Multi-point repeat process step monitoring counter

A counter and working step technology, applied in the direction of instruments, simulators, program control, etc., can solve the problems of missing operation monitoring, material consumption statistics, etc., to achieve the effect of avoiding material waste, convenient use, and improving production management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

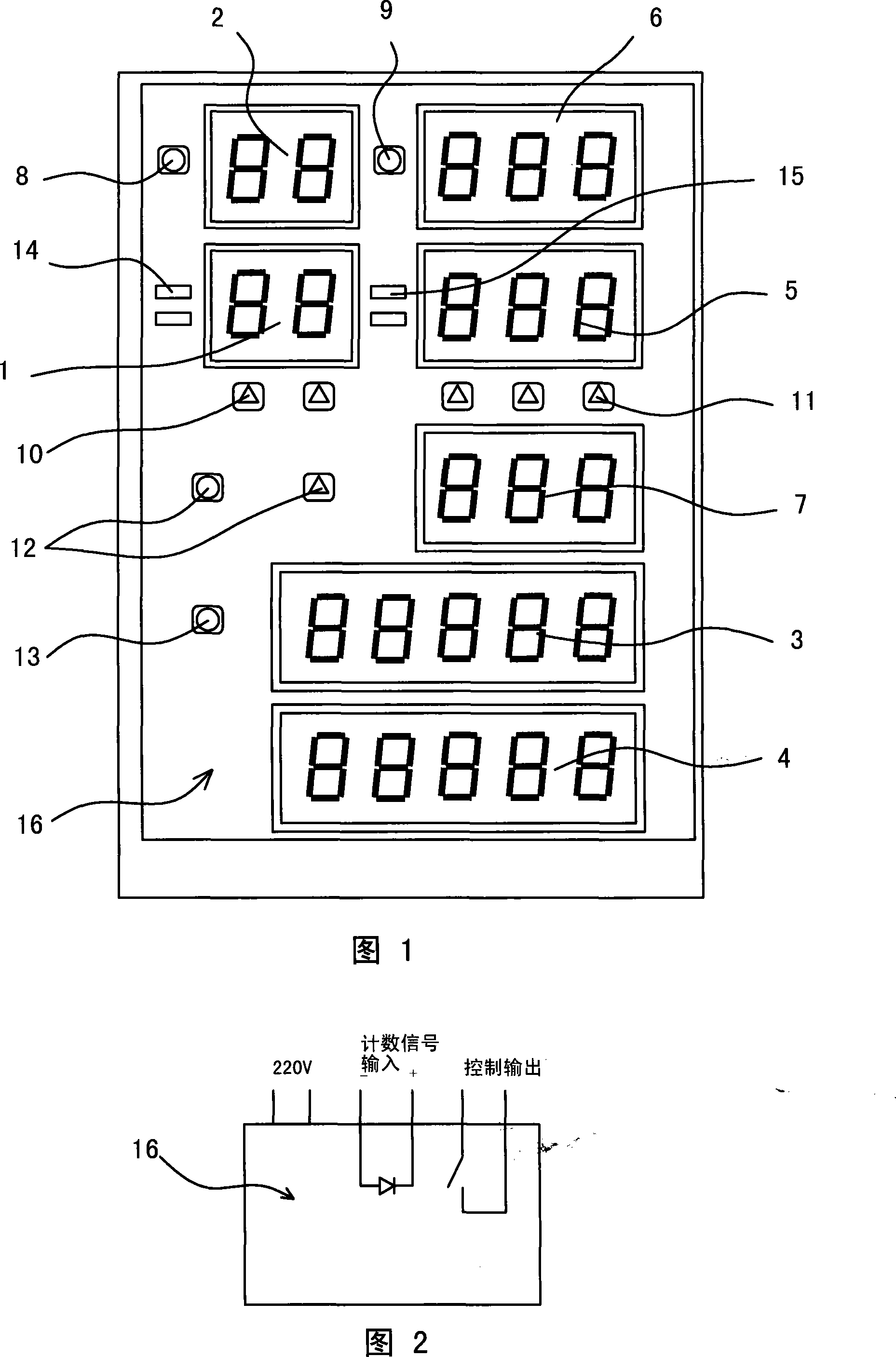

[0034] Embodiment 1: A multi-point repetitive work step monitoring counter

[0035] As shown in Figure 1, it is composed of a group of interrelated counters, each of which has a display window. The set of counters are respectively:

[0036] 1. The first counter 1

[0037] The first counter 1 is used as a preset counter for the number of repeated work steps, and a natural positive integer n greater than 1 is set through the preset button 10 as the number of repeated work steps that each operation object needs to complete in a certain process.

[0038] 2. The second counter 2

[0039] The second counter 2 is used as a countdown counter for the number of repeated steps, and records the remaining number of repeated steps of the current operation object in the process. The initial value of the second counter 2 is equal to the set value n of the first counter 1, and the corresponding operation equipment generates a count signal every time a repeated work step is completed, and th...

Embodiment 2

[0067] Embodiment 2: A multi-point repetitive work step monitoring counter

[0068] This embodiment is composed of the first counter to the sixth counter. The difference from the first embodiment is that the seventh counter is removed. Others are the same as the first embodiment, and will not be repeated here.

Embodiment 3

[0069] Embodiment 3: A multi-point repetitive work step monitoring counter

[0070] This embodiment is composed of the first counter to the fourth counter. The difference from the first embodiment is that the fifth counter to the seventh counter are removed. Others are the same as the first embodiment, and will not be described again here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com