Coal seam wind and spray linked coal core drilling tools and its method for coal core drilling

A coal seam wind and water mist technology, which is used in earth-moving drilling, extraction of undisturbed core devices, etc., can solve the problems of coal core burnout, gas disaster, insufficient cooling of the drill bit, etc., and achieves good cooling and overcomes the effect of insufficient cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

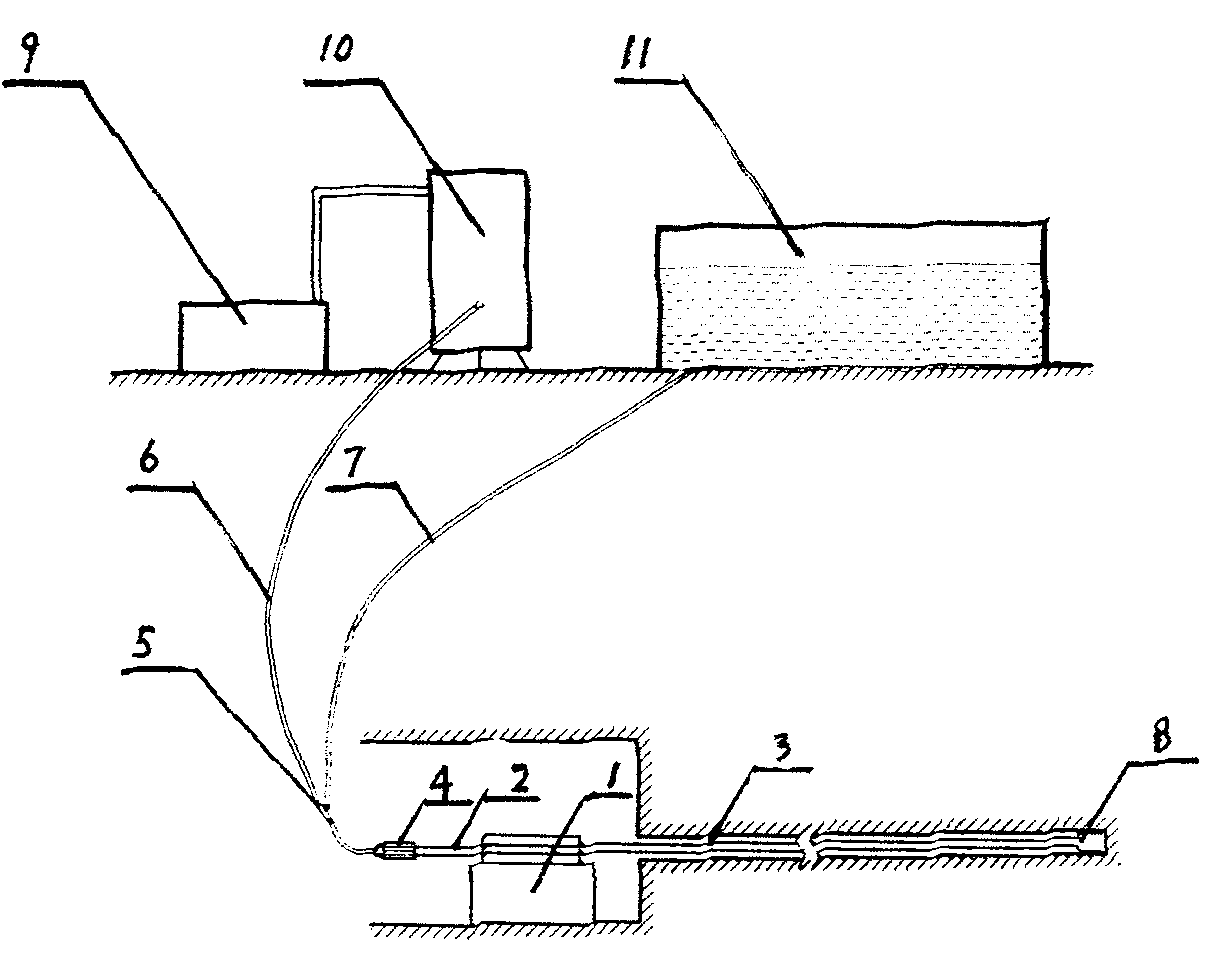

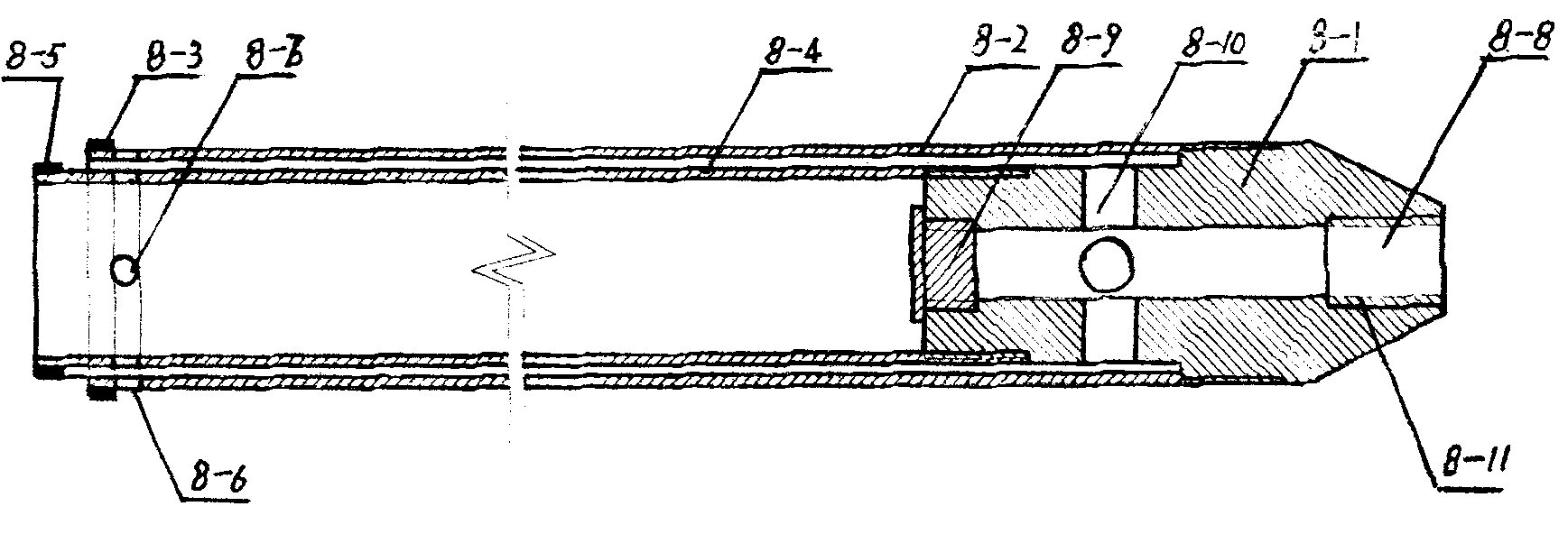

[0057] The coal seam air and water mist linkage drilling tool for coal core described in the present invention is composed of an existing pneumatic drilling machine, a developed water atomization device and a coring pipe.

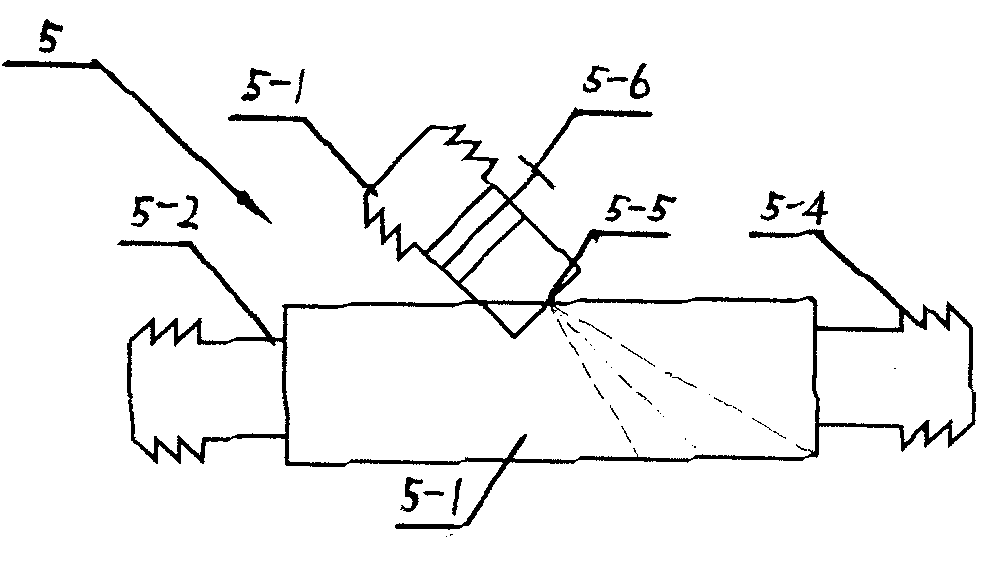

[0058] Connect the compressed air pipe connector 5-2 to one end of the atomization chamber 5-1, the front end is provided with a nozzle 5-5, and the water supply pipe connector with a water flow control valve 5-6 in the middle is connected to the middle part of the atomization chamber. The water mist outlet joint 5-4 is connected to the other end of the atomization chamber, which constitutes the water atomization device 5 of the coal seam wind and water mist linkage drilling coal core tool; the pressure air pipe joint 5-2 of the water atomization device passes through the pipeline It is connected with the air bag 10 of the underground or surface air compressor 9, and the air compressor provides the compressed air with a pressure of about 0.3-0.6MPa, forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com