Preparation method of anti-oxidizing agent

A technology of antioxidants and solvents, which is applied in the field of antioxidant preparation, can solve the problems of difficulty in industrialization implementation, high requirements for production equipment, and reduced quality of raw materials, and achieve the effects of saving raw material consumption, simple and easy process, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

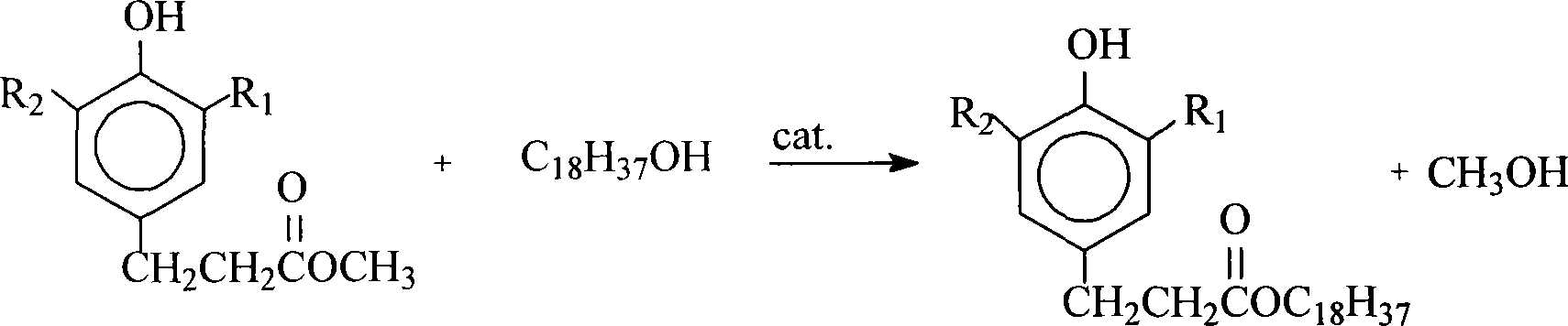

Method used

Image

Examples

Embodiment 1

[0014] Add 50ml of xylene to a 250ml four-necked flask equipped with a stirrer, a thermometer, a nitrogen conduit, a water separator and a condenser, start stirring, add 27.0g (0.10mol) of n-stearyl alcohol, 3-(3,5- 33.4g (0.12mol) of di-tert-butyl-4-hydroxyphenyl)propionic acid, 0.2g (0.001mol) of monobutylstannoic acid, feed nitrogen gas, heat up to reflux, keep the temperature of the reaction solution at about 160°C, and reflux for dehydration About 4.0 hours, the dehydration is close to the theoretical value. Cool down to 100°C, add 1.0g of activated carbon, keep stirring at 120-130°C for 30 minutes, cool down to 80-100°C, and filter. Recover xylene from the reaction solution at 180°C under normal pressure and reduced pressure (20-50mmHg), cool down to 60°C, add 150ml of isopropanol, crystallize at 25°C, filter through a Buchner funnel, rinse with isopropanol, and Dry to obtain 3-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 46.0g, melting point 50-53°C, puri...

Embodiment 2

[0016] Repeat the technique and condition of embodiment 1, xylene is replaced by toluene, and the consumption of toluene is 35ml, and decolorizing agent changes gac into activated clay. Obtain 45.4g of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propanoate, melting point 50-53°C, purity 98.8%, yield 85.85% (calculated by n-octadecanol ). 8.9 g of 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid was obtained. The final yield was 97.20% [based on 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid].

Embodiment 3

[0018] Repeat the process and conditions of Example 1, replacing isopropanol with ethanol, 0.4 g of monobutyl stannoic acid. Obtain 47.4 g of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propanoic acid n-stearyl alcohol ester, melting point 50-53° C., purity 98.3%, yield 89.43% (calculated by n-stearyl alcohol ). 8.2 g of 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid was obtained. The final yield was 98.66% [based on 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid].

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com