Golf bag with integral bag body

A golf bag and bag body technology, which is applied to golf club bags, golf balls, rackets, etc., can solve the problem of poor deformation resistance, and achieve the effects of improving deformation resistance, reducing weight and reducing management costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

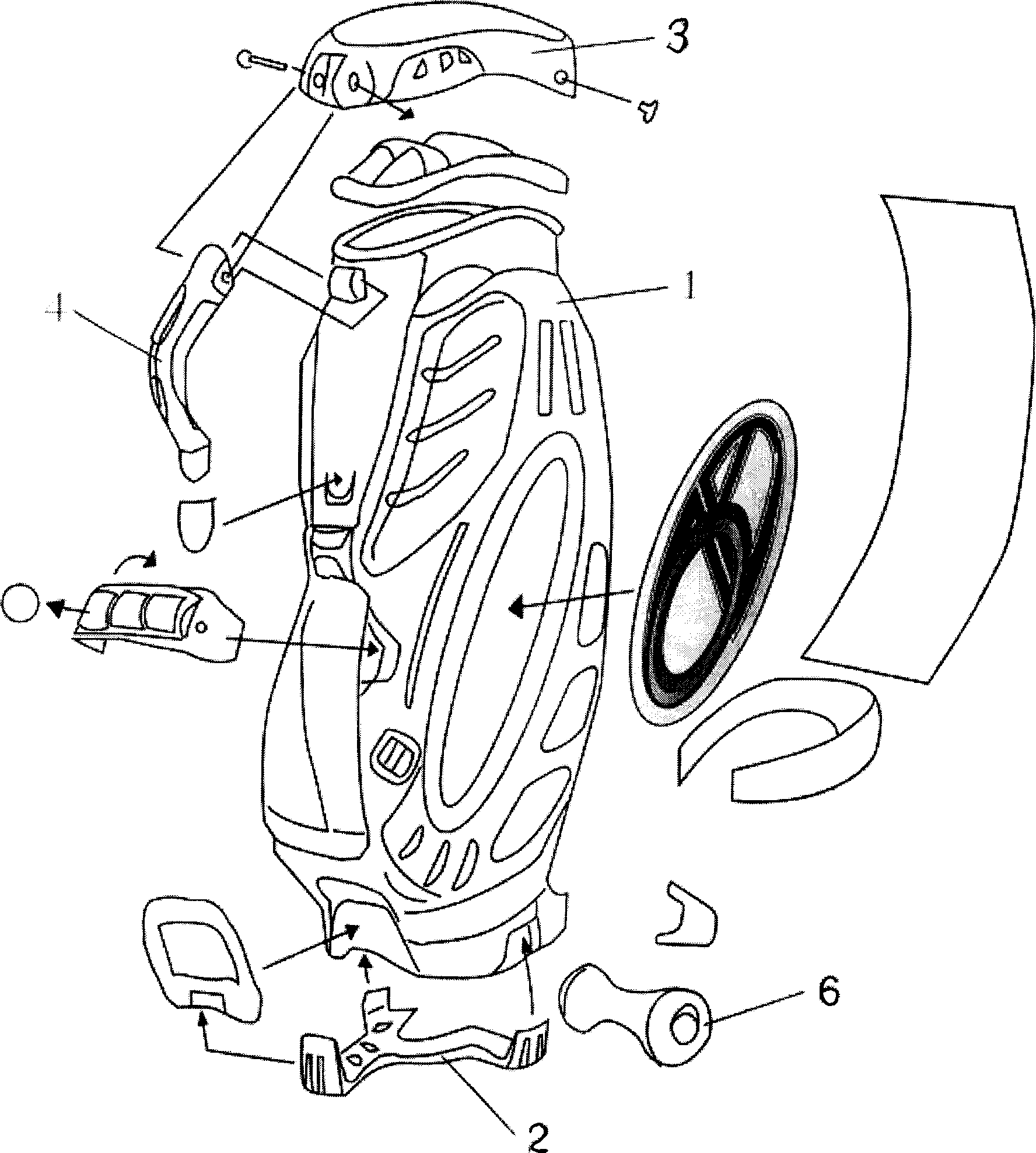

[0027] The embodiments of the present invention will be further described below in conjunction with the drawings.

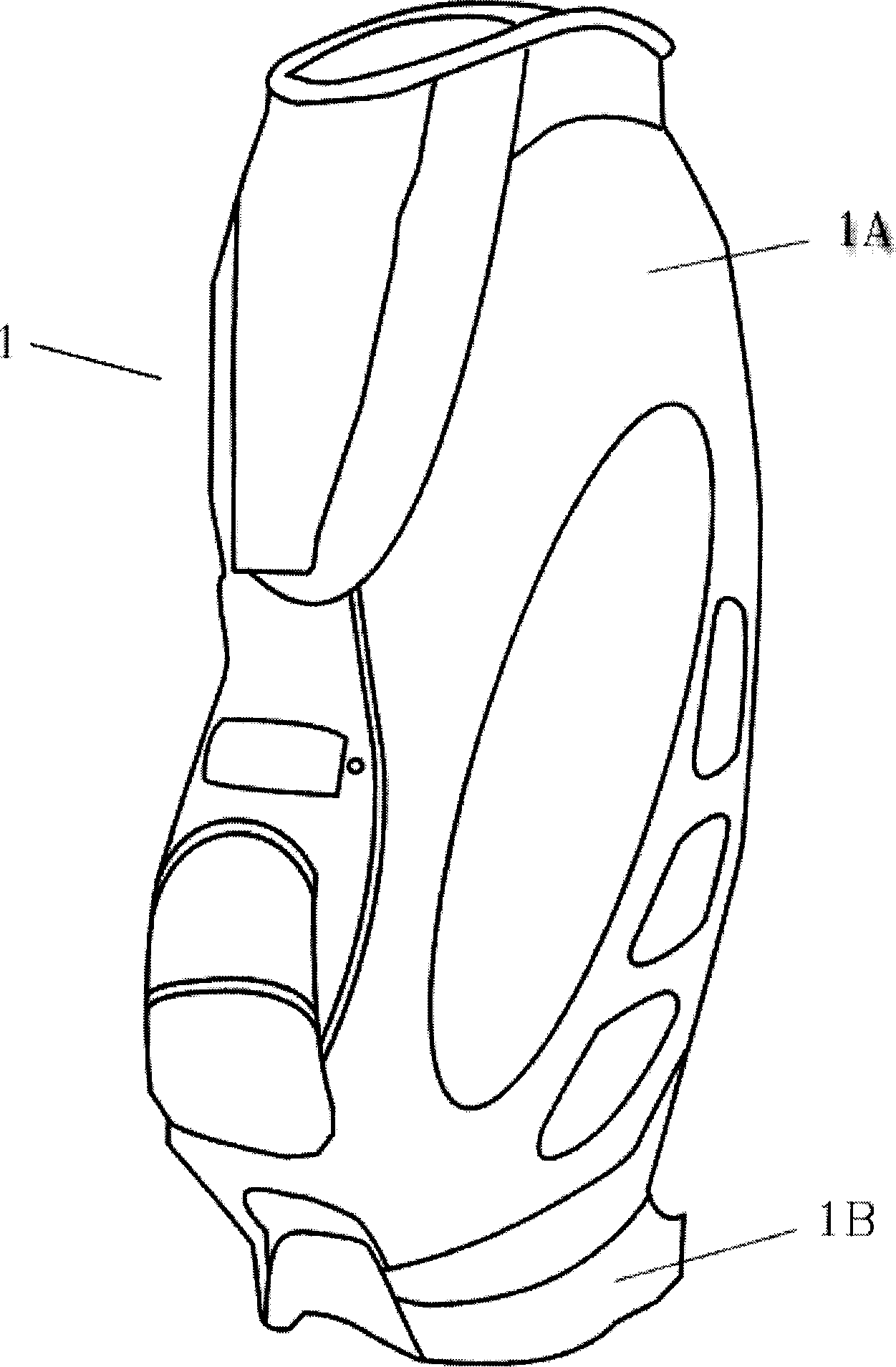

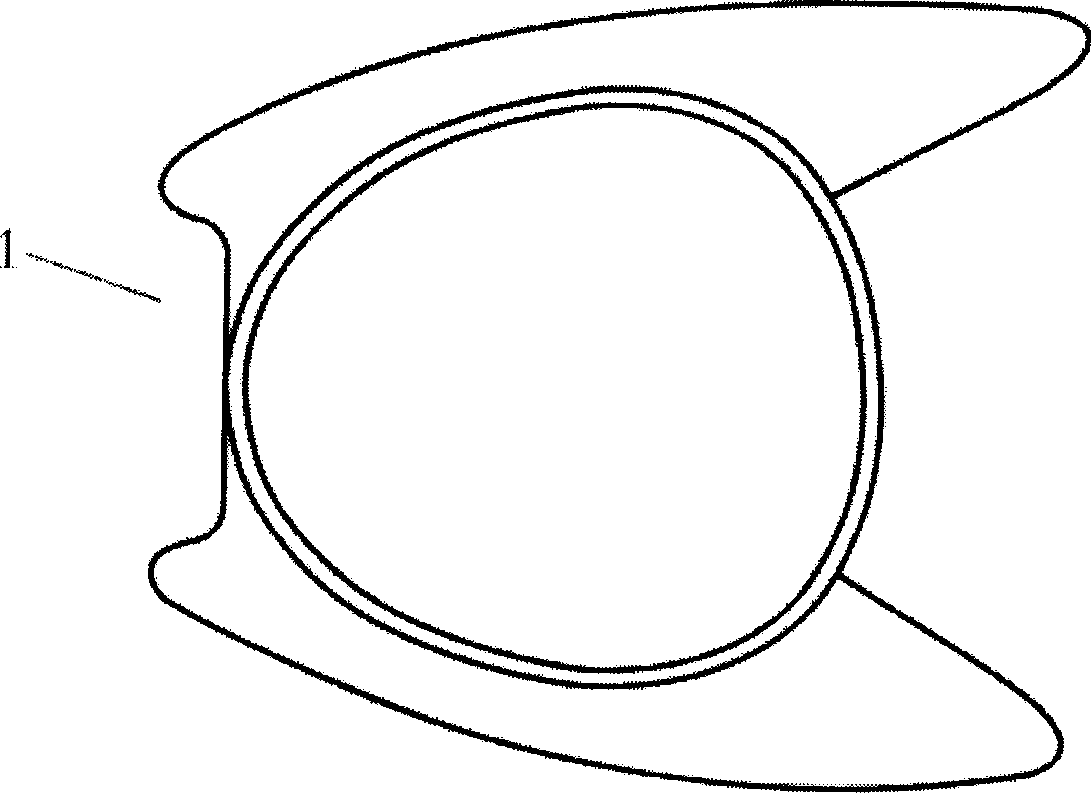

[0028] figure 1 This is a schematic diagram of the blow-molded cylindrical bag body 1 of the first embodiment of the golf bag with a whole body of the present invention. figure 2 It is a top view. In the figure, the cylindrical bag body 1 is integrally formed by a blow molding process and is shaped like a special-shaped thin-walled container with a wall thickness of less than 1 mm. The cylindrical surface 1A of the cylindrical bag body 1 and the bottom surface 1B of the cylindrical bag body 1 are blow-molded at the same time.

[0029] Blow molding is the main method of making hollow plastic products. The processing process mainly includes: fixing the end of a plastic tube that is softened by heating; inflating the plastic tube to expand and attach to the inner surface of the mold; using conductive or volatile fluid volatilization The role of the product cooling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com