Main cable wrapping machine and wrapping method therefor

A wire winding machine and wire winding technology are applied to bridge parts, erection/assembly bridges, bridge forms, etc., which can solve the problems of incomplete functions and high prices, and achieve the effect of easy operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

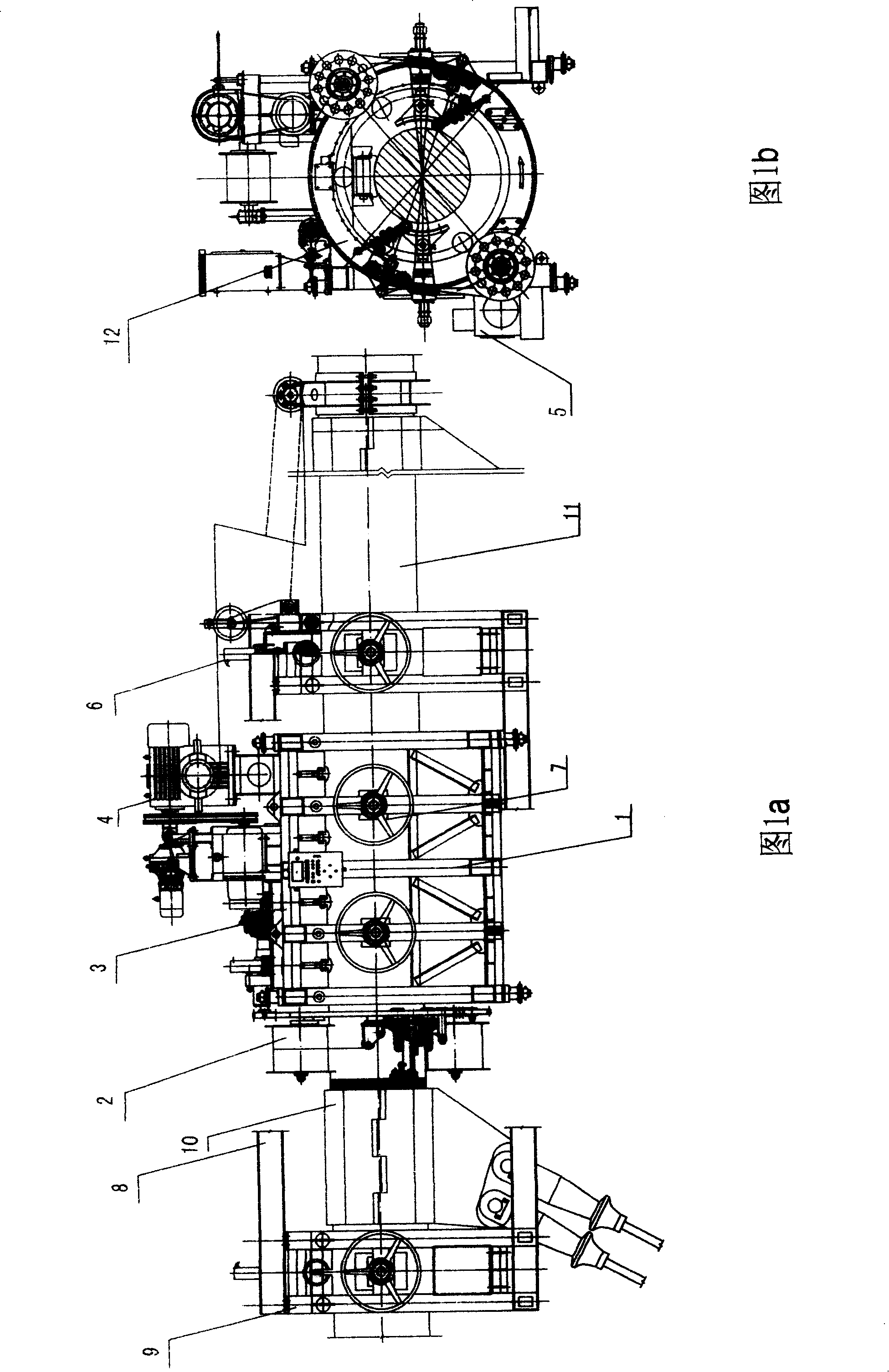

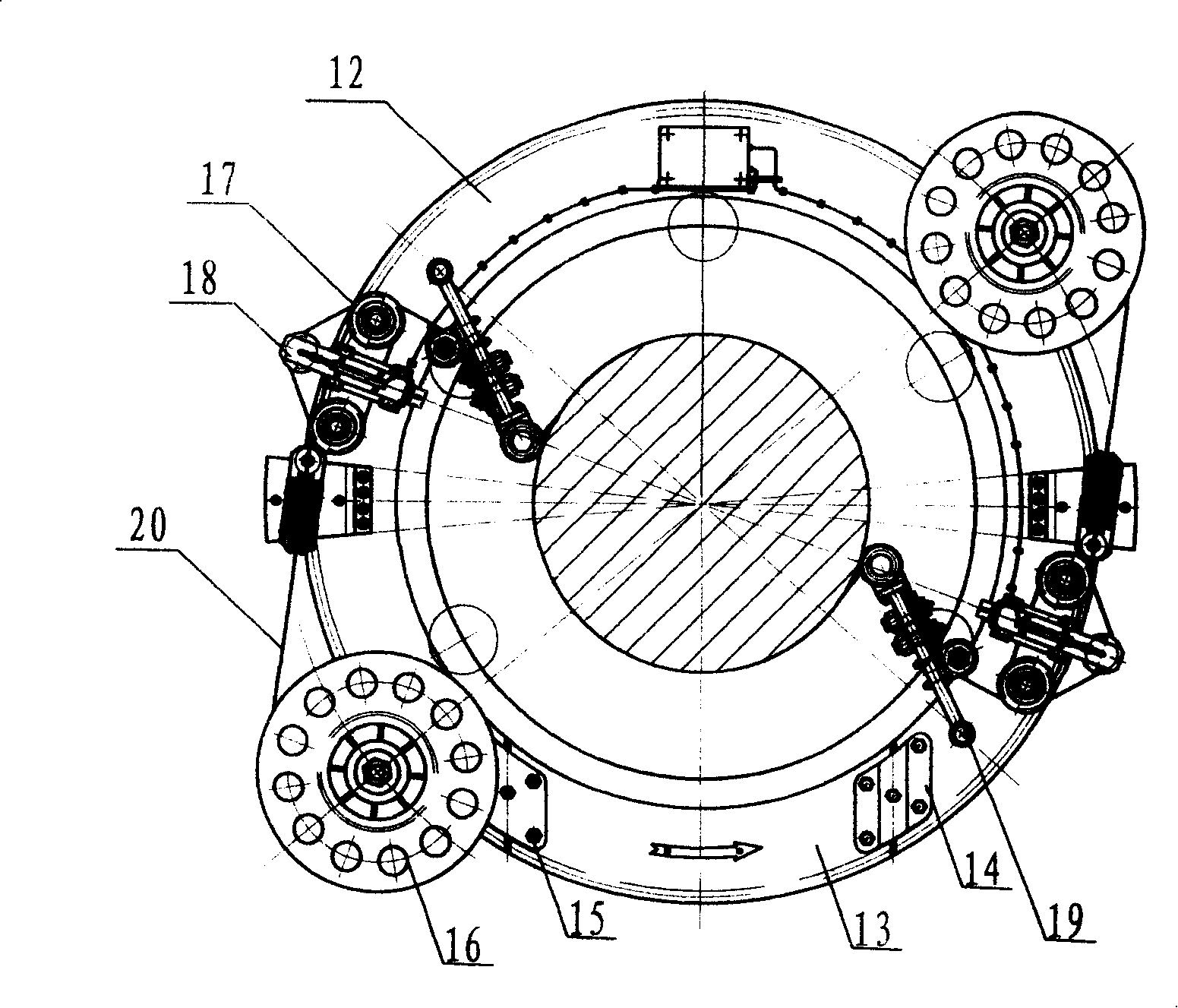

[0051] Referring to Figure 1a, b, the main wire winding machine is composed of four parts: the main machine, the front and rear clamping frames, and the guide beam.

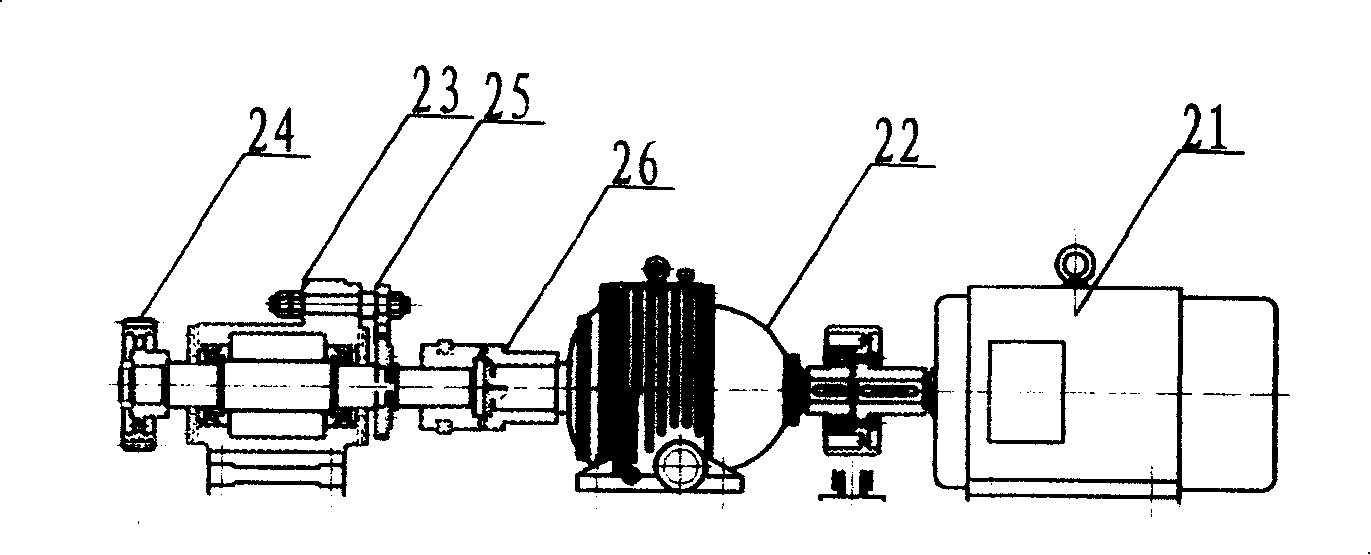

[0052] The functions and principles of each institution are described as follows:

[0053] (1) Main engine: The frame 1 of the main engine is a door-shaped lower opening frame, which is formed by tailor-welding of section steel and steel plate. On its crossbeam and front column, large ring gear rollers are installed; four sets of clamping mechanisms 7 are installed on its side columns; In order to reduce the center of gravity, a hydraulic pump station 5 and a tool box are installed below the frame both sides.

[0054] There is a tie rod under the column of the corresponding clamping point at the opening of the frame. When you want to clamp the main engine, you should install the tie bar first and then clamp the main engine on the main cable 11. After loosening the main engine clamping mechanism, you should remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com