Steering adjustment screw retainer

A technology of bolts and retaining pieces, applied in the field of adjustment structures, which can solve problems such as not allowing rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

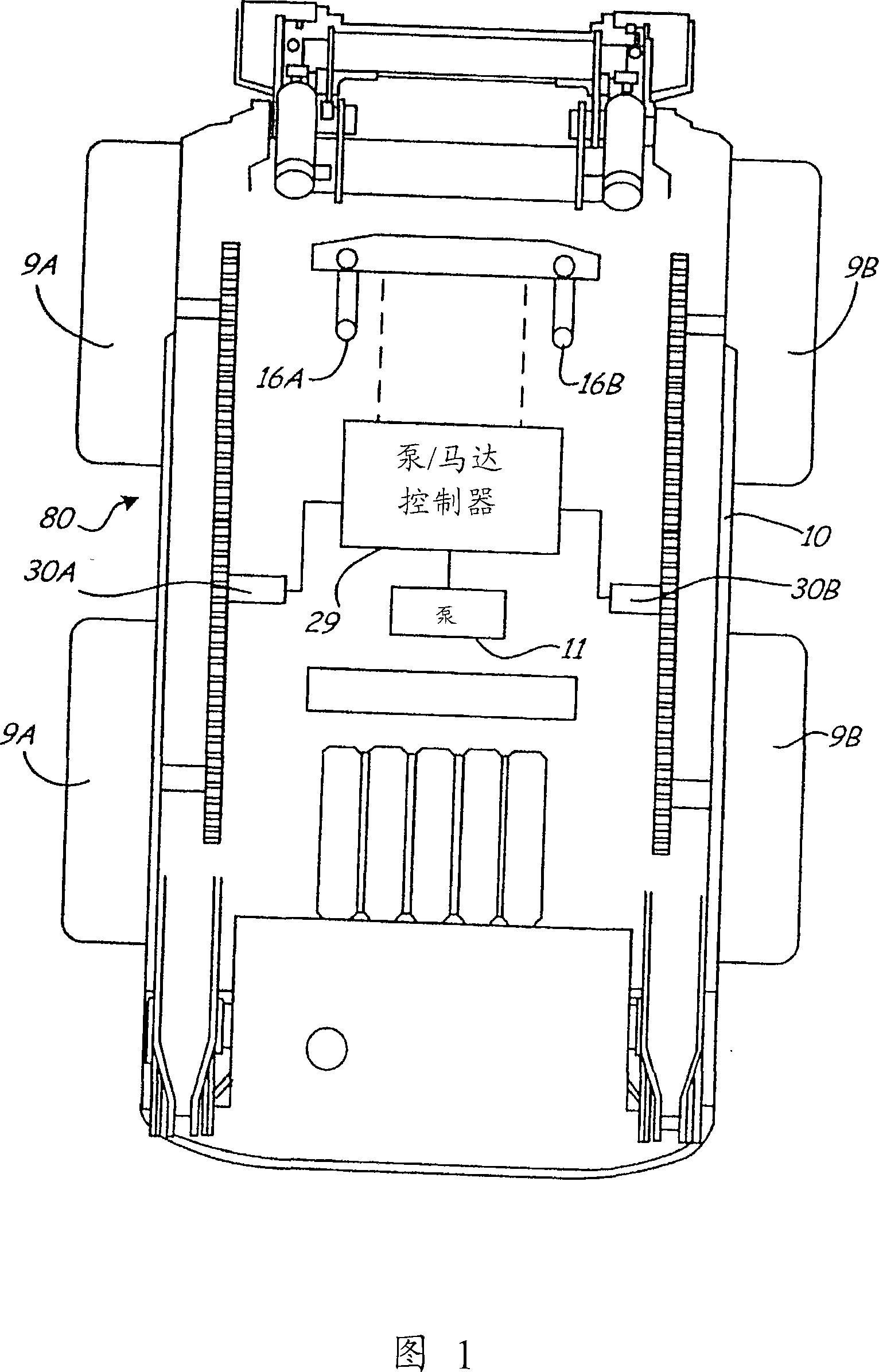

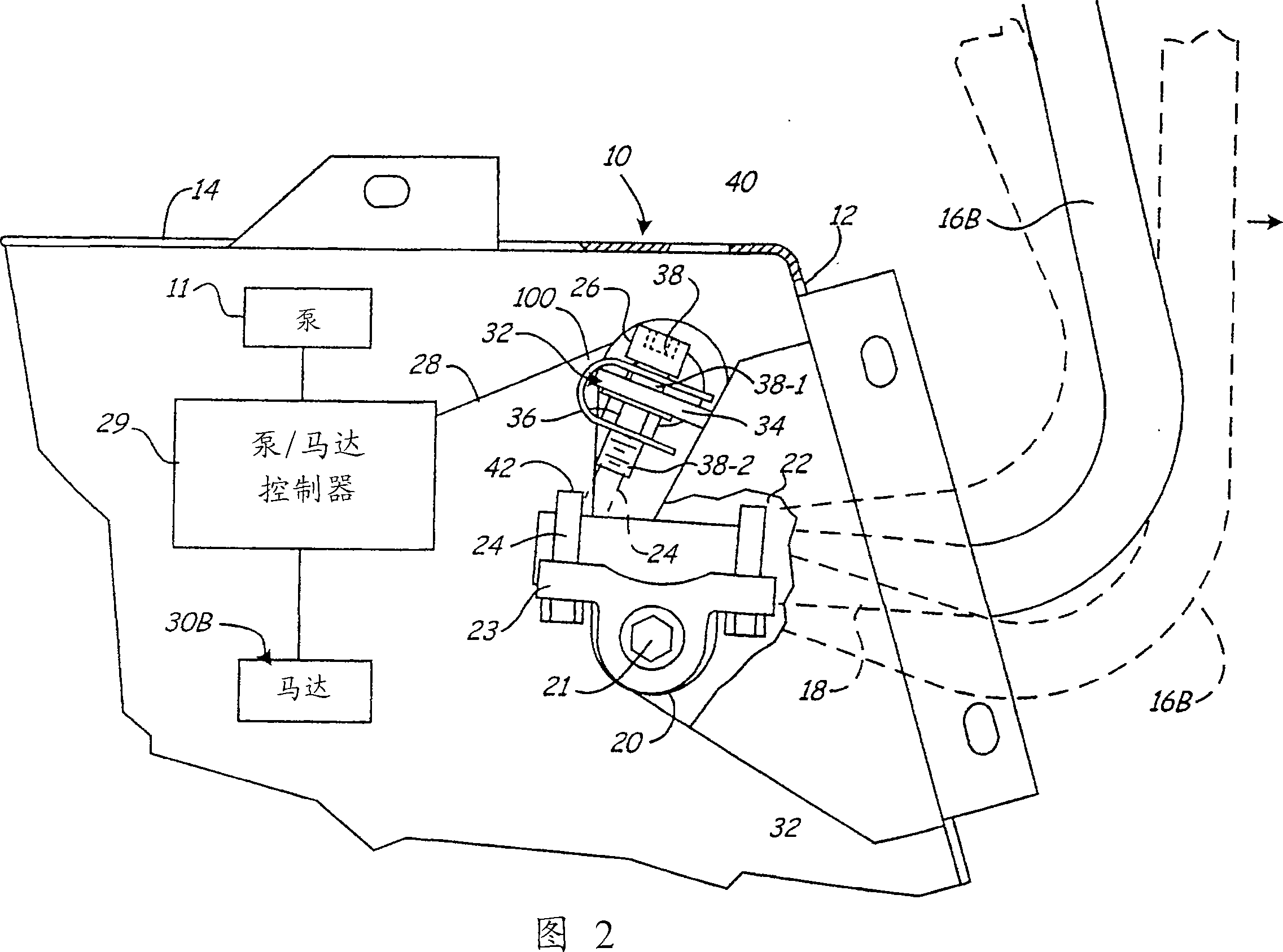

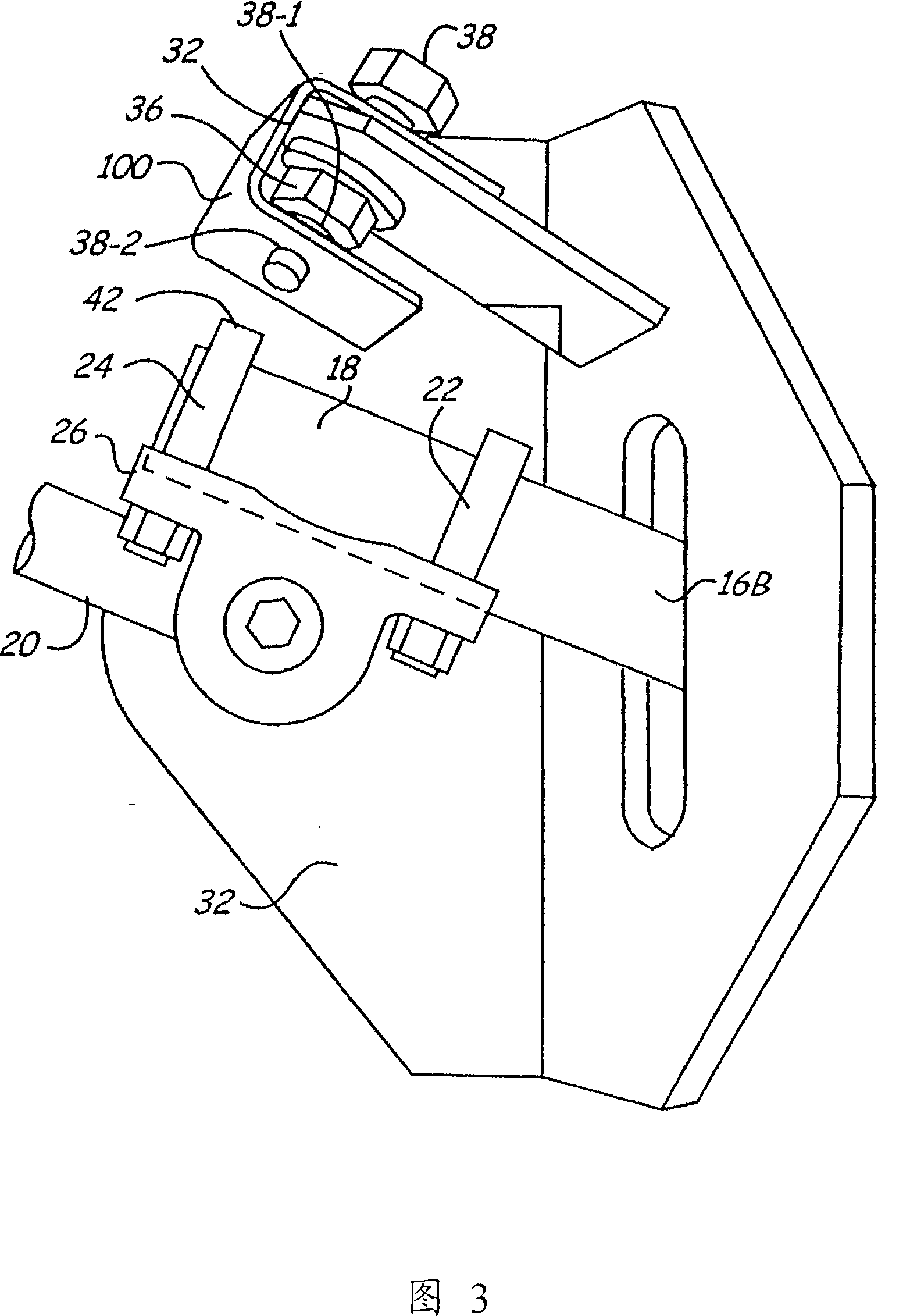

[0014] The use of a pair of control levers to control the movement of skid and turn loaders is known. Figures 1 and 2 respectively depict a skid steer vehicle including a loader 80 as shown and described, having wheels driven in pairs and comprising a pair of left wheels 9A and a pair of right wheels 9B. The loader 80 has a frame 10 supporting an engine that powers a pump 11 to provide pressurized fluid to a controllable drive motor and other components.

[0015] Drive control levers or rods 16A, 16B are rotatably mounted on shafts under the operator or cab platform 12 and extend into the cab. Each side of the loader is driven by separate controlled flow and variable speed (swash plate) motors 30A, 30B. The speed of the motors 30A, 30B depends on the position of the respective steering rod. As can be seen in the figure, the motor 30A simultaneously drives the two wheels 9A, and the motor 30B simultaneously drives the two wheels 9B.

[0016] In the intermediate position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com