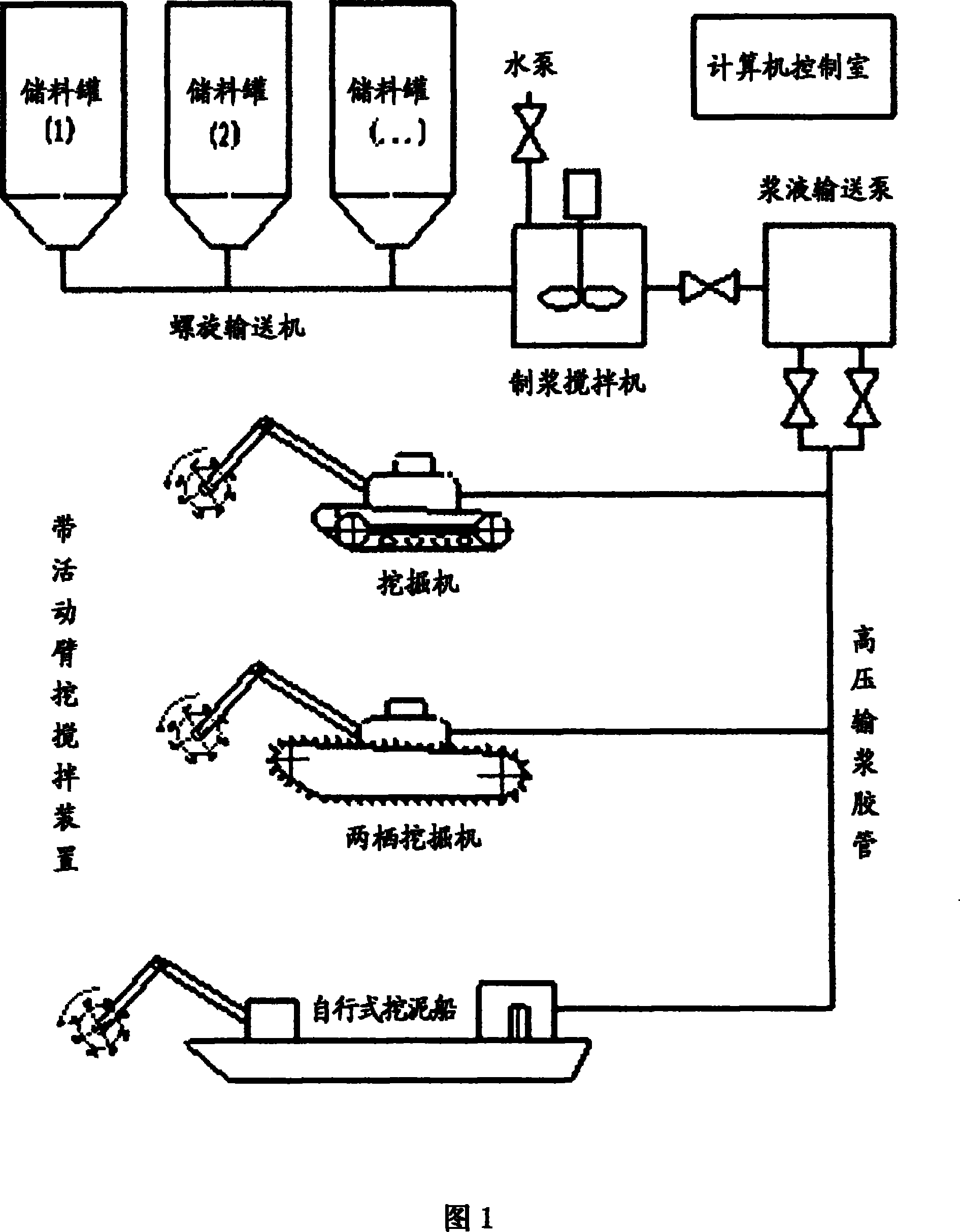

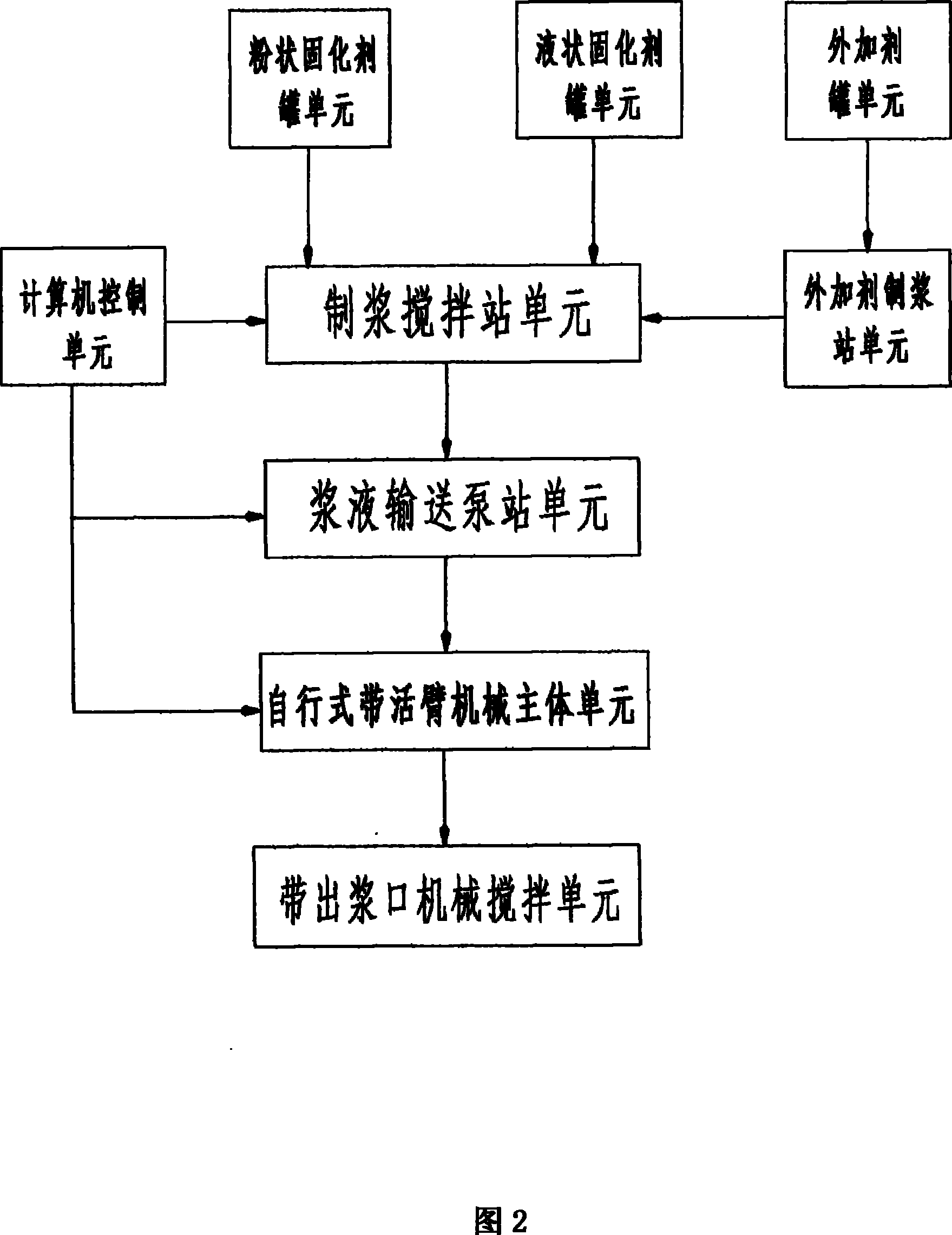

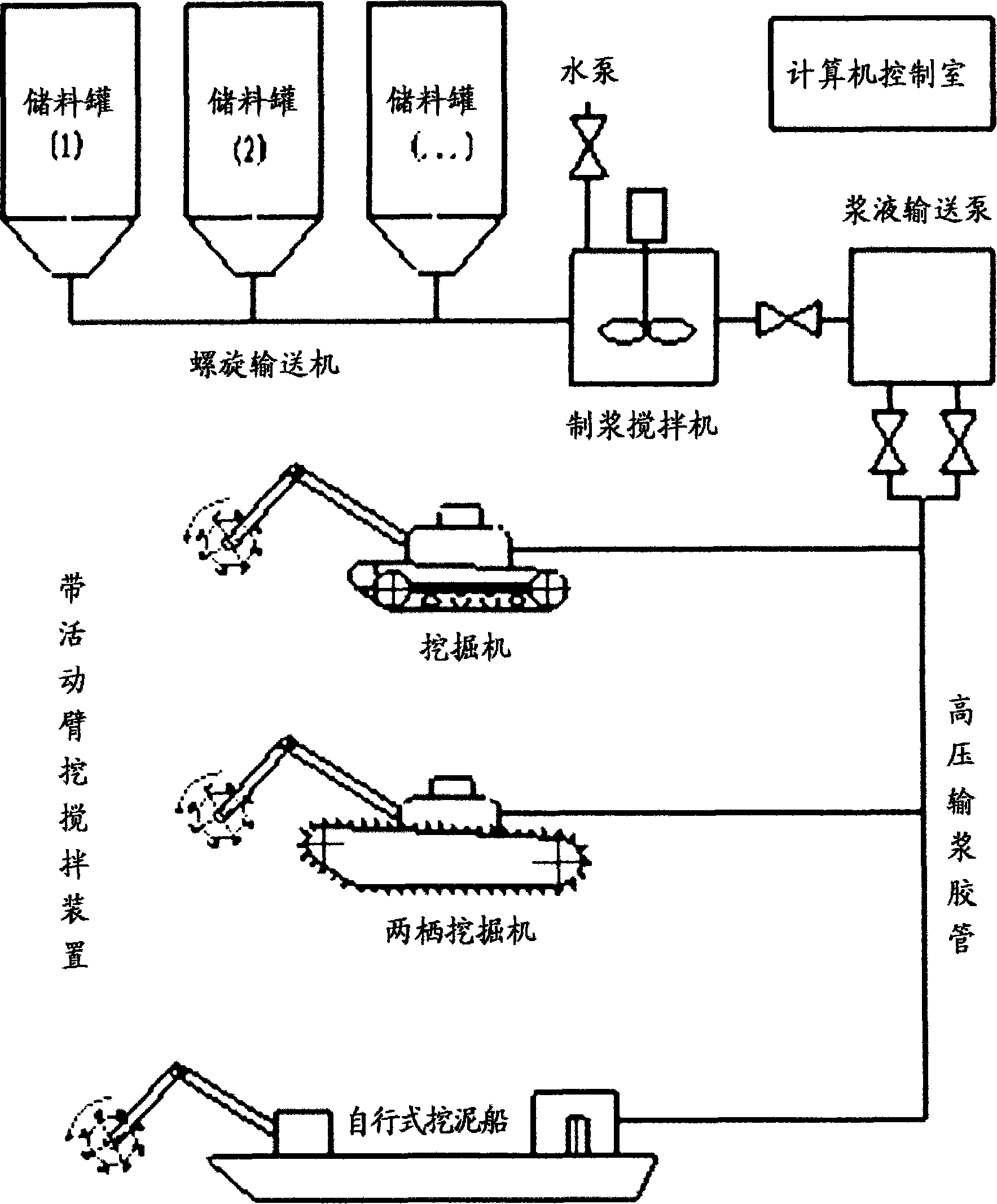

Method used

Image

Examples

Embodiment 1

[0036] Tangshan Caofeidian Steel Factory North Road Section 2, the subgrade is silty sand, silty fine sand contains about 9% silty clay particles, silty fine sand contains about 30% saturated water, the surrounding environment makes the subgrade drainage difficult, and local subgrade surface water, The average daily temperature during construction is about 10 degrees Celsius. The imported excavator is equipped with an imported mixing head device, and a domestic slurry supply system is adopted. The slurry water-cement ratio is 0.5, the curing agent slurry delivery distance is more than 300 meters, and the design requires a consolidation depth of 0.8 meters. Add 7% powder, 3.5% water, and 0.07% commercially available concrete retarder to the silty fine sand consolidation body by weight percentage. The powder is composed of 70 parts of slag, 20 parts of fly ash, 5 parts of gypsum, 3 parts of anhydrous sodium sulfate, and 2 parts of sodium carbonate. The speed of mixing construct...

Embodiment 2

[0038] At the zero kilometer of Caofeidian North Ring Road in Tangshan, the subgrade is shallow beach silt, the thickness of the silt layer is about 1.5 meters, the moisture content of the silt is about 90%, and the surface bearing capacity of the original silt is less than 0.01Mpa. This area belongs to the intertidal zone, and the sea is deep when the tide is high. 30 cm, exposed to the water surface at low tide, the average daily temperature of the environment during construction is about 12 degrees Celsius; the imported excavator is equipped with a domestic mixing head device, and a domestic slurry supply system is adopted. The slurry water-cement ratio is 0.45, and the curing agent slurry delivery distance is 80 m; the depth of silt consolidation is 1.5 m. The powder is cement, and 4% of powder, 1.8% of water, 0.3% of liquid, and 0.03% of commercially available concrete retarder are added to the silt consolidated body by weight percentage. Wherein the liquid preparation is...

Embodiment 3

[0040] Tangshan Caofeidian Steel Factory North Road, the subgrade is silty sand, the silt fine sand contains about 18% silt clay, and the silt fine sand contains about 30% saturated water, and the local road is covered with water, and the daily average temperature during construction is about 10 degrees Celsius. Imported excavator is equipped with imported mixing head device, domestic pulping slurry supply system, slurry water-cement ratio is 0.5, curing agent slurry delivery distance is 200 meters, and the design consolidation depth is 0.8 meters. Percentage Add 7% powder, 3.5% water, 0.07% commercial concrete retarder. The powder is composed of the following components: 60 parts of slag, 33 parts of cement, 3 parts of gypsum, 2 parts of anhydrous sodium sulfate, and 2 parts of sodium carbonate. The construction speed is 80 cubic meters per hour. After mixing and construction, 30 cm of mountain soil is spread within 8 hours, and bulldozers are used to flatten and roll it. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com