Driving apparatus and image pickup apparatus

A technology of driving device and camera device, applied in installation, generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, etc., can solve the problems of bulkiness, violation of miniaturization, complex mechanism, etc., and achieve high efficiency The effect of high and high driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the best mode for implementing the driving device and the imaging device according to the present invention will be described with reference to the drawings. The imaging device of this embodiment is equipped with a driving device for performing hand shake correction of an imaging unit including an imaging element that obtains an image signal by photoelectric conversion. An application example of an electronic camera (digital camera) will be described. In addition, the present invention is not limited to the embodiments, and various modifications can be made as long as they do not depart from the gist of the present invention.

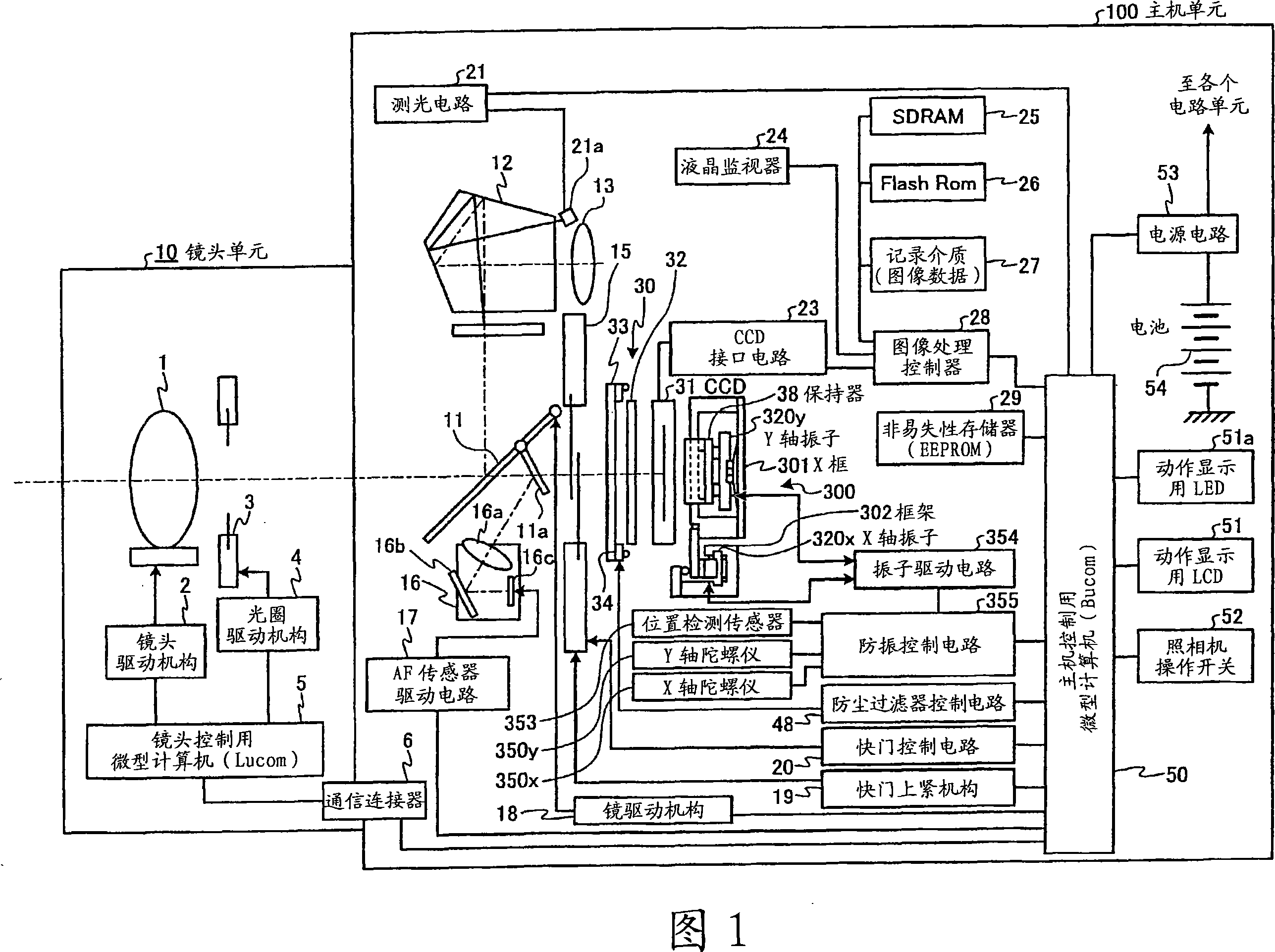

[0029] First, a configuration example of a camera system according to the present embodiment will be described with reference to FIG. 1 . FIG. 1 is a block diagram schematically showing the configuration of main electrical systems of a camera according to this embodiment. The camera of the present embodiment is systematically compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com