Assembly jig for detachable steel structure construction

A steel structure construction and disassembly technology, which is applied in the direction of scaffolding, house structure support, house structure support, etc., can solve the problems of low reuse rate, waste of materials, difficult to control deformation and displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

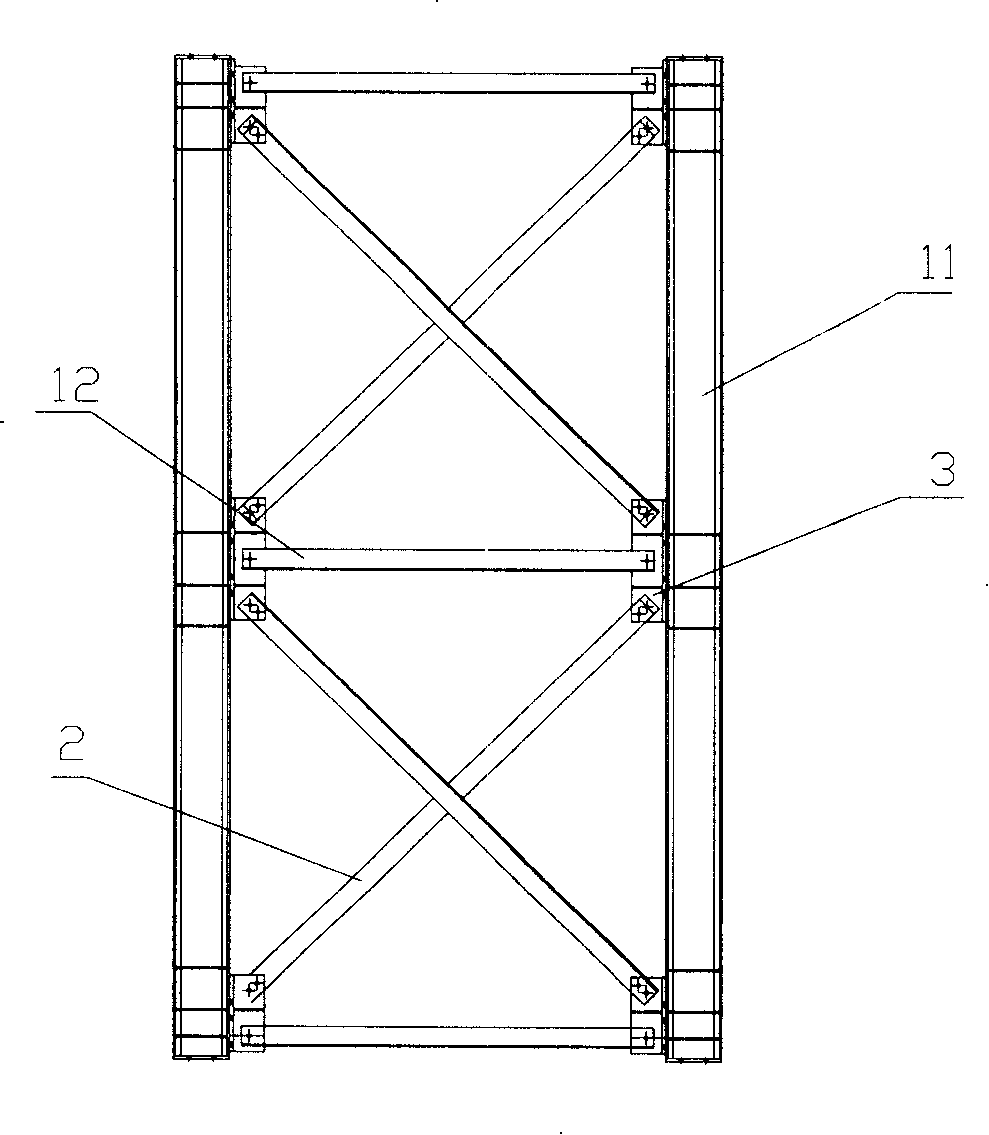

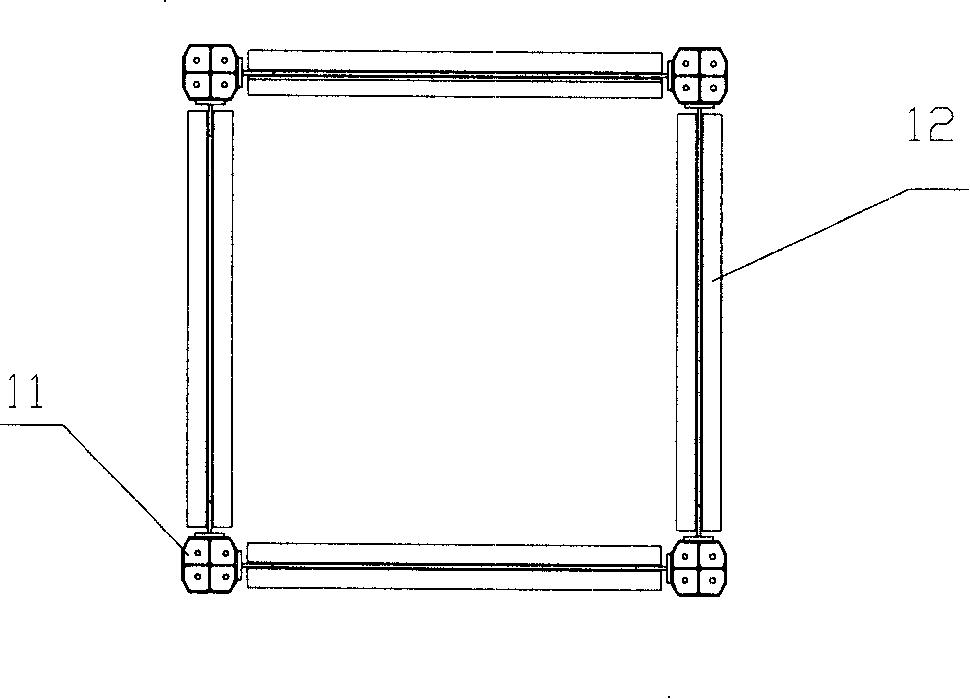

[0019] Such as figure 1 with figure 2 Shown: a tire frame for detachable steel structure construction, including main limbs, slanting parts 2 and connectors 3, said main limbs include several sectioned steel as upright braces 11 and horizontal braces 12, said The connectors 3 are arranged at both ends of the upright braces 11; the horizontal braces 12 are connected with the adjacent upright braces 11 through the connectors 3 to form several hexahedrons; The connecting piece 3 is connected between the upright brace 11 and the horizontal brace 12; the upright brace 11 between two adjacent regular hexahedrons is connected by bolts.

[0020] The connecting piece is a plate on both ends of the upright support 11 and integrally connected therewith.

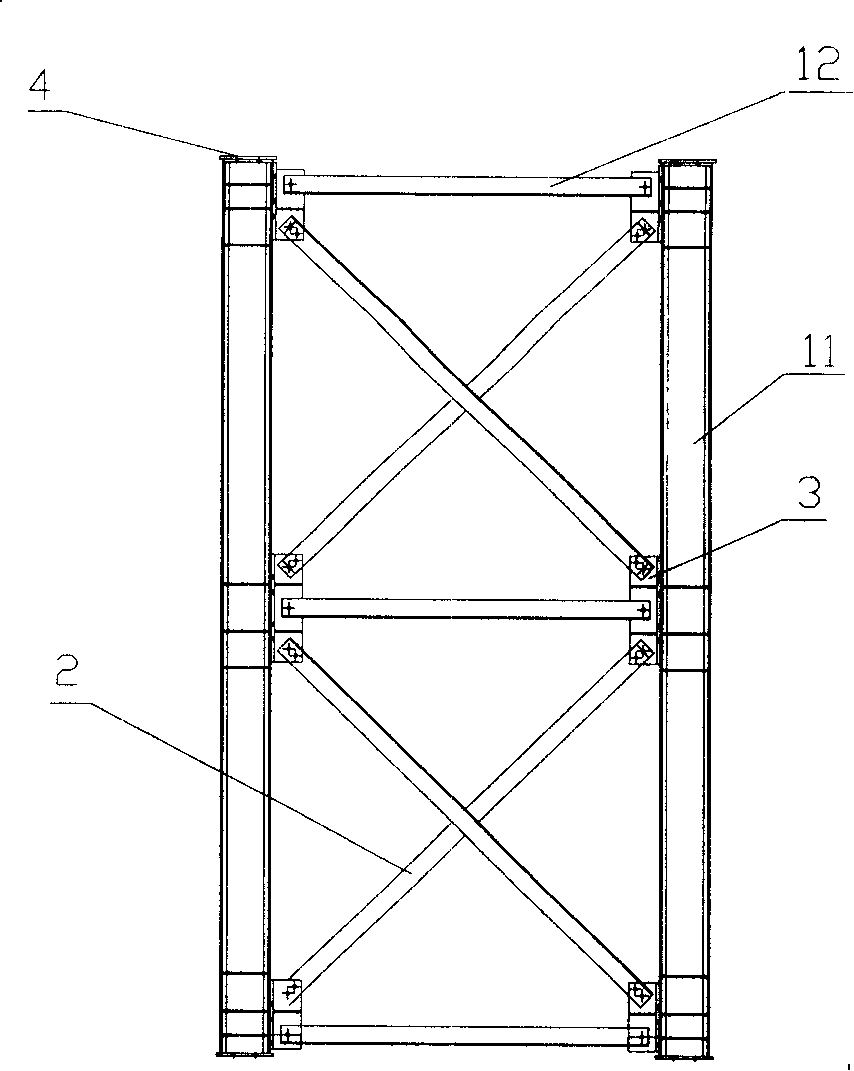

[0021] image 3 with Figure 4 Another embodiment of the present invention is shown, as can be seen in the figure: the upper and lower ends of the upright brace 11 are provided with plate-shaped connecting plates 4, and the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com