Device for controlling double-acting air cylinder piston traveling speed

A double-acting cylinder, moving speed technology, applied in the direction of fluid pressure actuators, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of increasing wafer 1 cycle, reducing production efficiency, wafer 1 cracking, etc., achieving time and The effects of shortening the cycle, improving work efficiency, and speeding up the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

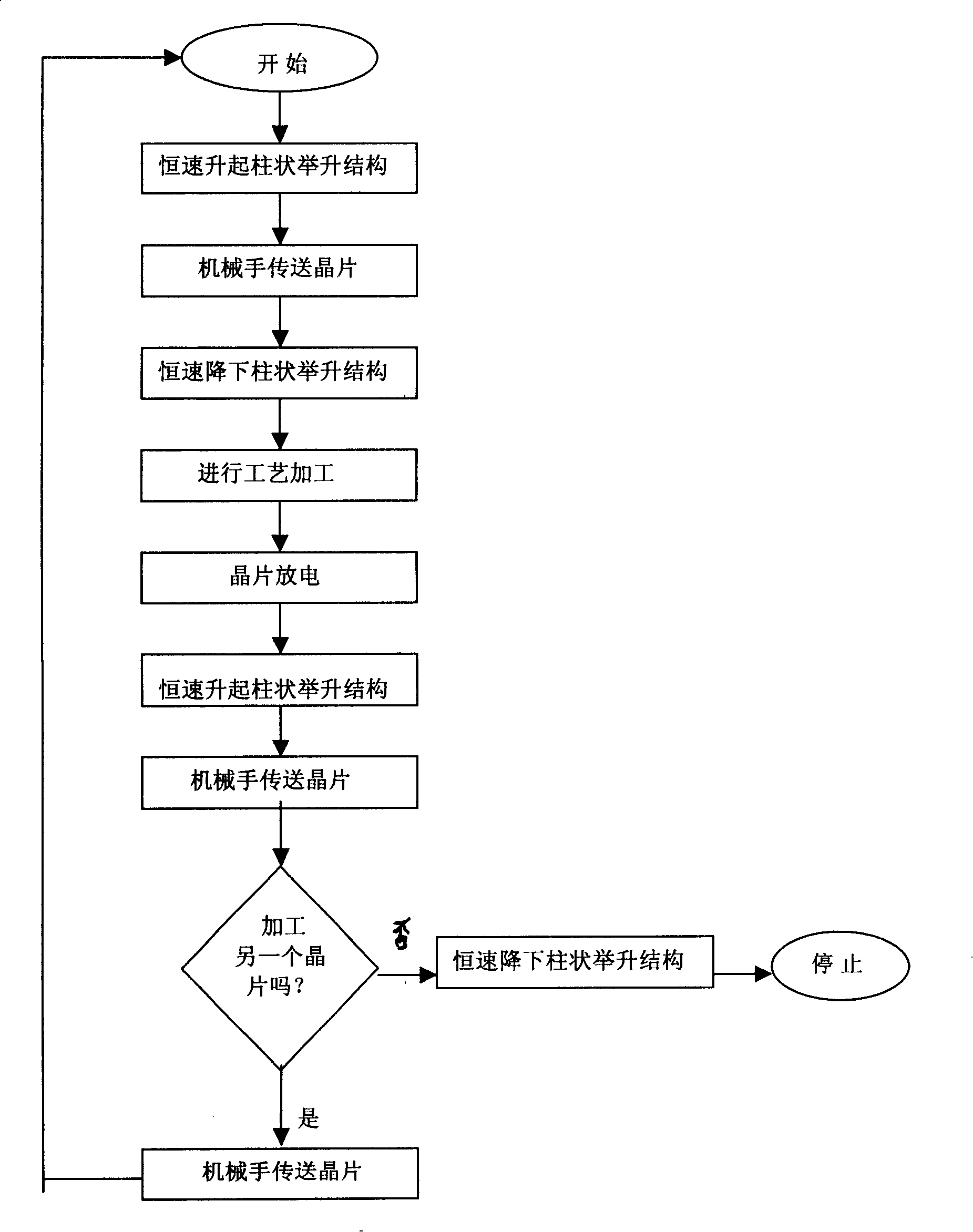

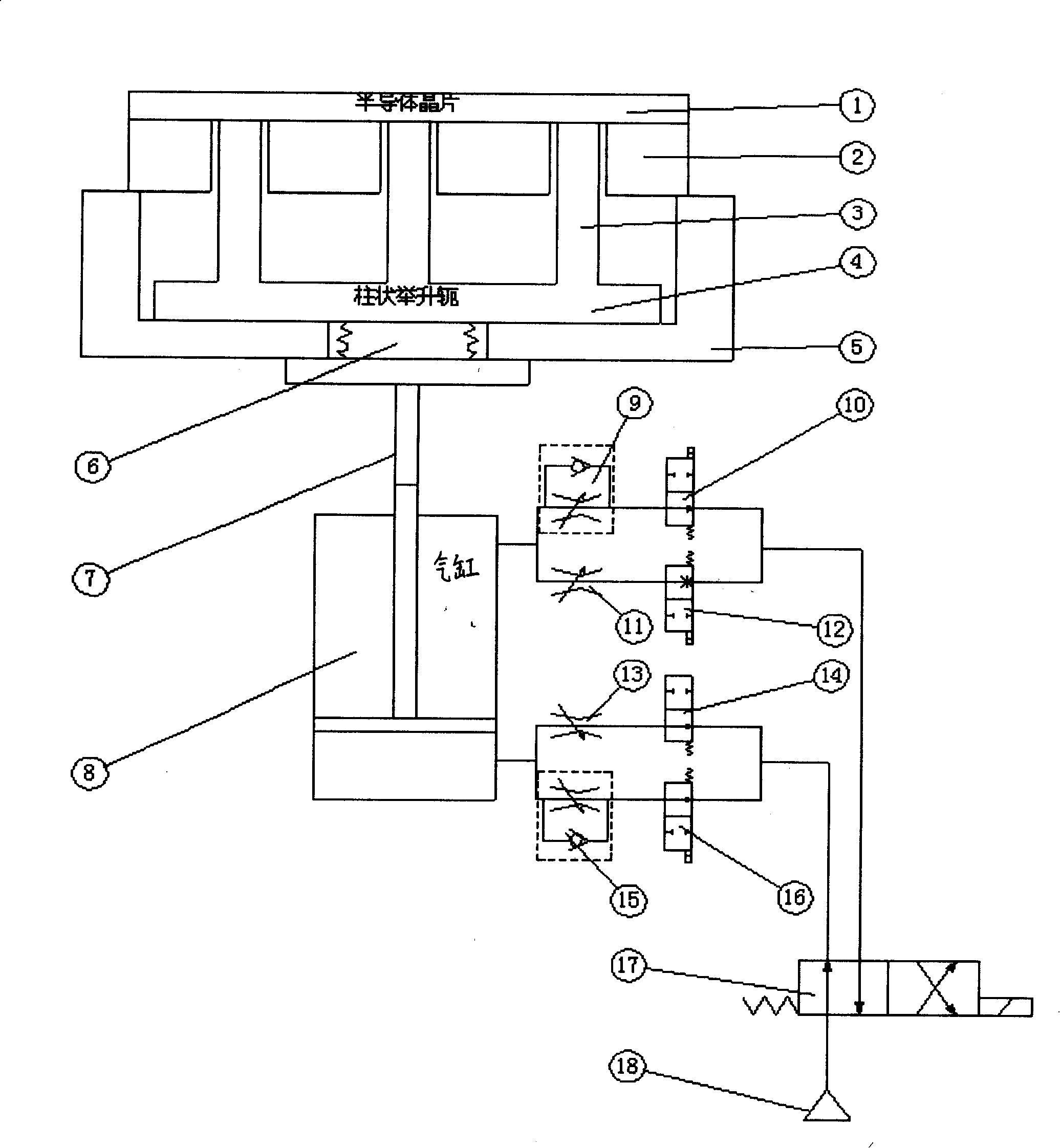

[0027] The core of the present invention is to set a control device in the pneumatic control system of the double-acting cylinder, through which the flow rate of the air flow in the intake pipeline can be changed to realize the control of the moving speed of the cylinder piston, so as to realize the process of wafer seating and unseating. The action is slow first and then fast, so as to prevent the damage caused by the impact of the wafer during the movement. At the same time, the time and cycle of wafer processing can be shortened.

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings of specific embodiments of the present invention.

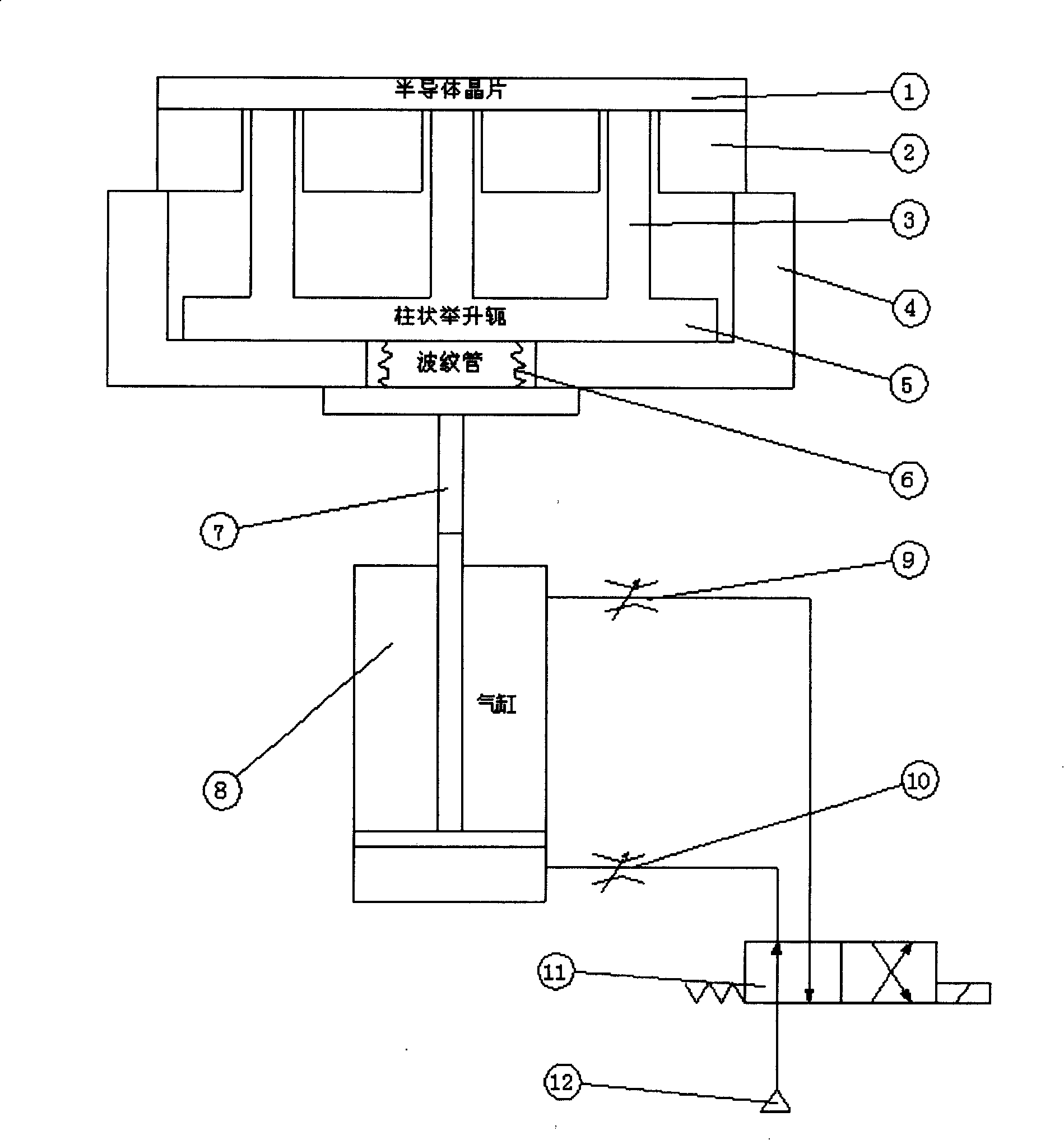

[0029] Such as image 3 As shown, it is a schematic structural diagram of a wafer lifting device according to an embodiment of the present invention. The structure of the wafer lifting device includes a columnar lifting structure 3 connected to each other, a columnar lifting yoke 5, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com