Cu doped MgB2 superconductor and low-temperature rapid preparation method

A superconductor and low-temperature technology, applied in the field of superconductivity, can solve problems such as slow diffusion rate, long sintering time, and increased cost of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The raw materials were thoroughly mixed in an agate mortar according to the above ratio, and then pressed into thin slices under a pressure of 5 MPa. Put the pressed sample into a high-temperature differential scanning calorimeter (NETZSCH DSC 404C Peganus) and pass through argon gas for low-temperature sintering. Sinter at this temperature for 5 hours, and then cool down to room temperature at a cooling rate of 20°C / min.

Embodiment 2

[0021] Mix the raw materials thoroughly in an agate mortar according to the above proportions, and then press them into flakes under a pressure of 2 MPa. Put the pressed sample into a high-temperature differential scanning calorimeter (NETZSCH DSC 404C Peganus) and pass through argon gas for low-temperature sintering. Sinter at this temperature for 10 hours, and then cool down to room temperature at a cooling rate of 10°C / min.

Embodiment 3

[0023] The raw materials were thoroughly mixed in an agate mortar according to the above ratio, and then pressed into flakes under a pressure of 10 MPa. Put the pressed sample into a tube-type sintering furnace and pass in argon gas for low-temperature sintering. The set program is: the heating rate is 40°C / min, and after rising to 600°C, it is kept at this temperature for 2 hours. Then cool down to room temperature at a cooling rate of 40°C / min.

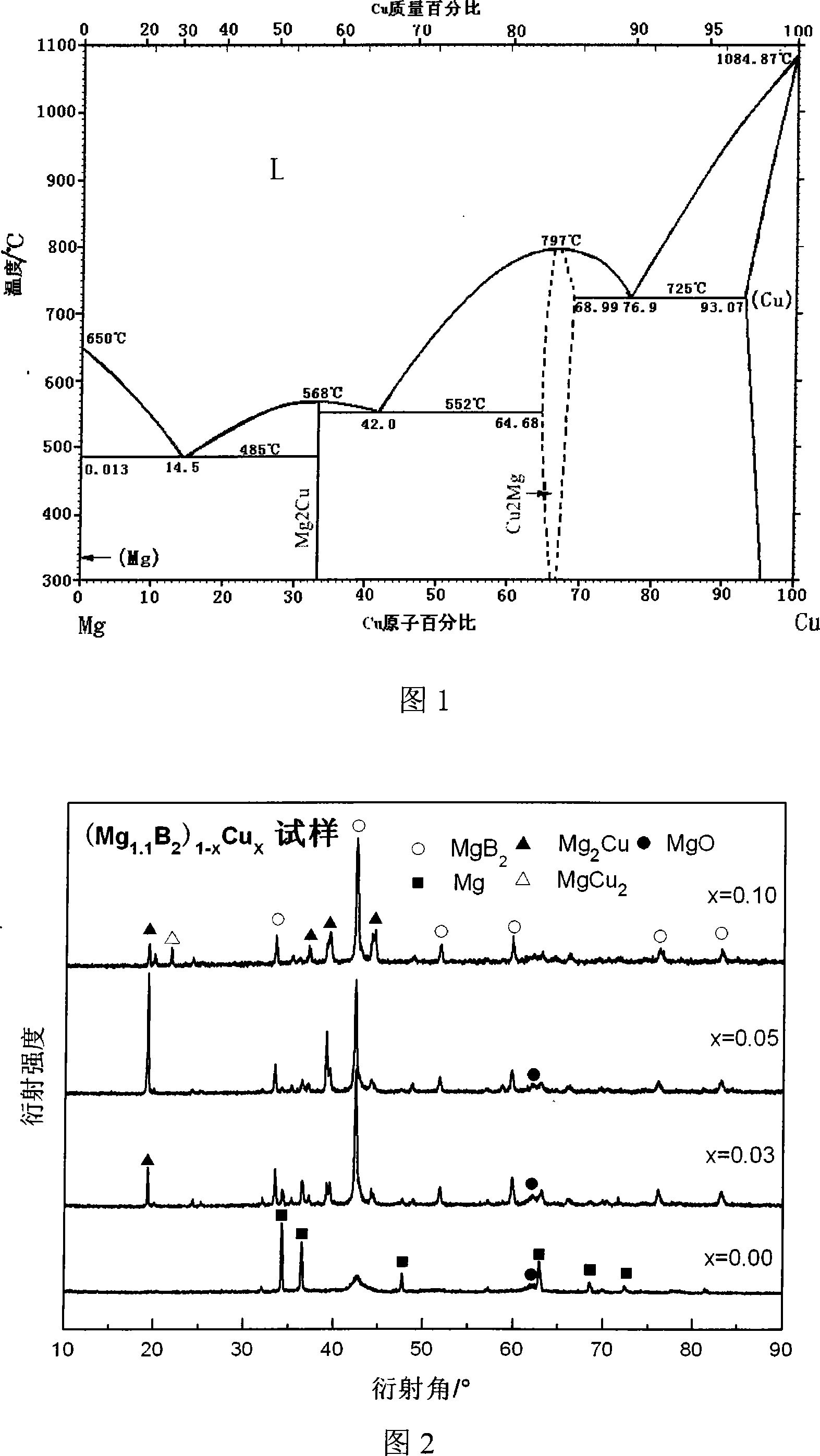

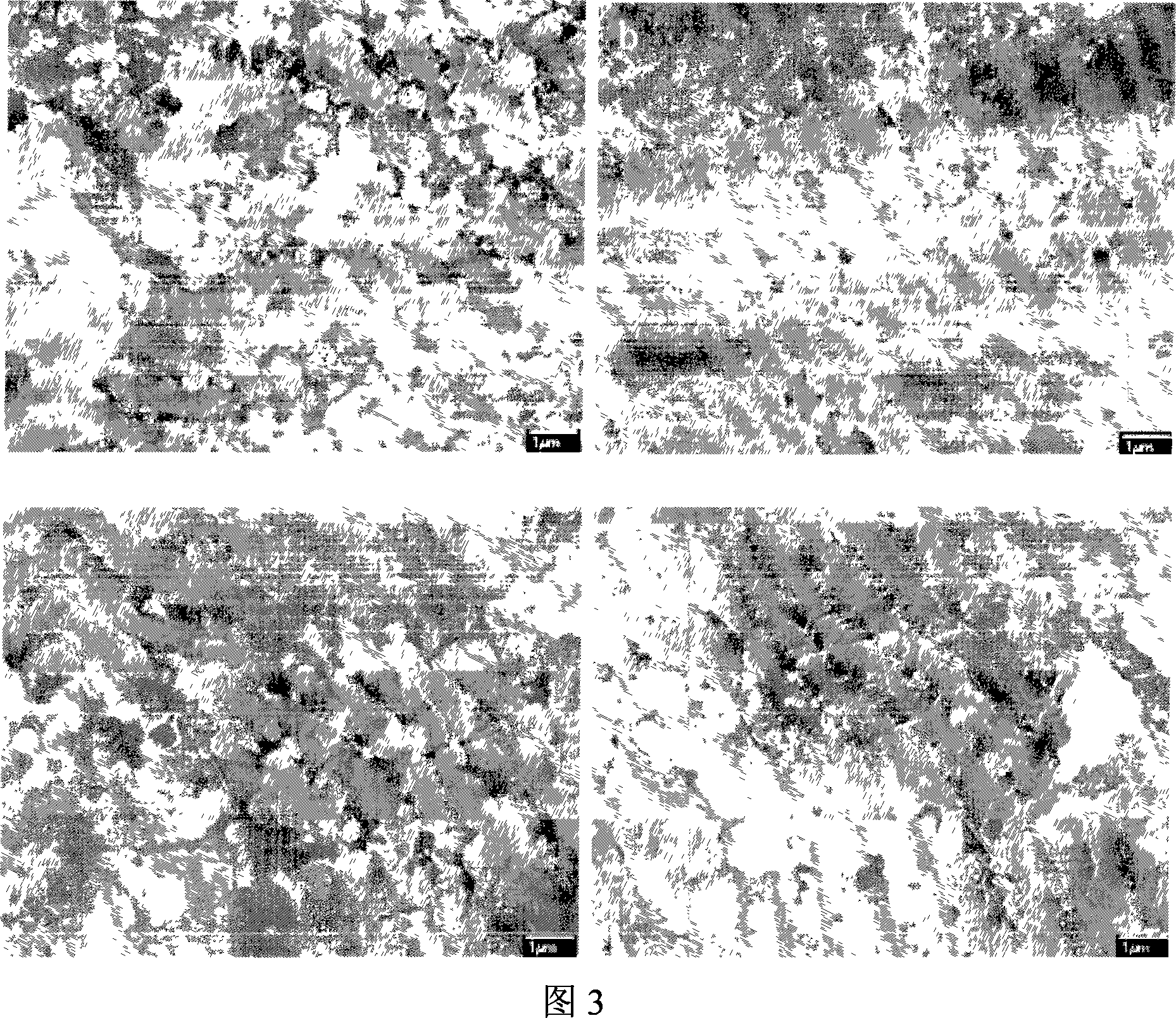

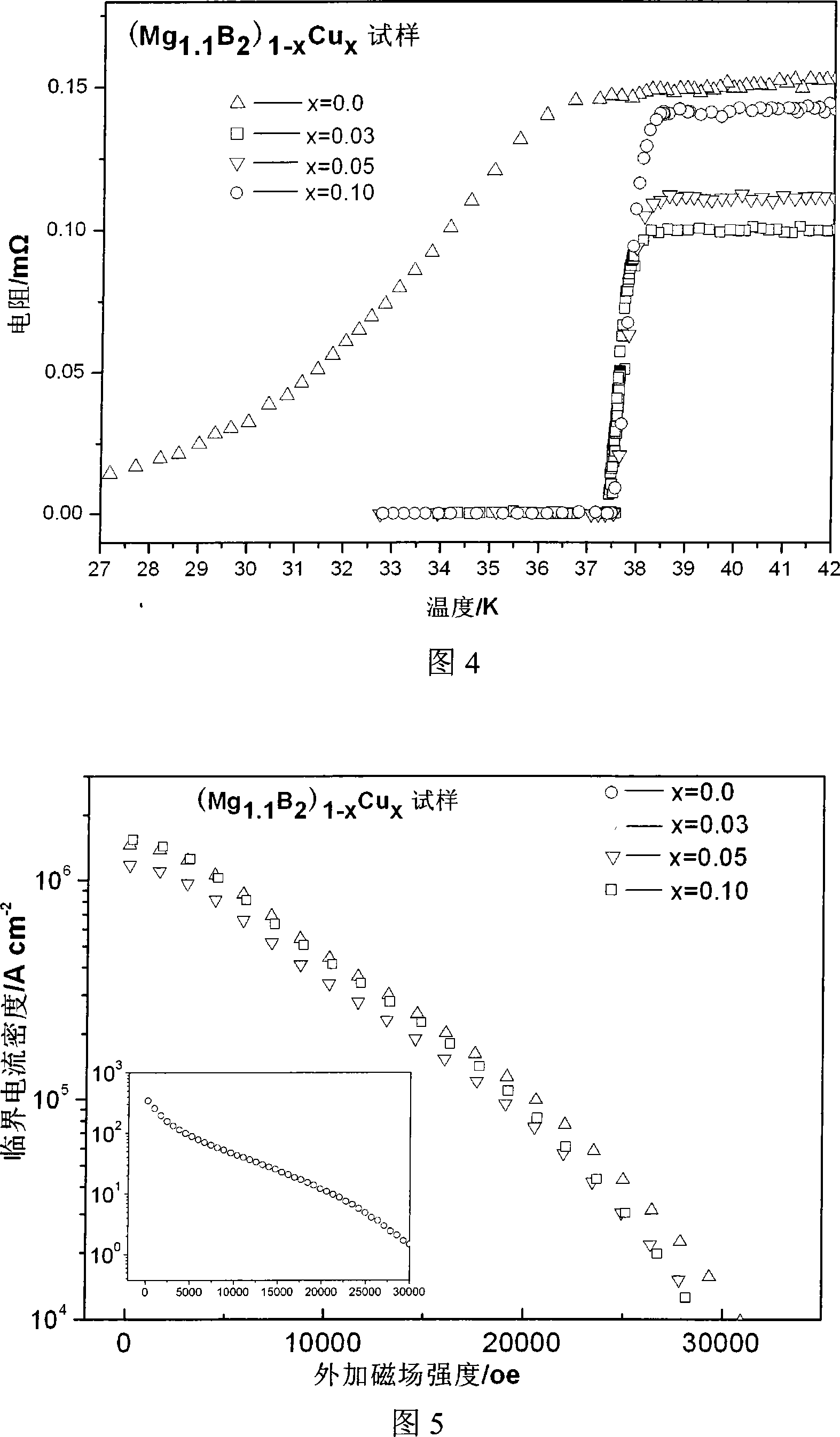

[0024] A small amount of Cu is selected as dopant, and MgB is prepared by powder sintering method 2 Superconductors can not only reduce the reaction temperature, but also greatly shorten the sintering time. Figure 2 shows the X-ray diffraction patterns of samples with different ratios after sintering. It can be seen from the figure that in the sample without Cu doping, Mg is still the main phase, but in the sample only doped with 3% Cu, MgB 2 Phase has become the main phase. Figure 3 shows the (Mg 1.1 B 2 ) 1-x Cu x Scanning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com