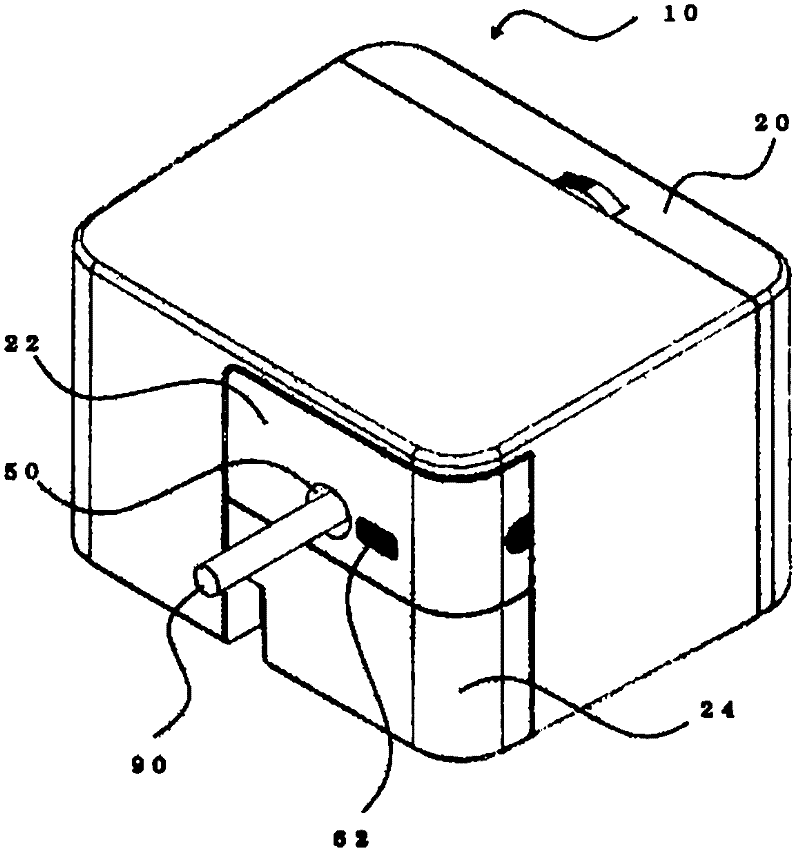

Electric pencil cutter

A technology for cutters and pencils, which can be used in sharpening devices, printing, office supplies, etc., and can solve problems such as insufficient safety devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

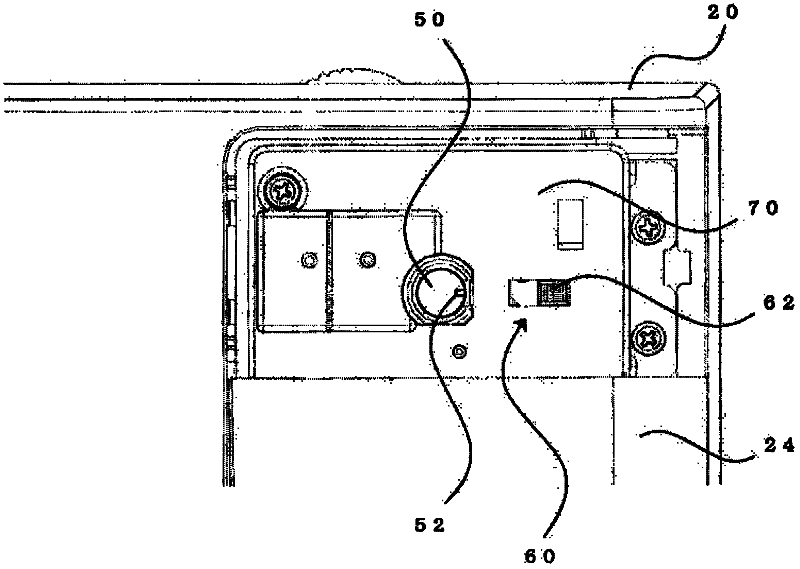

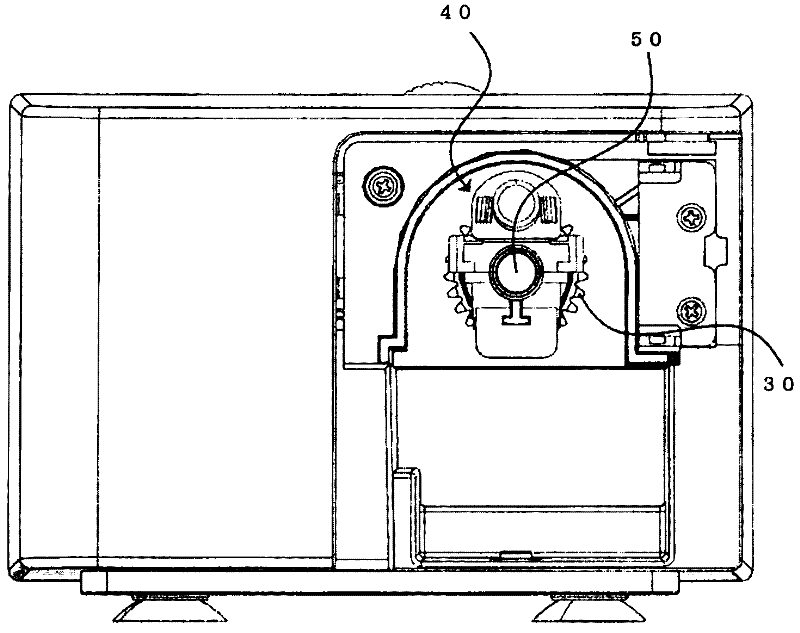

Embodiment 1

[0053] Both Embodiment 1 and Embodiment 2 can be implemented selectively without any limitation. That is, while the movable protrusion 52 provided in the insertion hole 50 is operated from the outside of the insertion hole 50 to move the movable protrusion 52, the removal mechanism 60 using the operation switch 62 can also be provided. 42 The cutting mechanism 40 is detachably attached to the removal mechanism 60 of the main body 20 of the electric pencil cutter 10 . Thus, even in the state where the driving mechanism in which the movable protrusion 52 of the actuating switch protrudes into the insertion hole is stopped, the residue remaining inside the cutting mechanism because it cannot be taken out can be easily removed, and since it can be easily It is easy to disassemble the cutting mechanism 40 from the main body 20 of the electric pencil sharpener 10 to remove and reassemble the residue remaining inside the cutting mechanism because it cannot be taken out, so it is poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com