Metal shell and its making method

A metal casing and manufacturing method technology, which is applied to metal casings, other manufacturing equipment/tools, electrical equipment casings/cabinets/drawers, etc., can solve problems such as damage, poor surface wear resistance, complex processing procedures, etc., and achieve a simple manufacturing method. , Improve the anti-slip, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

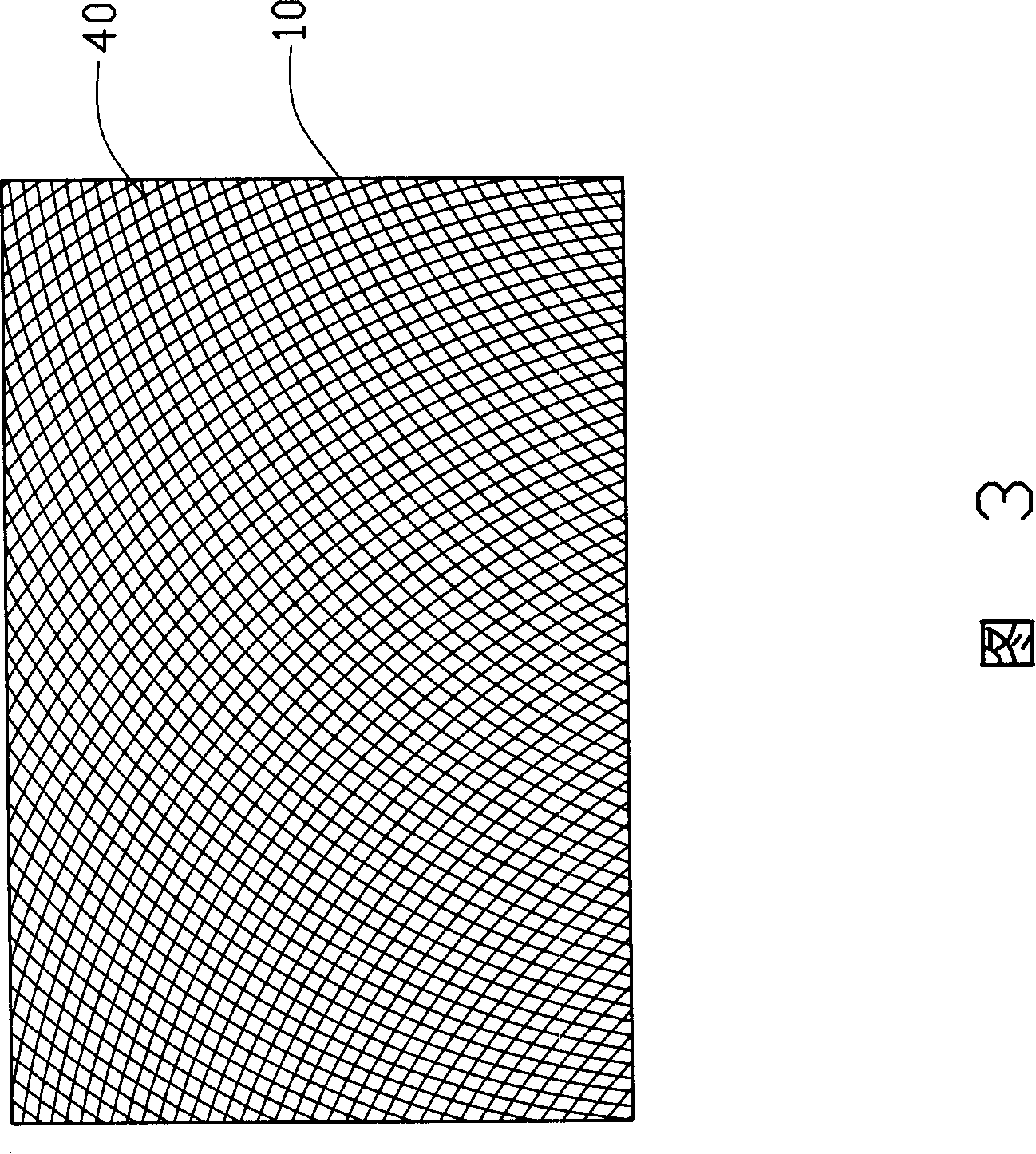

[0017] The present invention provides a metal casing, and a preferred embodiment of the metal casing is applied to a mobile phone.

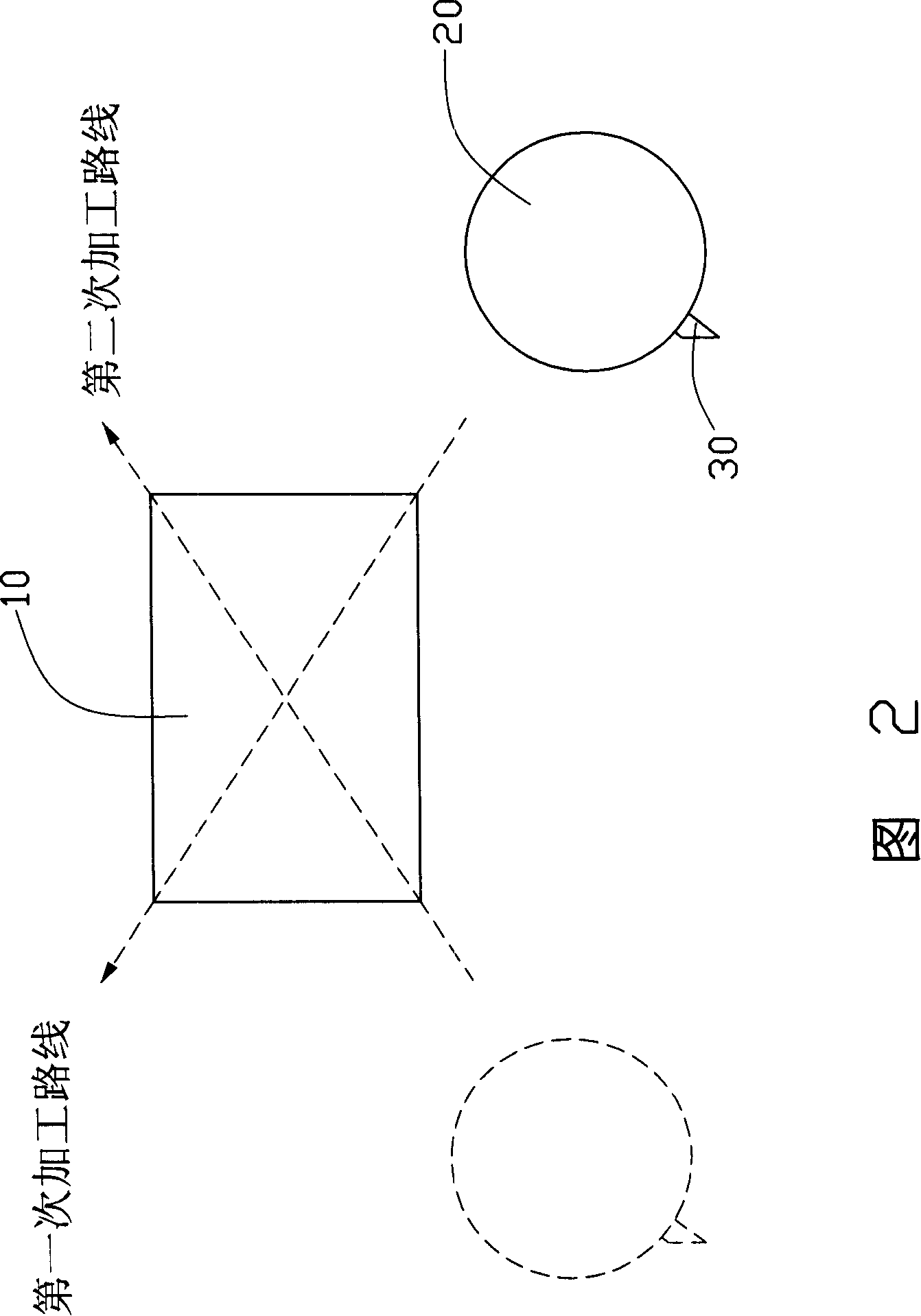

[0018] The surface of the metal shell has the appearance of a knurling pattern, and the knurling pattern can be milled twice in two diagonal directions on the surface of the workpiece through diamond engraving technology, so as to form the appearance of a knurling pattern composed of several rhombuses. The material of the metal shell can be any one or combination of copper, iron, aluminum, stainless steel and titanium, and the material of the metal shell in the preferred embodiment of the present invention is aluminum alloy.

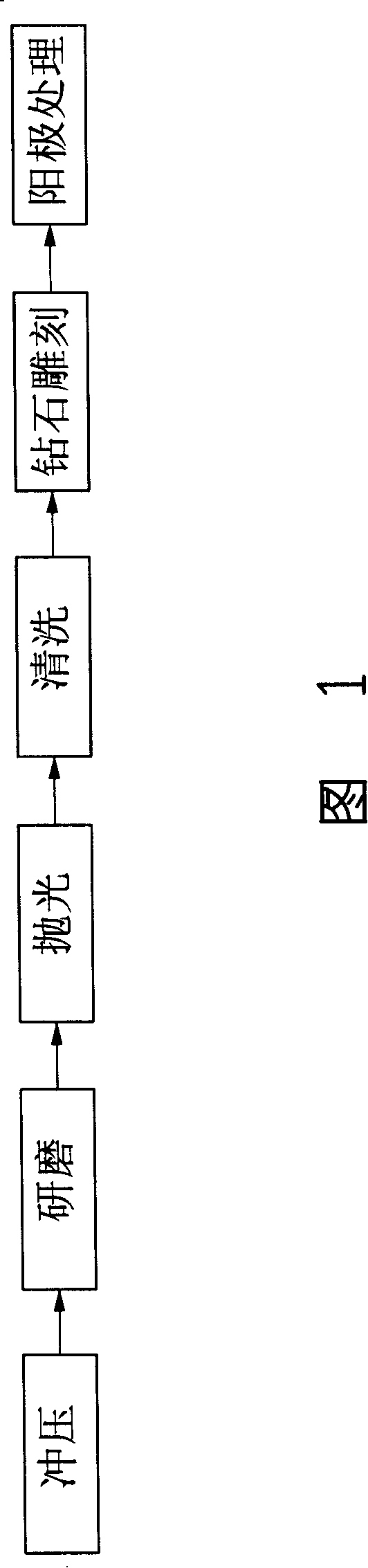

[0019] Please refer to FIG. 1 and FIG. 2 for the manufacturing process and manufacturing method of the metal shell with a knurled surface, which specifically includes the following steps:

[0020] Stamping the metal sheet, the process is to punch the metal sheet through a stamping machine, stretch the edge, and then cut off...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com