Inverted type machine tool

An inverted, machine tool technology, applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the difficulty of machine tool transportation, movement and installation, increase transportation costs, increase machine tool material costs and processing Cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

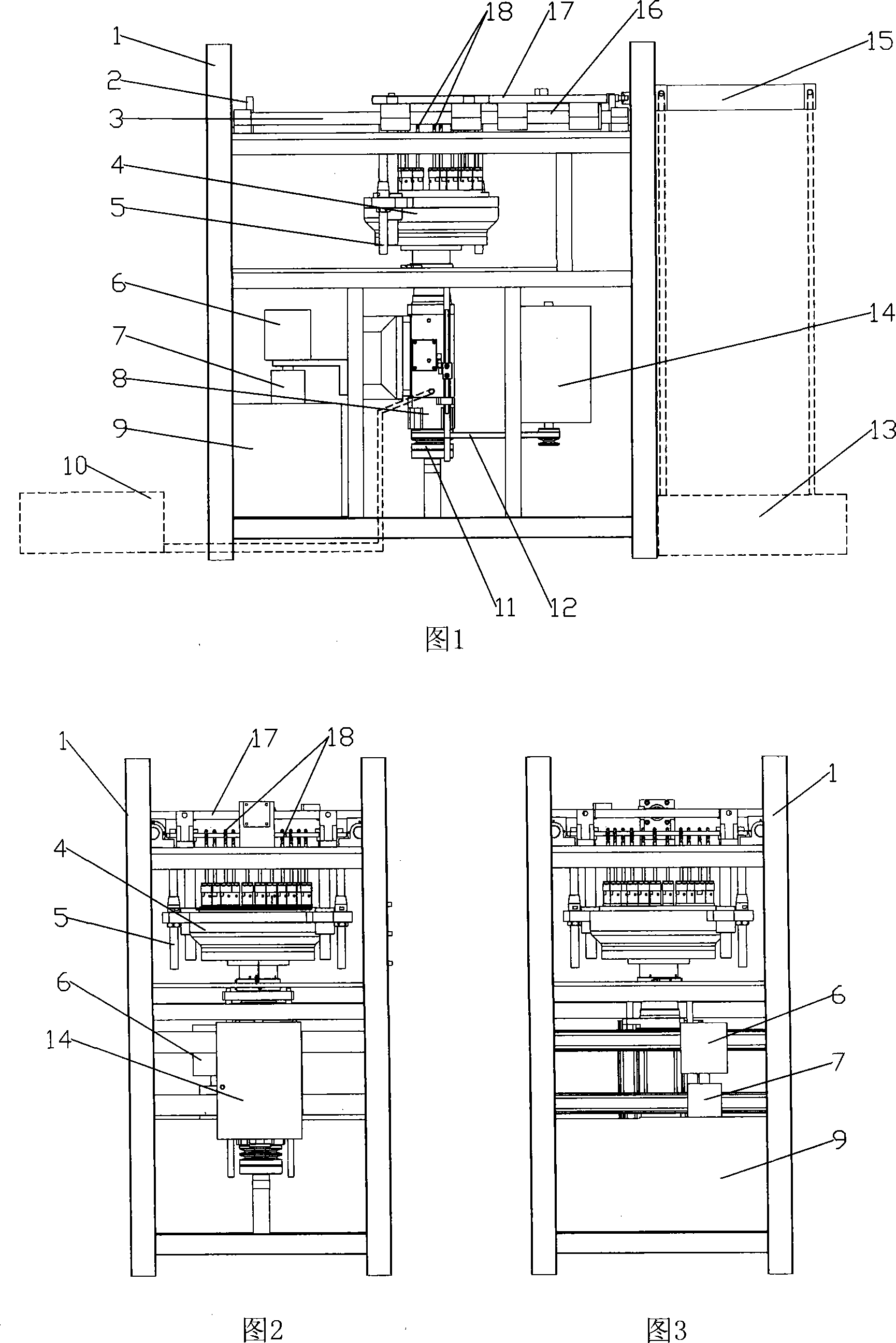

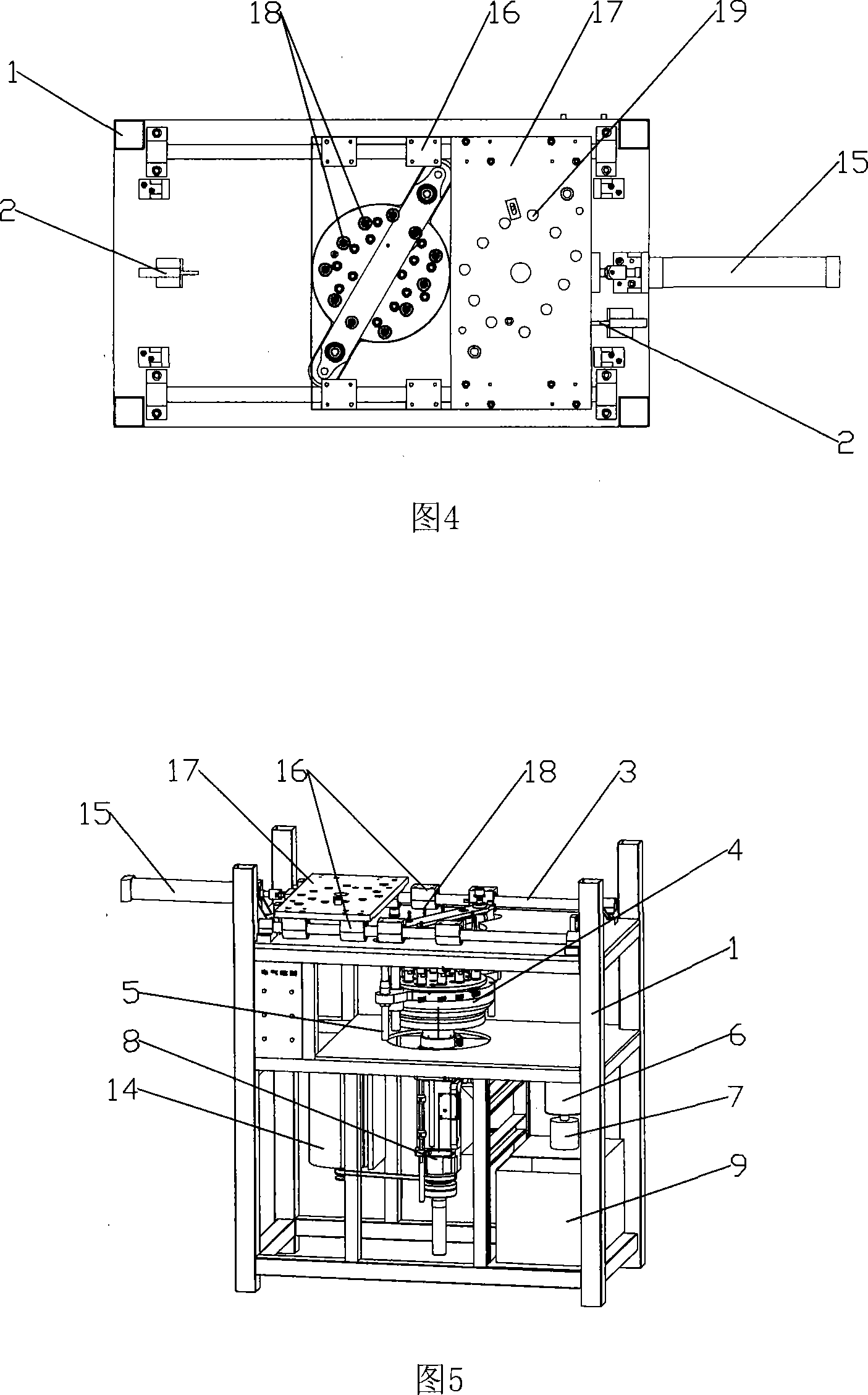

[0013] The inverted machine tool of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

[0014] As shown in Fig. 1 to Fig. 5, it is a kind of inverted multi-head drilling machine, including a three-dimensional frame frame 1, which is installed on the In the frame 1, a plurality of drill bits 18 are installed on the output end of the power head 8 through the multi-axis device 4 in an upward manner to form an upward feeding processing method, and the tooling fixture formed by the tooling plate 17 for fixing the workpiece is installed on the Frame 1 top is positioned at the position above drill bit, and the position of corresponding drill bit is provided with borehole 19 and the hole that workpiece is fixed on the tooling plate 17, can be equipped with drill sleeve to prevent the swing of drill bit in the machining process in borehole 19.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com