Apparatus for braking and linking convex and concave

A linkage device and concave-convex surface technology, applied in the combination of couplings and brakes, mechanical equipment, etc., can solve the problems of small torque, small transmission torque, car crashes, etc., and achieve shortened braking distance and uniform braking force , good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

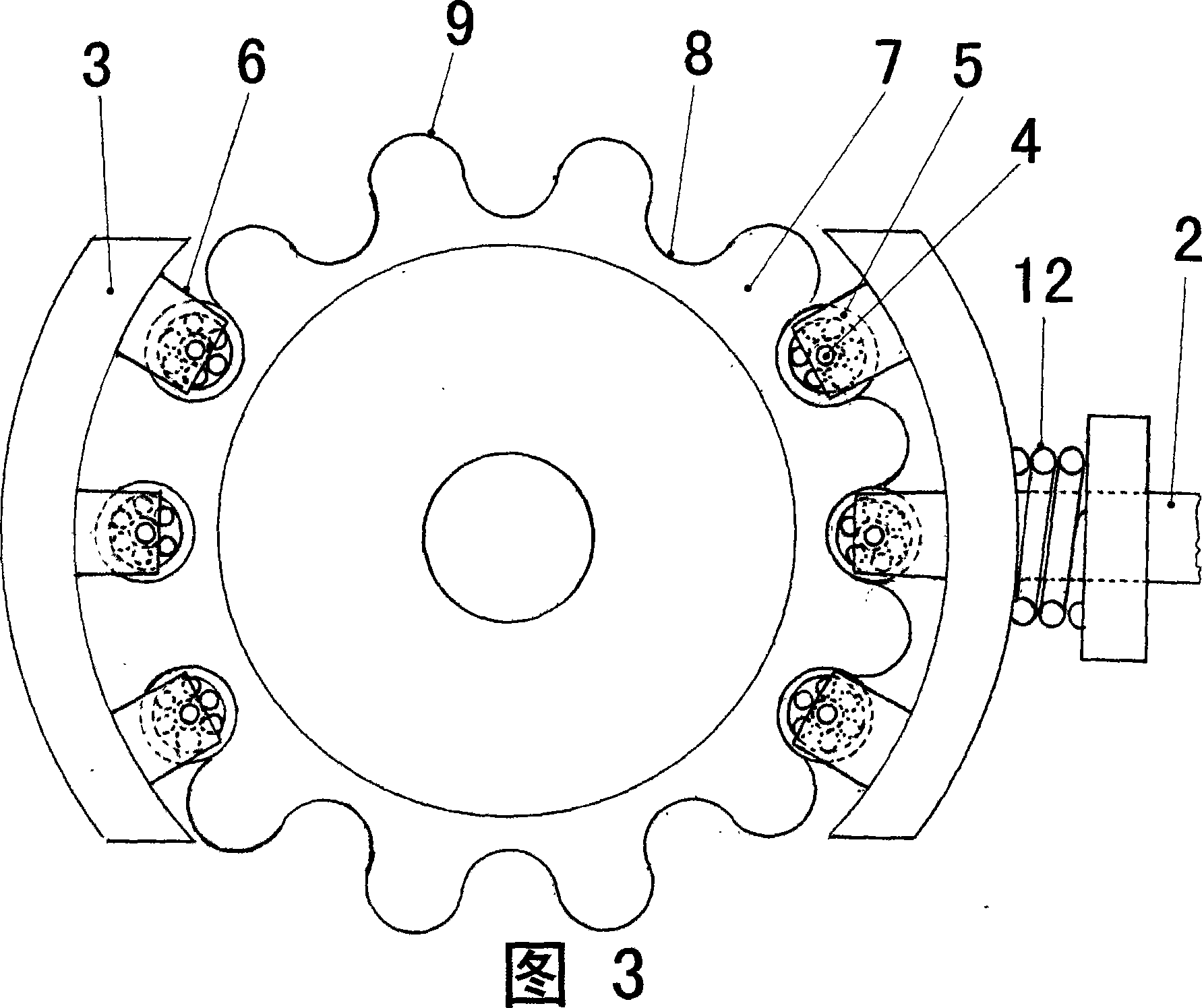

[0017] As shown in Figures 1 and 3, the braking device is composed of two separate working parts, the working surfaces of which are opposite. The working surface of the rotating part 7 has a concave surface 8 and a convex surface 9 arranged alternately. (rotating shaft is not drawn in the figure), the other work piece is fixed, and its working surface is equipped with a series of rollers 5 through the wheel frame 6, and the roller shaft 4 is equipped with rolling bearings, and is connected to the base 3 on the working surface One end of the push rod 2 in the telescopic press cylinder body 1, the pressure transmission medium in the cylinder body 1 can use hydraulic oil or compressed air, and the direction of the push rod 2 is coaxial with the rotating shaft of the rotating member 7. When braking, the push rod 2 presses the roller 5 to the concave surface 8 and the convex surface 9, and the friction force generated on the contact surface is very small, so there is little heat, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com