Loading base arrangement

A technology of bottom plate and locking device, which is applied to vehicles with easy-to-detachable loading components, transportation and packaging, detachable/non-detachable seats, etc., and can solve problems such as multi-space, space obstruction, and height restrictions on loading volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

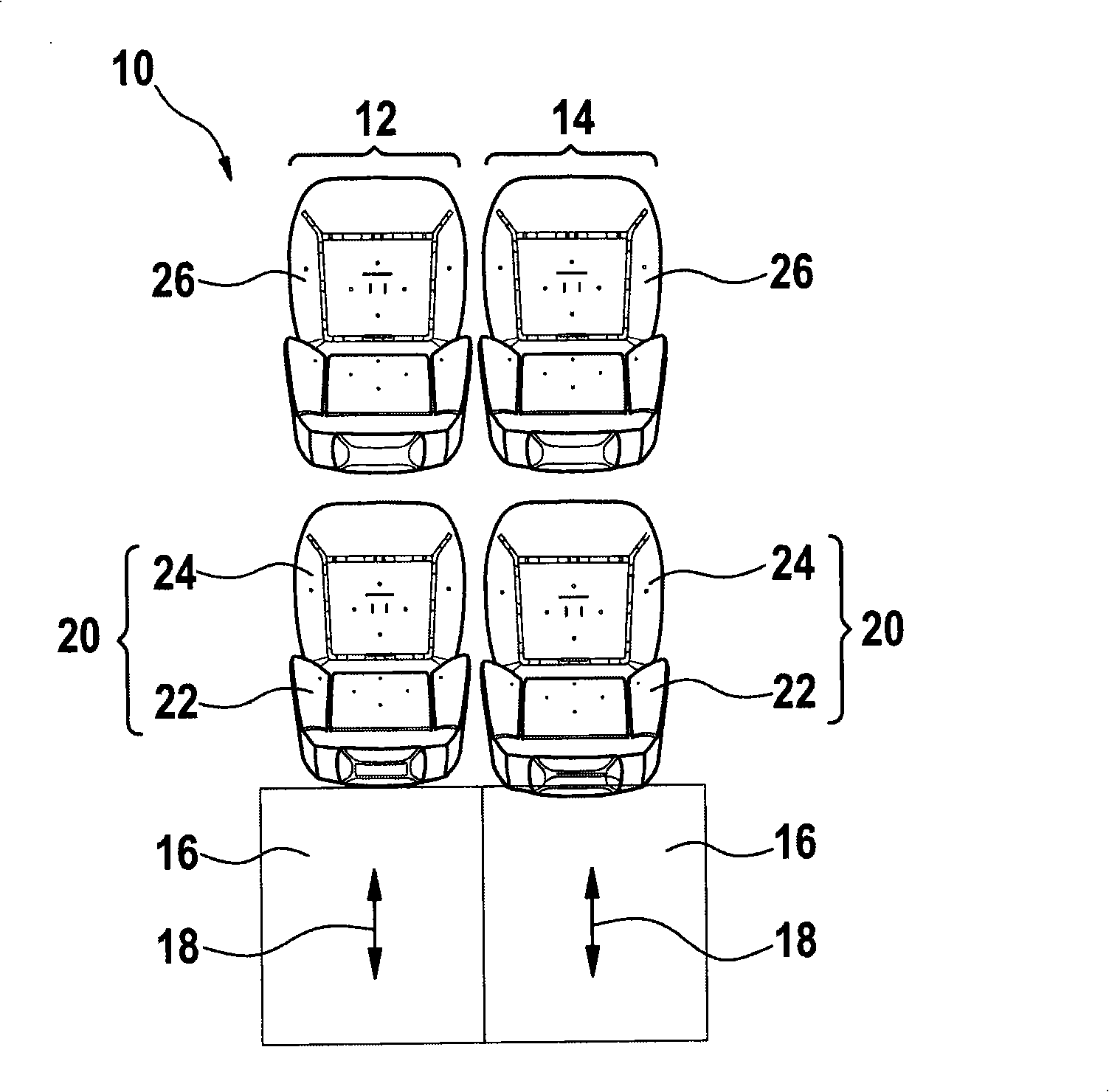

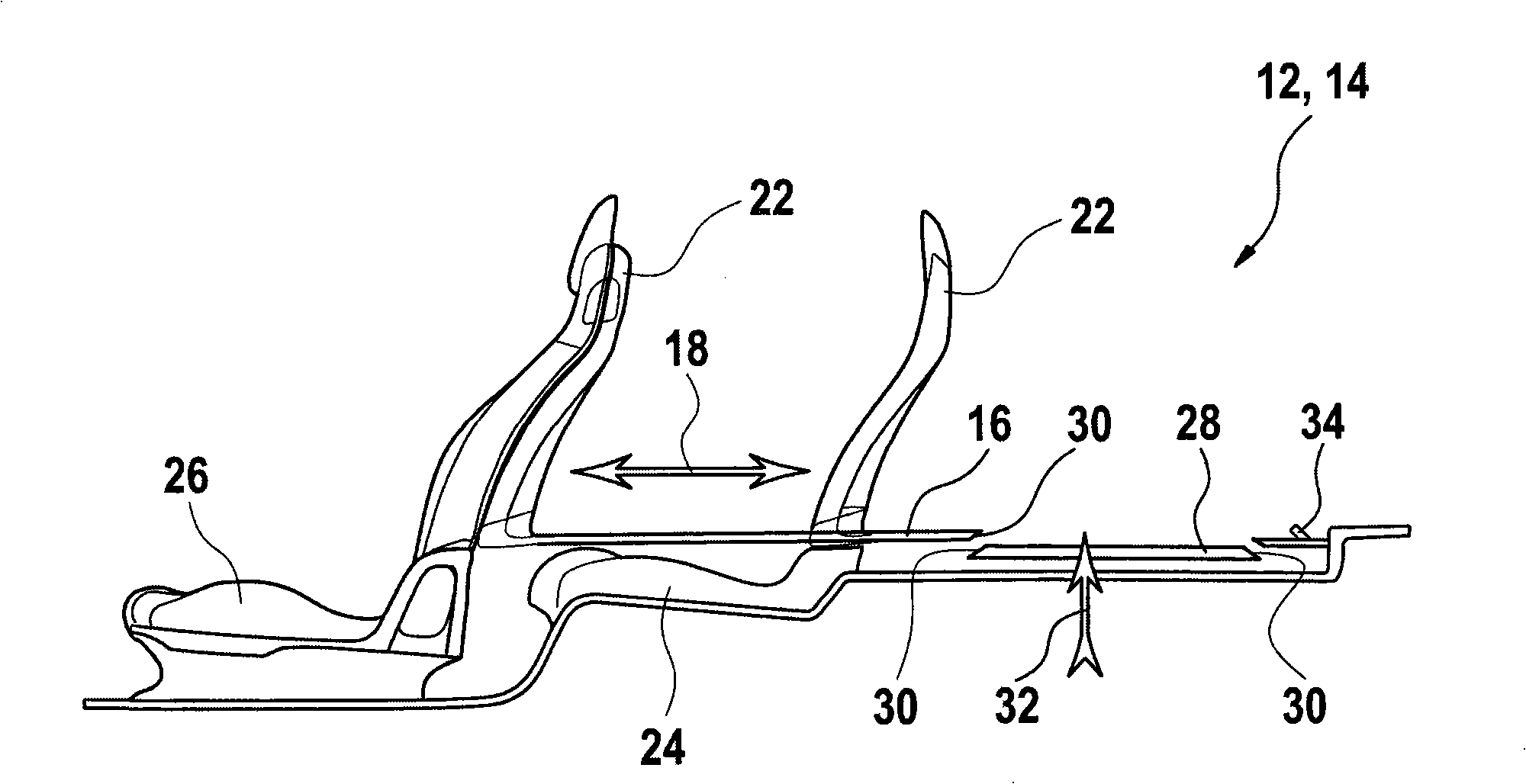

[0022] exist figure 1 In the vehicle interior 10 shown, a first loading floor structure 12 and a second loading floor structure 14 are arranged. The first load floor structure 12 is arranged on the driver's side, and the second load floor structure 14 is arranged on the passenger side. The loading floor structures 12 , 14 each have a floor element 16 movable in the direction of travel, which is displaceable in the direction of the arrow 18 . In each case a rear seat 20 is arranged in front of the floor element 16 , which has a backrest 22 and a seat cushion 24 .

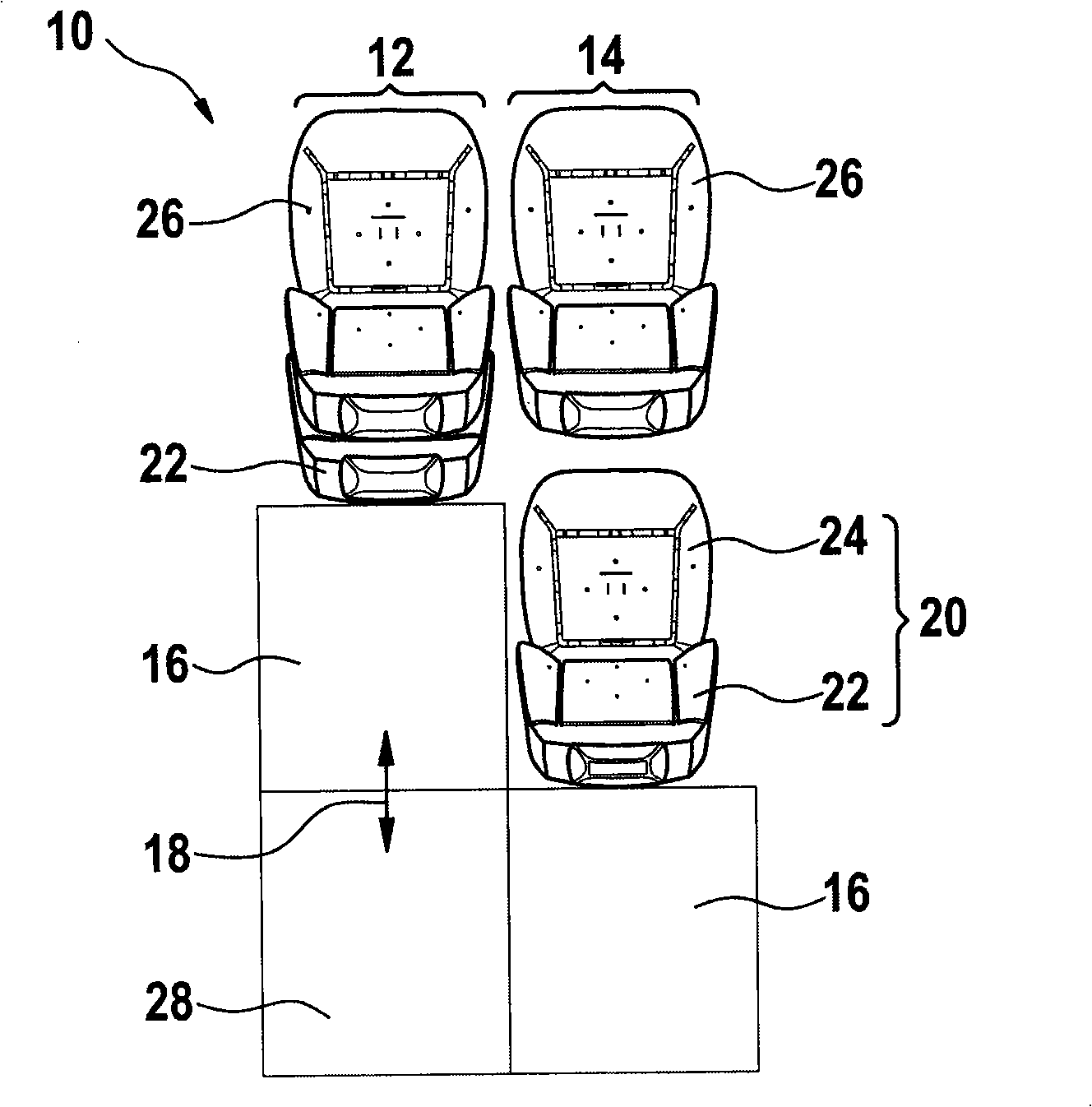

[0023] The backrest 22 is connected to the floor element 16 so that the backrest 22 moves together with the floor element 16 when the floor element 16 moves in the direction of the arrow 18 . exist figure 2 In the case of the loading floor structure 12 shown in the fully extended state, the floor element 16 is drawn out so far that the backrest 22 lies against the front seat 26 . An additional floor 28 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com