Paper-making black liquor fluidized bed alkali reclaiming device and method

A papermaking black liquor and fluidized bed technology, applied in the direction of concentrating waste liquid, etc., can solve problems such as bed material coking, and achieve the effects of solving agglomeration, reducing operating costs, and solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

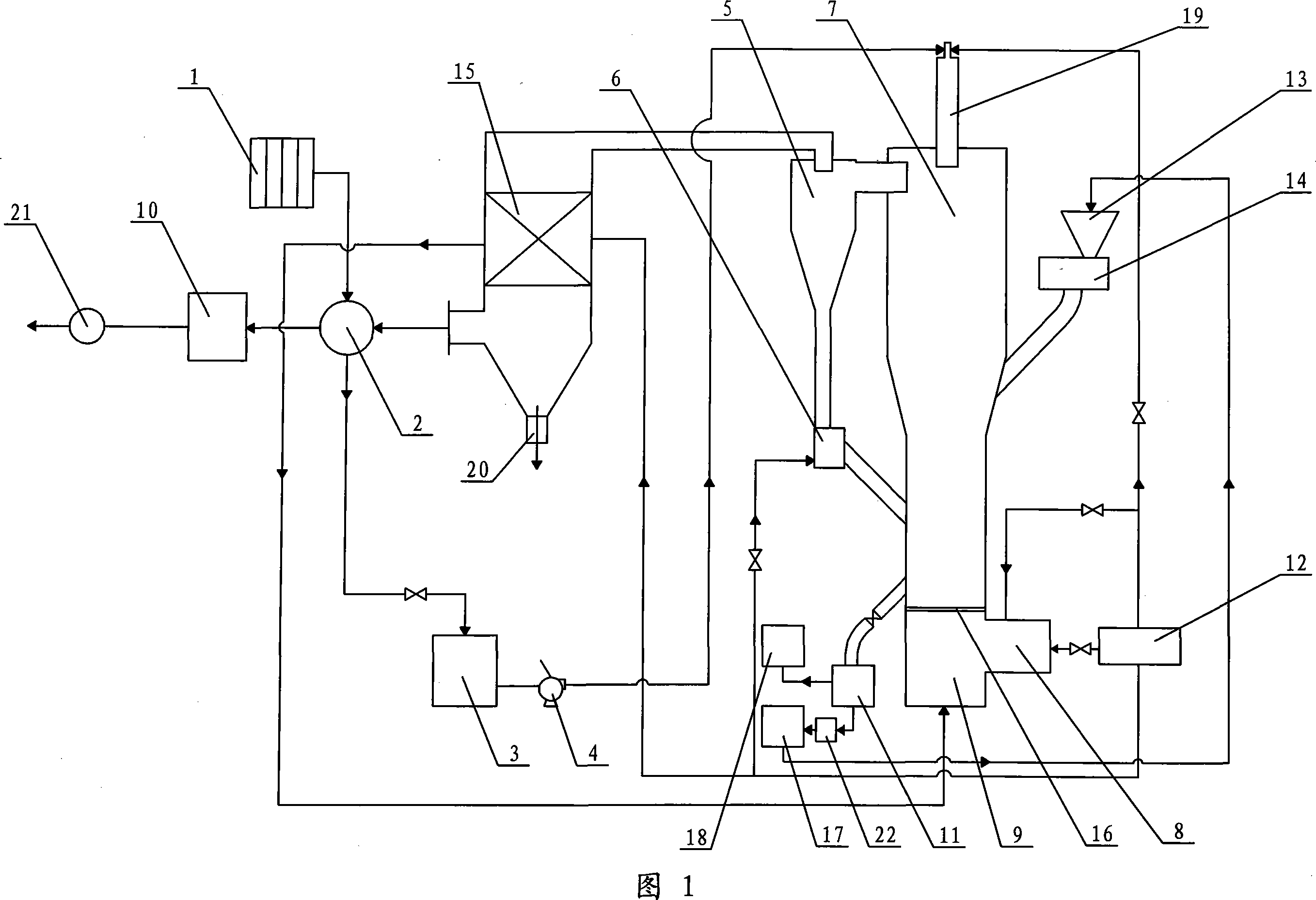

[0008] Specific embodiment one: this embodiment is described in conjunction with Fig. 1, and this embodiment consists of multi-effect evaporator 1, disk evaporator 2, thick black liquor tank 3, black liquor pump 4, cyclone separator 5, material leg 6, flow Chemical bed alkali recovery furnace 7, burner 8, air chamber 9, electrostatic precipitator 10, dissolution tank 11, blower 12, silo 13, twisted cage 14, air preheater 15, air distribution plate 16, dryer 17, Causticizer 18, spray gun 19, induced draft fan 21 and chain plate slag extractor 22, multi-effect evaporator 1 communicates with disc evaporator 2 through pipeline, and disc evaporator 2 communicates with thick black liquor tank 3 through pipeline The thick black liquor tank 3 communicates with the black liquor pump 4 through the pipeline, and the black liquor pump 4 communicates with the spray gun 19 through the pipeline. The spray gun 19 is arranged on the top of the fluidized bed alkali recovery furnace 7, and the bo...

specific Embodiment approach 2

[0009] Specific embodiment two: present embodiment is illustrated in conjunction with Fig. 1, and the method of present embodiment is accomplished like this: the dilute black liquor that contains solid matter 8%-10% is concentrated to 25~30% through multi-effect evaporator 1, then passes through The disk evaporator 2 concentrates the black liquor to 40-45%, and the concentrated black liquor is sent to the spray gun 19 under the action of the black liquor pump 4, and then sent to the fluidized bed alkali recovery furnace 7 for incineration after being atomized. At the same time, using sodium-based zeolite as the bed material, the bed material is put into the silo 13, and the bed material enters the fluidized bed alkali recovery furnace 7 through the twisted cage 14, and the furnace temperature is controlled at 700-900°C. Using sodium-based zeolite as the bed material can ensure that the bed material does not coke, and the inorganic sodium salt and bed material produced by burnin...

specific Embodiment approach 3

[0010] Embodiment 3: The particle size of the sodium-based zeolite in this embodiment is 200-2000 μm. The particle gap in this range is small, and it is easier to form fluidization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com