Positive cycle and reverse circulation dual-purpose three teeth roller bit

A technology of reverse circulation and tri-cone, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc. It can solve the problem that the bit cannot be automatically converted into a positive circulation flow channel or a reverse circulation flow channel, and the direction of fluid circulation cannot be automatically changed, etc. problem, to achieve long life and expand the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

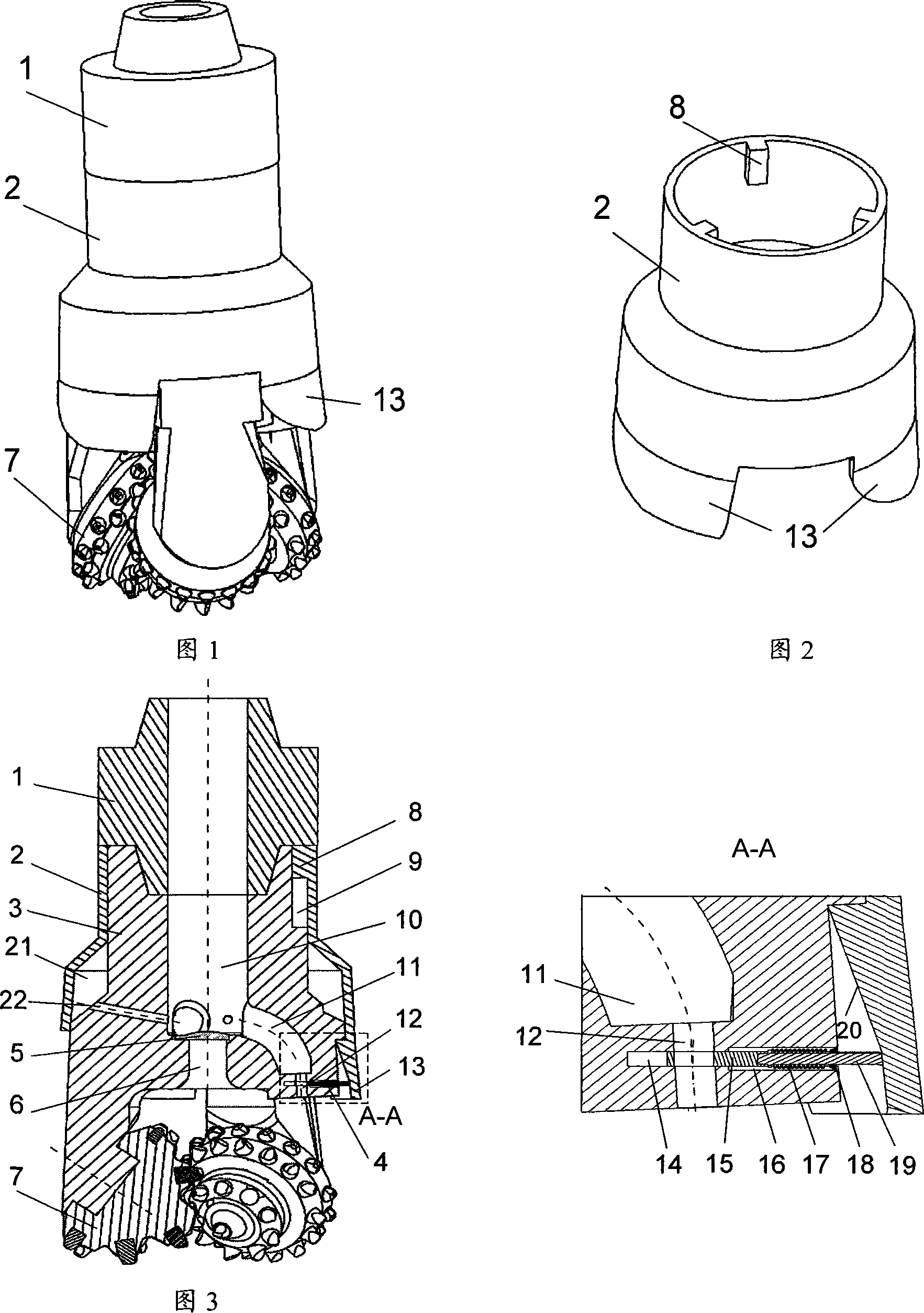

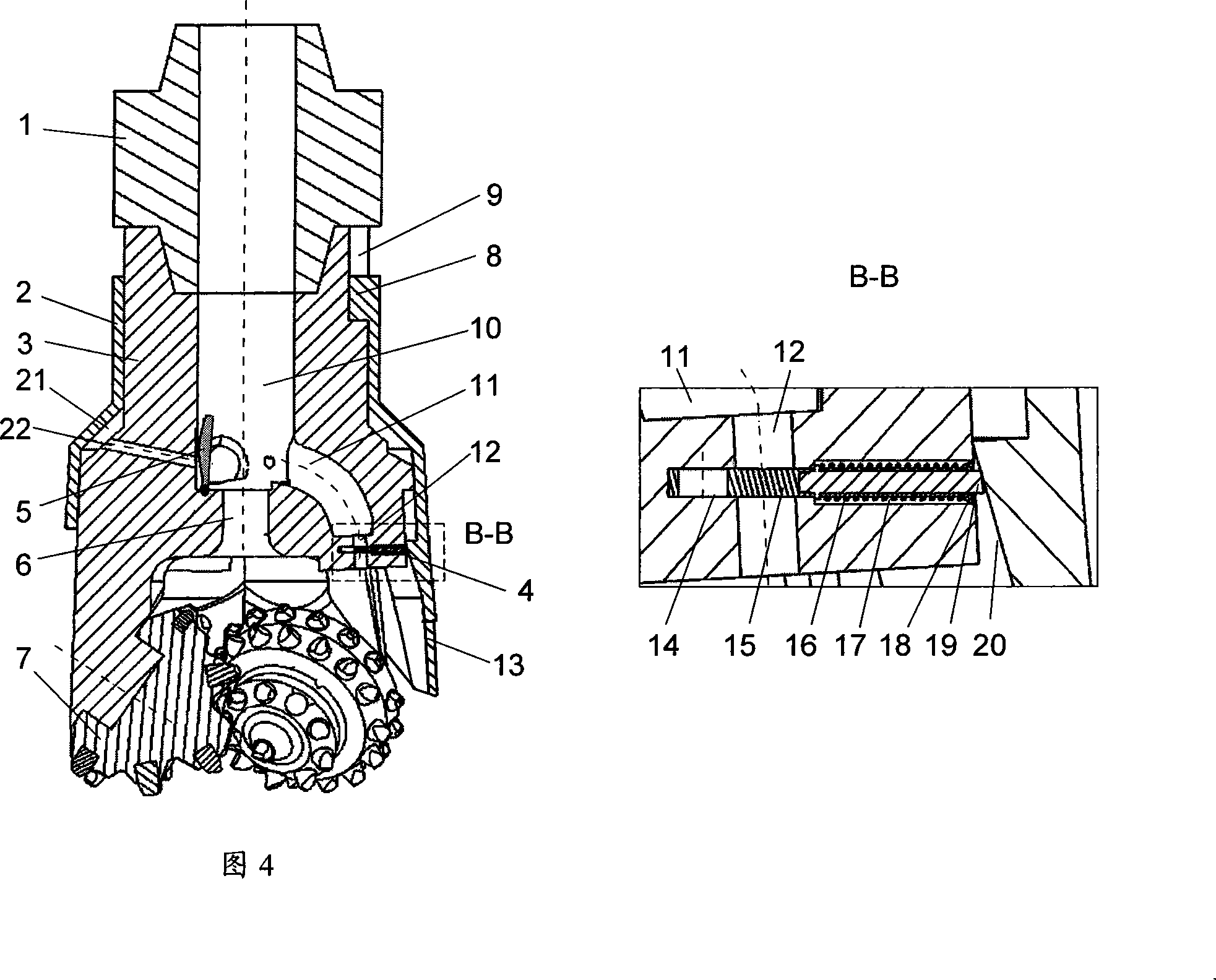

[0015] According to an embodiment of the present invention, a three-cone drill bit for forward circulation and reverse circulation, as shown in Figure 1, Figure 2, Figure 3, and Figure 4, mainly consists of a conversion joint 1, a reverse circulation drainage cover 2, and a three-cone drill bit. The drill bit body 3, the cone nozzle runner valve 4, and the reverse circulation runner valve 5 are composed. On the reverse circulation drainage cover 2 , as shown in FIG. 2 , there are three convex keys 8 forming 120° each other and three drainage baffles 13 to form. The tricone bit body 3, as shown in Fig. 3 and Fig. 4, consists of a reverse circulation channel 6, three conventional roller cones 7, three keyways 9 forming 120° each other, a conventional roller cone bit channel 10, Flow channel 11, nozzle flow channel 12, three mutually forming 120° sealing cavity fluid channels 22, cone nozzle flow channel valve groove 14, cone nozzle flow channel valve groove 16 are formed. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com