Method for establishing electric impedance control line

An impedance control and impedance line technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of labor-intensive time, increase process cost, etc., and achieve the effect of saving time, reducing labor, and good technology inheritance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

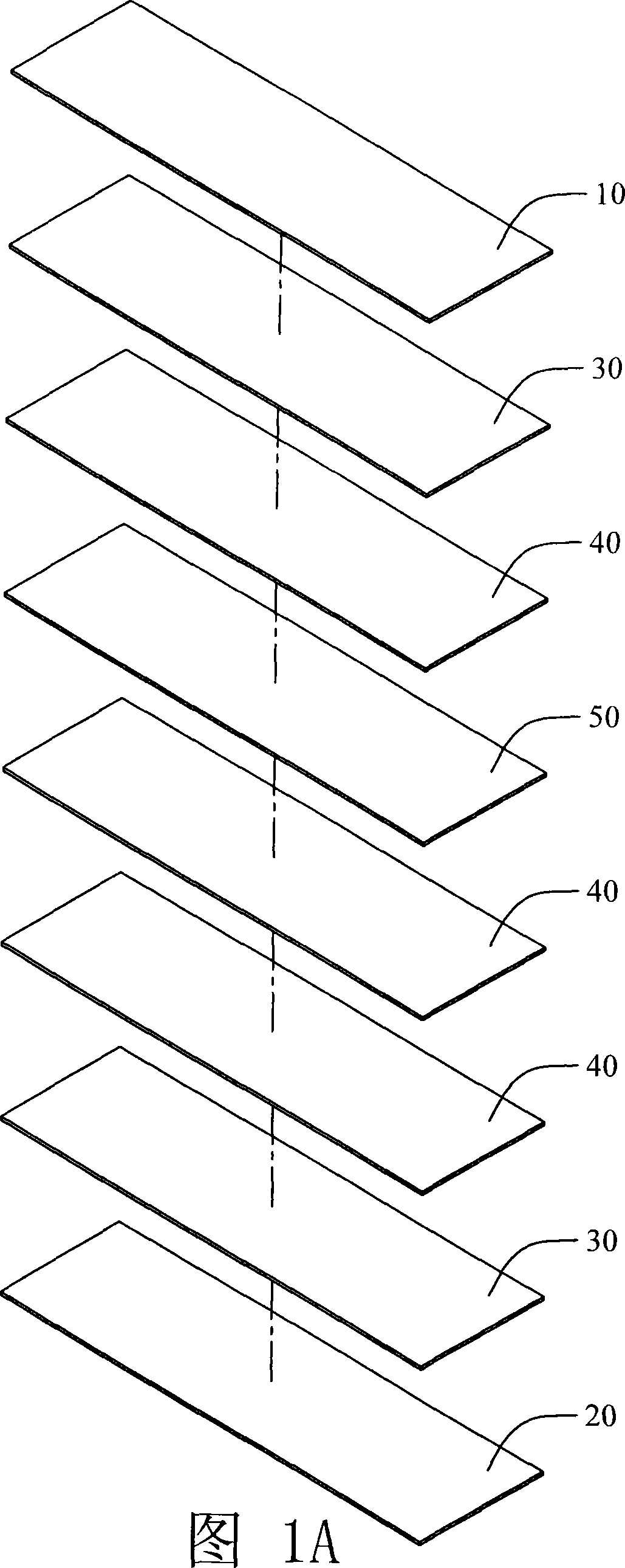

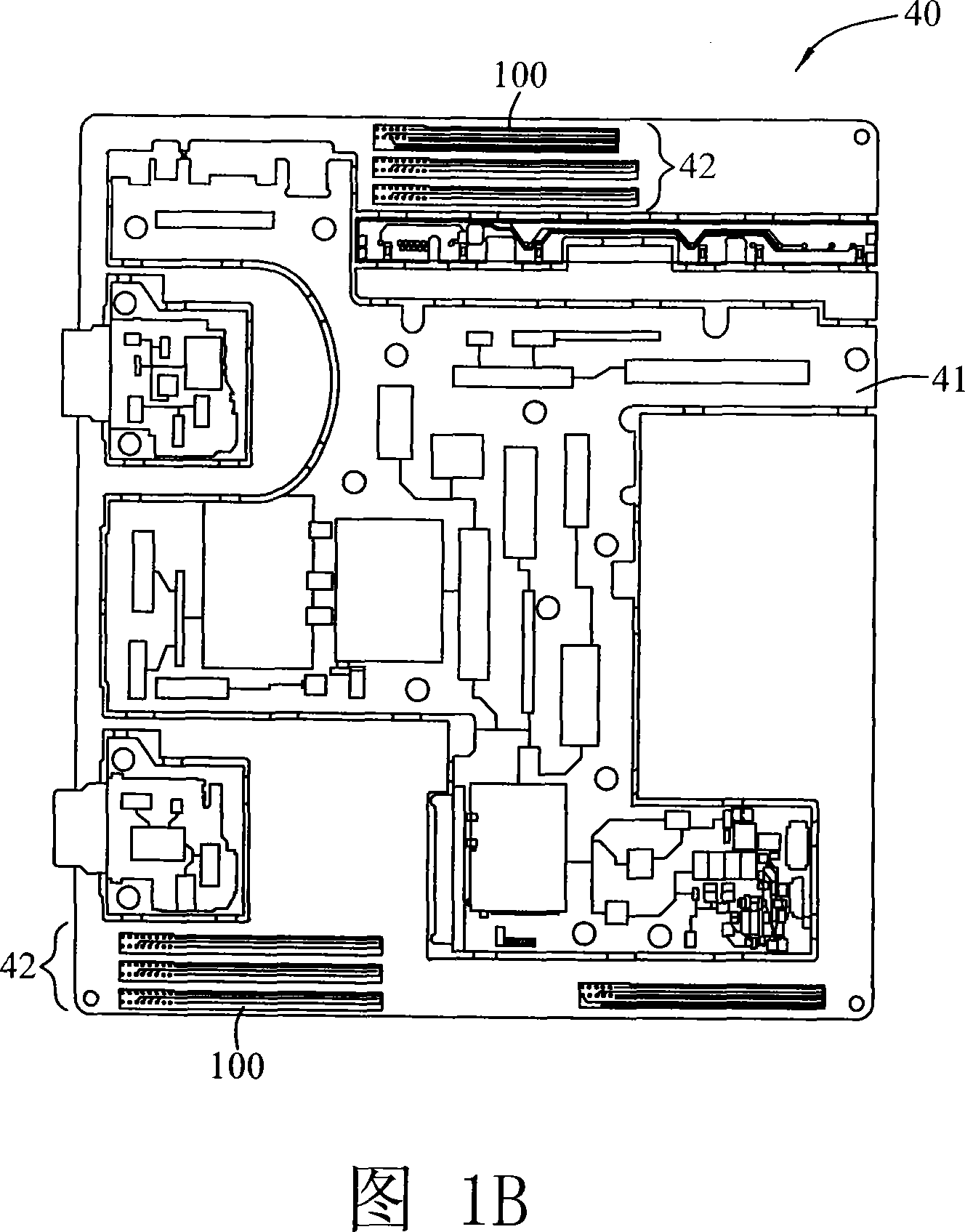

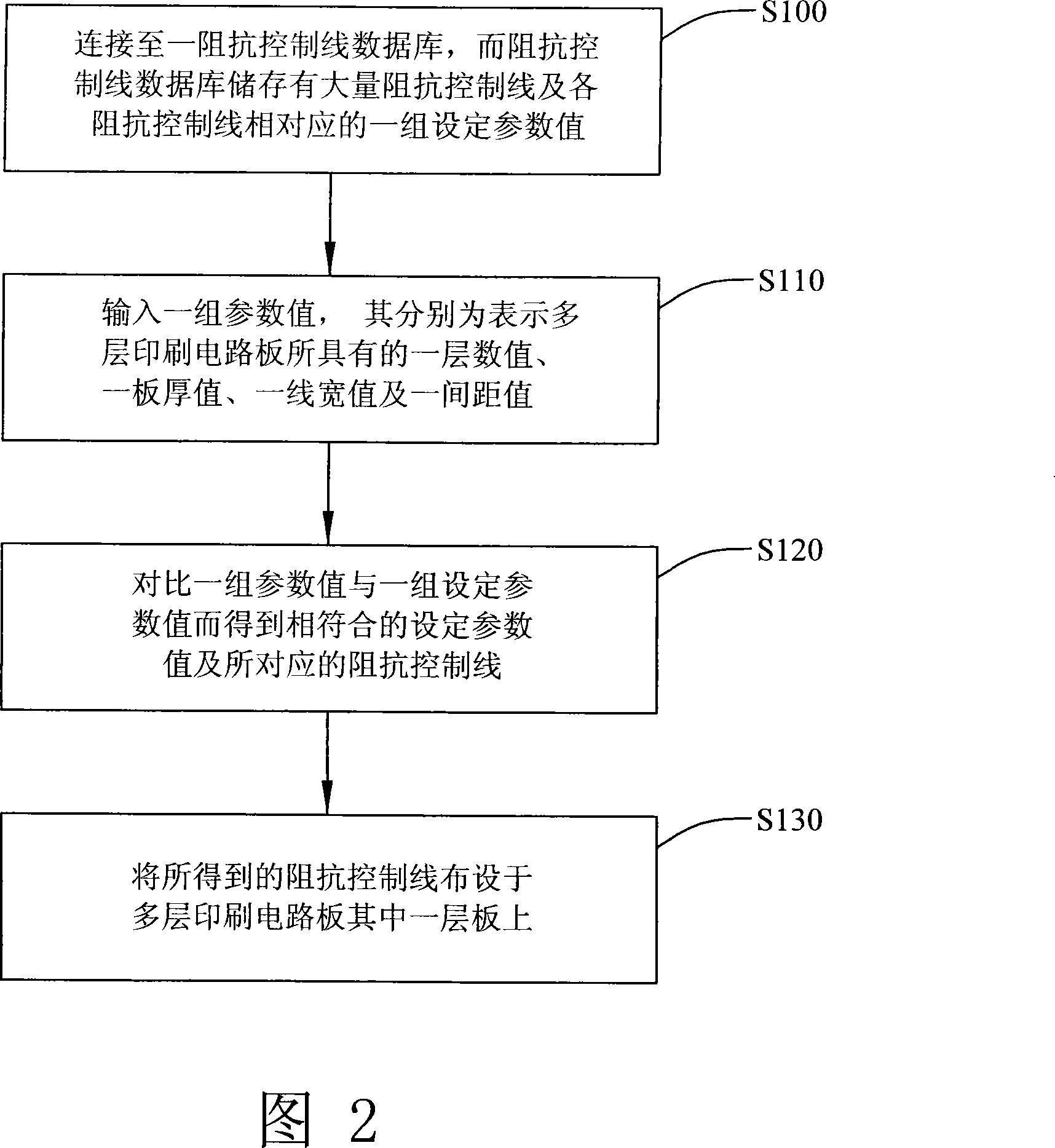

[0031] First, please refer to FIG. 1A and FIG. 1B , FIG. 1A is an exploded schematic diagram of a multilayer printed circuit board. FIG. 1B is a schematic diagram of a circuit board with impedance test leads. This embodiment takes an eight-layer printed circuit board as an example, which includes a top layer 10 , a bottom layer 20 , a plurality of ground layers 30 , a plurality of signal layers 40 and a power layer 50 . Each layer is provided with finely connected circuit wiring. As shown in FIG. 1B, in the present invention, taking a signal layer 40 as an example, the signal layer 40 has a circuit area 41 and a test area 42, and the circuit area 41 has circuit wirings that are finely connected to each layer, which is the signal layer 40. The main working area of the circuit board, and the test area 42 is provided with a plurality of impedance control lines 100, which are commonly grounded with the circuit area 41, but are not directly electrically connected. When the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com