Special control-release fertilizer for resin coated grassplot and preparation thereof

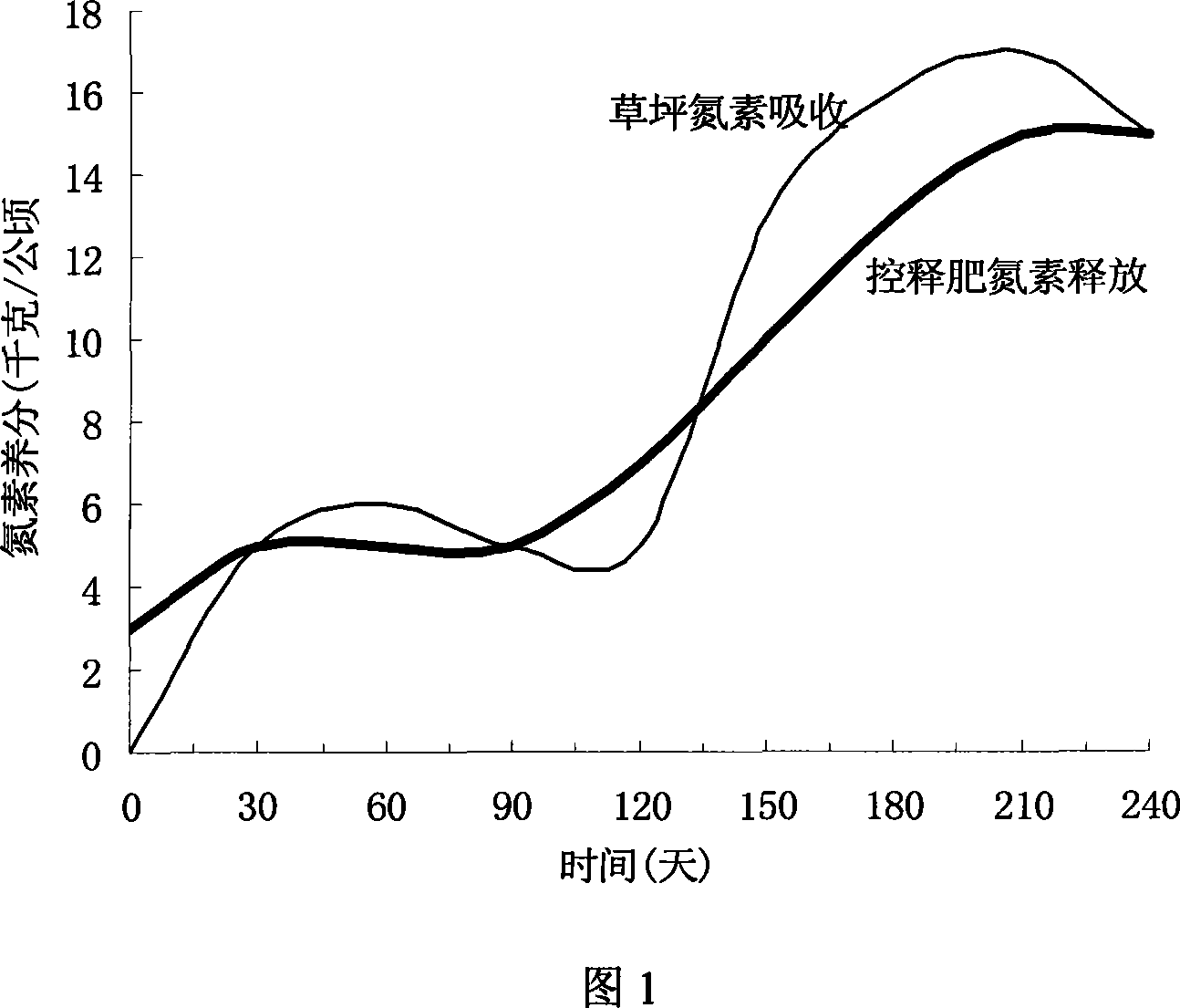

A resin-coated, controlled-release fertilizer technology, applied in fertilization methods, applications, nitrogen fertilizers, etc., can solve the problems of high price, turf nutrient element ratio, and poor nutrient release rules, so as to achieve stable nutrient supply and improve fertilizer utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Controlled-release fertilizer for lawn, total nutrients: nitrogen, phosphorus pentoxide and potassium oxide content are 30%, 6%, and 11% by mass, respectively. The raw material components are as follows:

[0051] 6% thermoplastic resin coated potassium nitrate 115kg

[0052] 7% thermoplastic resin coated potassium nitrate 100kg

[0053] 6% thermoplastic resin coated ammonium phosphate 45kg

[0054] 7% thermoplastic resin coated ammonium phosphate 45kg

[0055] 4% thermoplastic resin coated urea 150kg

[0056] 5% thermoplastic resin coated urea 140kg

[0057] 6% thermoplastic resin coated urea 120kg

[0058] 7% thermoplastic resin coated urea 80kg

[0059] 8% thermoplastic resin coated urea 80kg

[0060] Potassium chloride compound fertilizer 110kg

[0062] Chelated iron fertilizer 10kg.

[0063] Preparation:

[0064] Put the above raw materials into a mixer and stir for 5 to 10 minutes, and mix well. Then, the mixed fe...

Embodiment 2

[0065] Example 2: Controlled-release fertilizer for lawn, total nutrients: nitrogen, phosphorus pentoxide and potassium oxide are 26%, 6%, and 16% by mass, respectively. The raw material components are as follows:

[0066] 6% thermoplastic resin coated potassium nitrate 180kg

[0067] 7% thermoplastic resin coated potassium nitrate 150kg

[0068] 6% thermoplastic resin coated ammonium phosphate 45kg

[0069] 7% thermoplastic resin coated ammonium phosphate 45kg

[0070] 4% thermoplastic resin coated urea 130kg

[0071] 5% thermoplastic resin coated urea 125kg

[0072] 6% thermoplastic resin coated urea 100kg

[0073] 7% thermoplastic resin coated urea 50kg

[0074] 8% thermoplastic resin coated urea 50kg

[0075] Potassium chloride compound fertilizer 110kg

[0077] Chelated iron fertilizer 10kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com