Low energy consumption catalytic conversion method of hydrocarbon oil

A catalytic conversion method and technology with low energy consumption, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of increasing catalyst consumption, increasing catalyst aging and deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

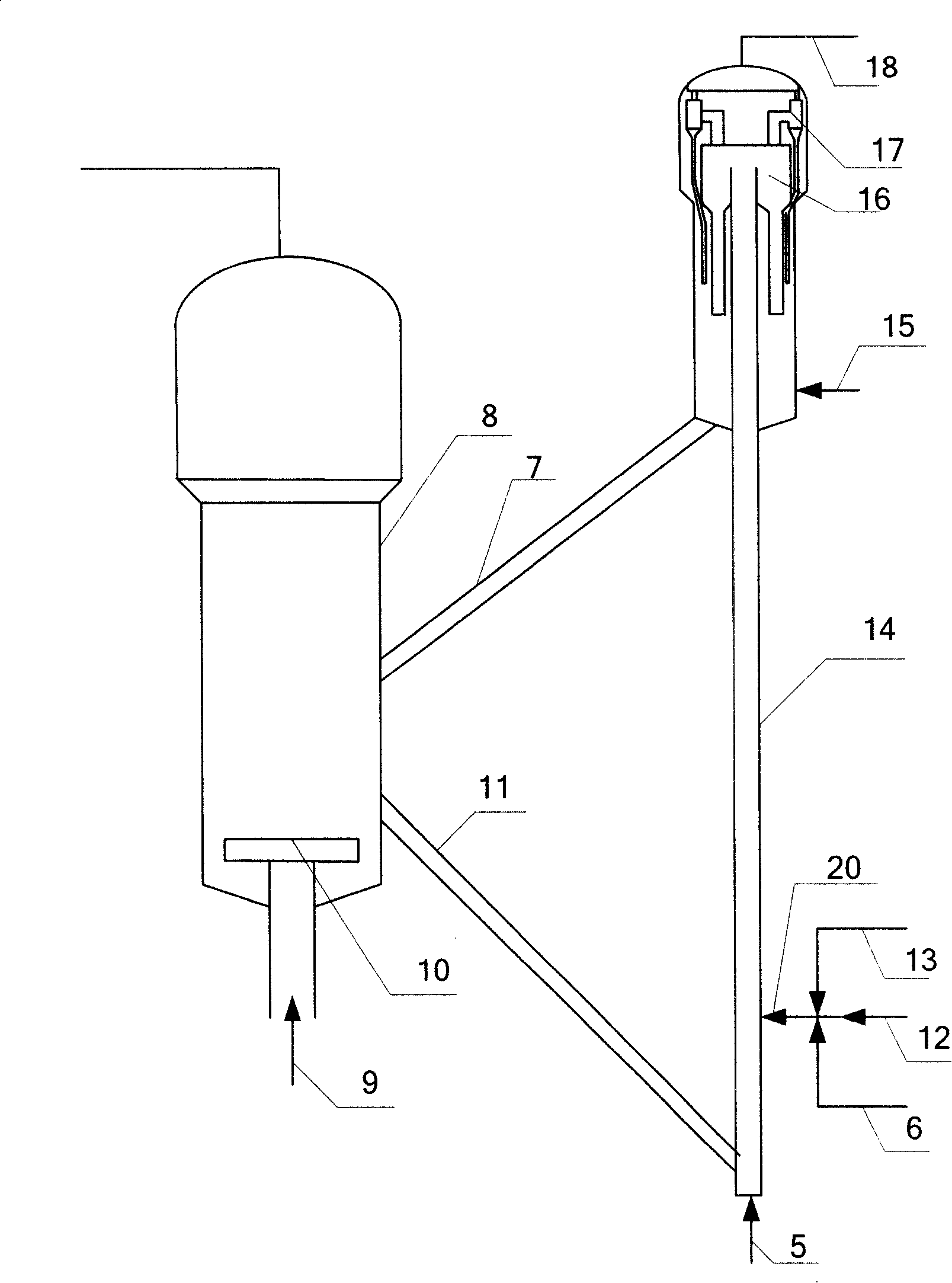

Image

Examples

Embodiment

[0030] Adopt the same reactor as comparative example, reaction process and product analysis method. The atomization steam volume of raw oil is 1000g / h, and 4000g / h propane is added as the atomization medium. The properties of the raw materials used are shown in Table 1, and the properties of the catalyst used are shown in Table 2. The main operating conditions and product distribution are shown in Table 3.

[0031] It can be seen from Table 3: compared with the comparative example, the amount of atomized steam is reduced from 3000g / h to 1000g / h, and 4000g / h propane is added as the atomized medium. From the perspective of product distribution, the dry gas production rate increases by 0.4 percentage points , the yield of liquefied gas decreased by 1.4 percentage points, the yield of gasoline increased by 0.3 percentage points, the yield of diesel oil increased by 0.4 percentage points, the yield of coke was not much different, the yield of propylene increased by 0.2 percentage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com