Method for refining tanshinoneIIA sodium sulfonate

A refining method and sodium sulfonate technology are applied in the preparation of steroids, chemical instruments and methods, steroidal compounds, etc., which can solve the problems of large solvent usage, ineffective effect, and insufficient purity for injections, etc., and achieve low cost, The effect of simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

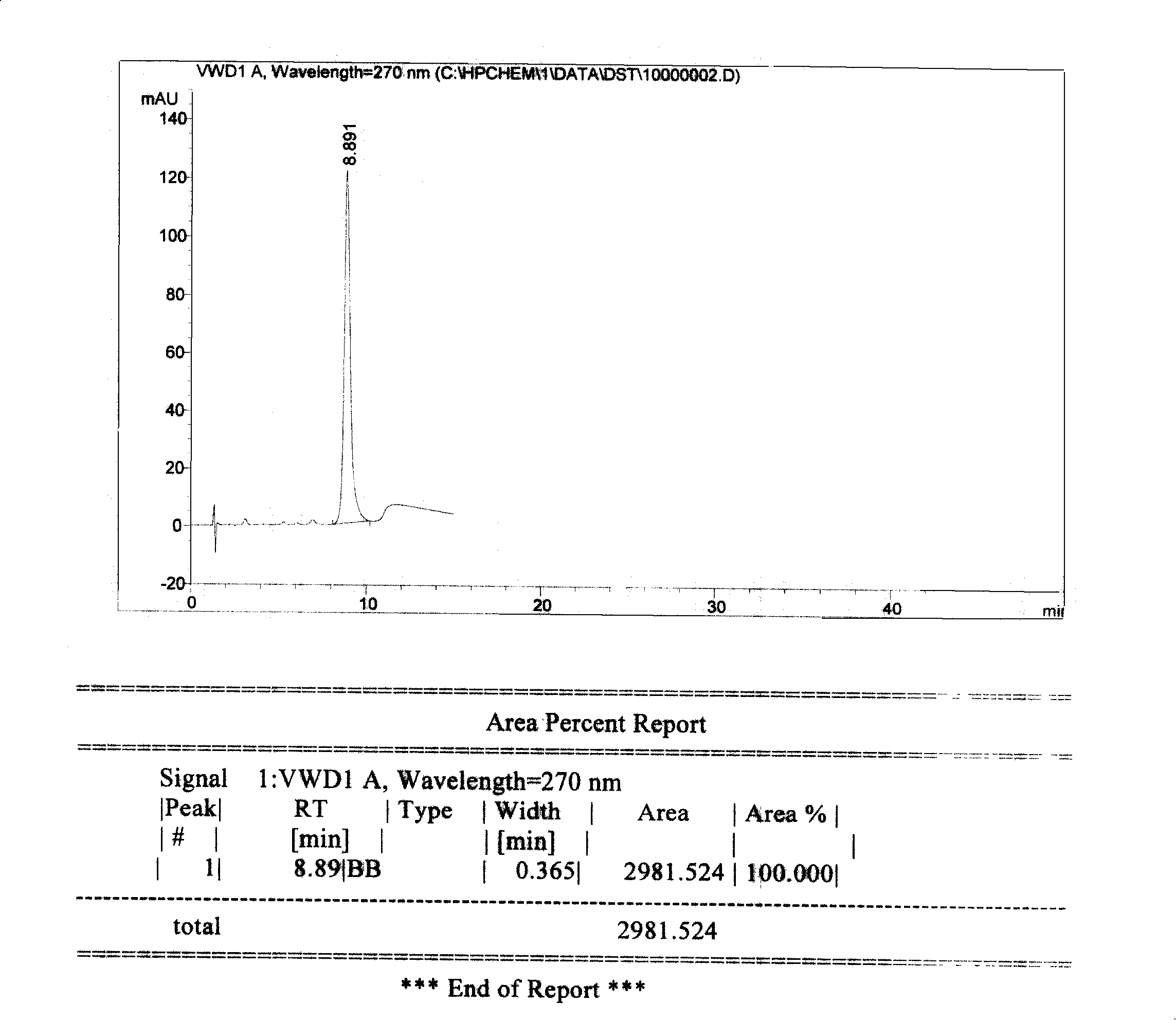

[0031] In a 100ml reaction bottle, add Tanshinone II A Sodium sulfonate crude product 1.0g (commercially available, HPLC method content 93.6%, m.p. = 234 ° C ~ 235 ° C, see attached Figure 1 ,), suspended in a mixed solvent consisting of 7ml of deionized water, 1ml of acetone and 6ml of absolute ethanol, fully stirred, the temperature of the water bath was raised to 50°C to 55°C until all the samples were dissolved, hot filtered, the filter residue was discarded, and the filtrate was slowly cooled to 5 ℃, crystallize for 4 hours, filter, and place the filter cake in a vacuum drying oven A Sodium sulfonate pure product 0.8g, m.p. = 239 ℃ ~ 240 ℃ (measured by X-4 micro melting point apparatus, Shanghai Precision Scientific Instrument Co., Ltd.), the yield is 80.0%, and the content is 100.1% based on dry product.

Embodiment 2

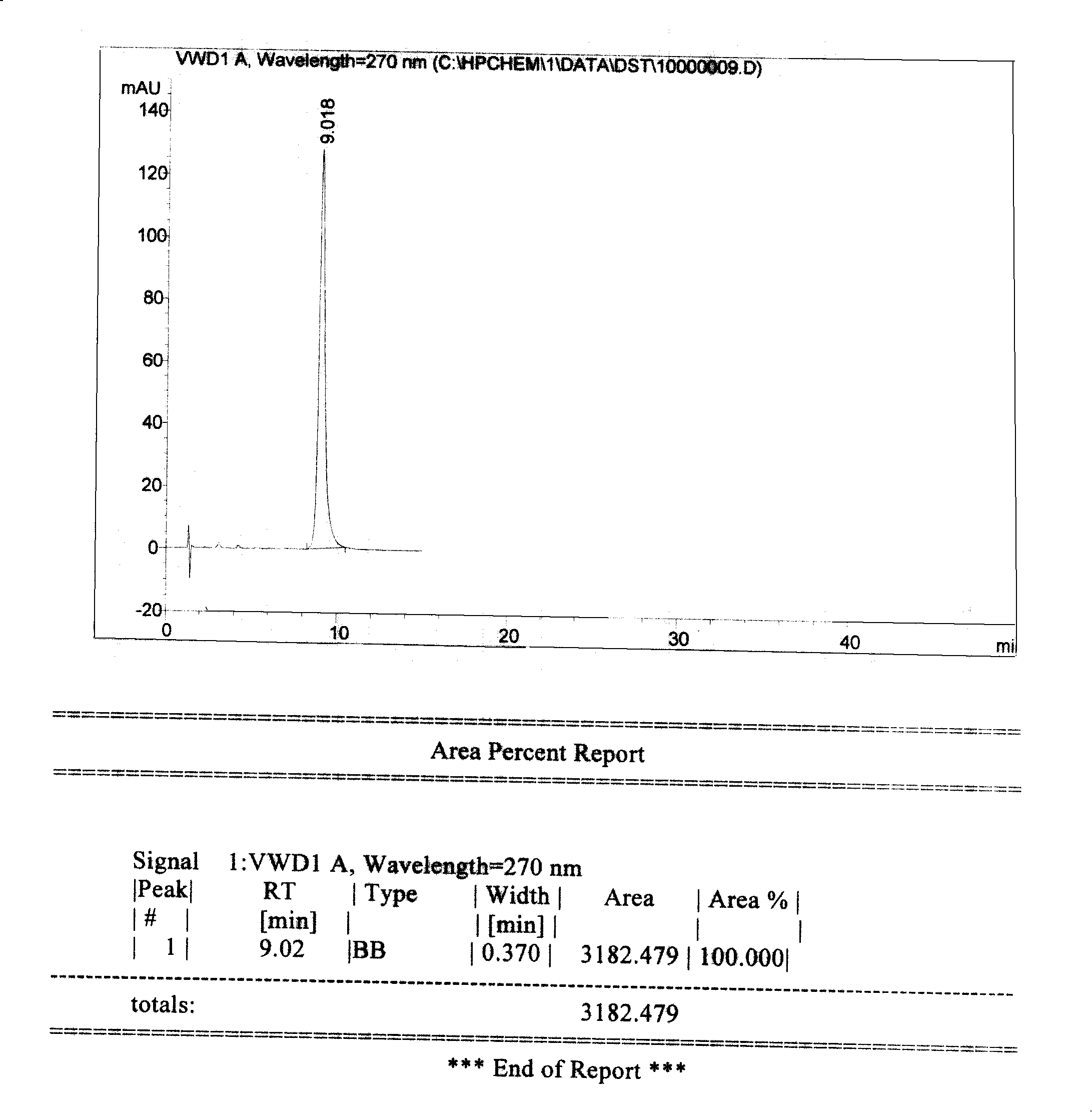

[0033] In a 250ml reaction bottle, add Tanshinone II A Sodium sulfonate crude product 16.0g (same as Example 1), is suspended in the mixed solvent that 80ml deionized water and 80ml acetone form, fully stirs, and water bath is warmed up to 50 ℃~55 ℃ to sample all dissolvings, heat filtration, discard filter residue, Slowly lower the temperature of the filtrate to 0°C, crystallize for 4 hours, filter, and place the filter cake in a vacuum drying oven A 12.9g of pure sodium sulfonate, m.p.=238°C-240°C, yield 80.6%, content of dry product is 99.9%.

Embodiment 3

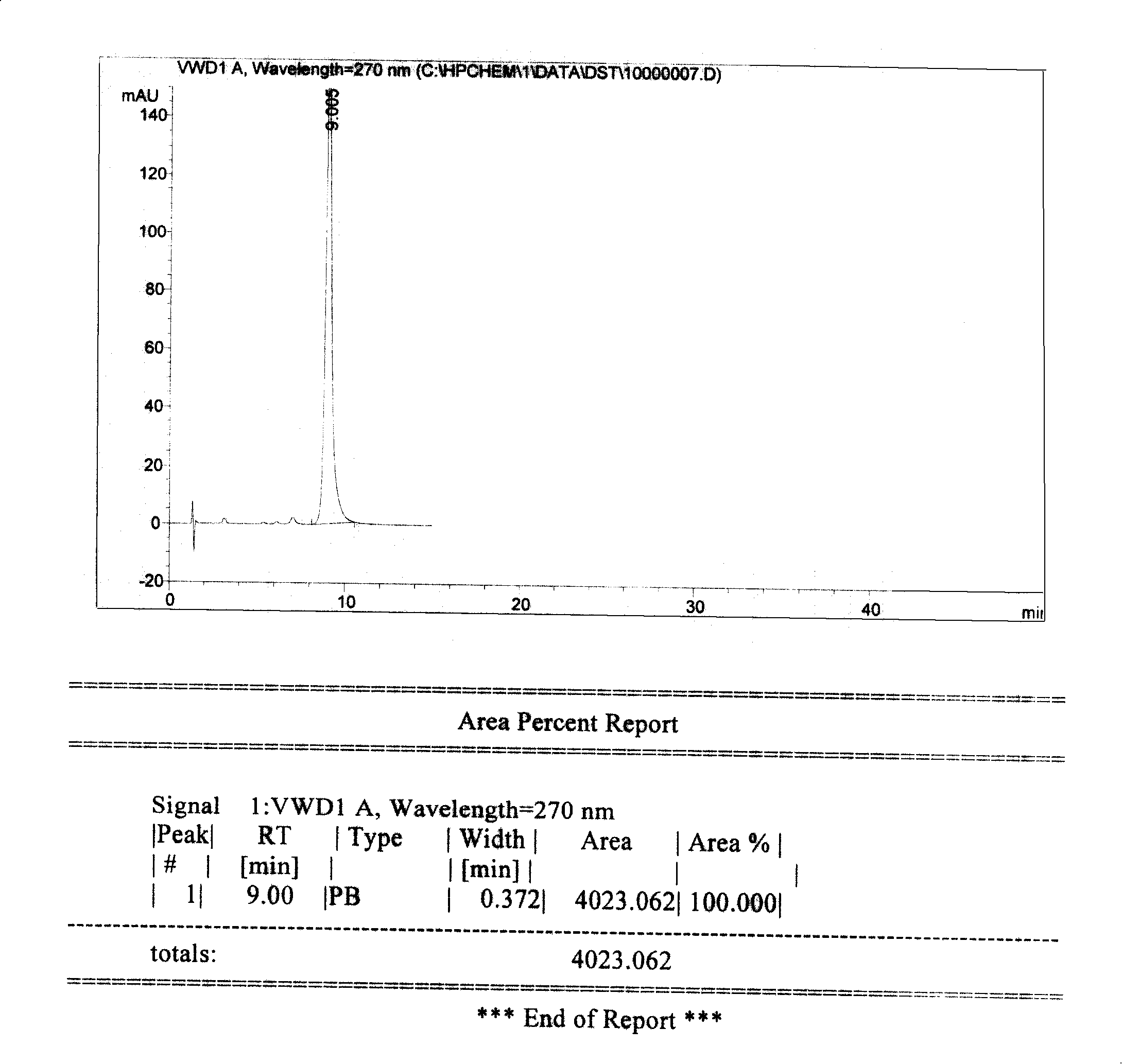

[0035] In a 250ml reaction bottle, add Tanshinone II A Sodium sulfonate crude product 16.0g (same as Example 1), is suspended in the mixed solvent that 80ml deionized water and 80ml acetone form, fully stirs, and water bath is warmed up to 40 ℃~45 ℃ to all dissolving of sample, heat filtration, discard filter residue, The filtrate was slowly cooled to 30°C, crystallized for 4 hours, filtered, and the filter cake was fully washed with about 10ml of iced deionized water, drained and placed in a stainless steel shallow tray for freeze-drying (-40°C-35°C, 30- 36h), namely Tanshinone II A Sodium sulfonate pure product 12.7g, m.p.=239 ℃~240 ℃ (same as embodiment 1), yield 63.4%, content is 101.3% with dry product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com