Twisted bar heilical spring compound suspension frame device

A suspension device, coil spring technology, applied in the direction of elastic suspension, suspension, transportation and packaging, etc., can solve the problem that the off-road ability cannot meet the high mobility requirements, reduce the reliability of the suspension system and even the whole vehicle, suspension coil spring Increased processing costs and other issues to achieve the effect of overcoming the difficulty of processing, improving driving safety, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

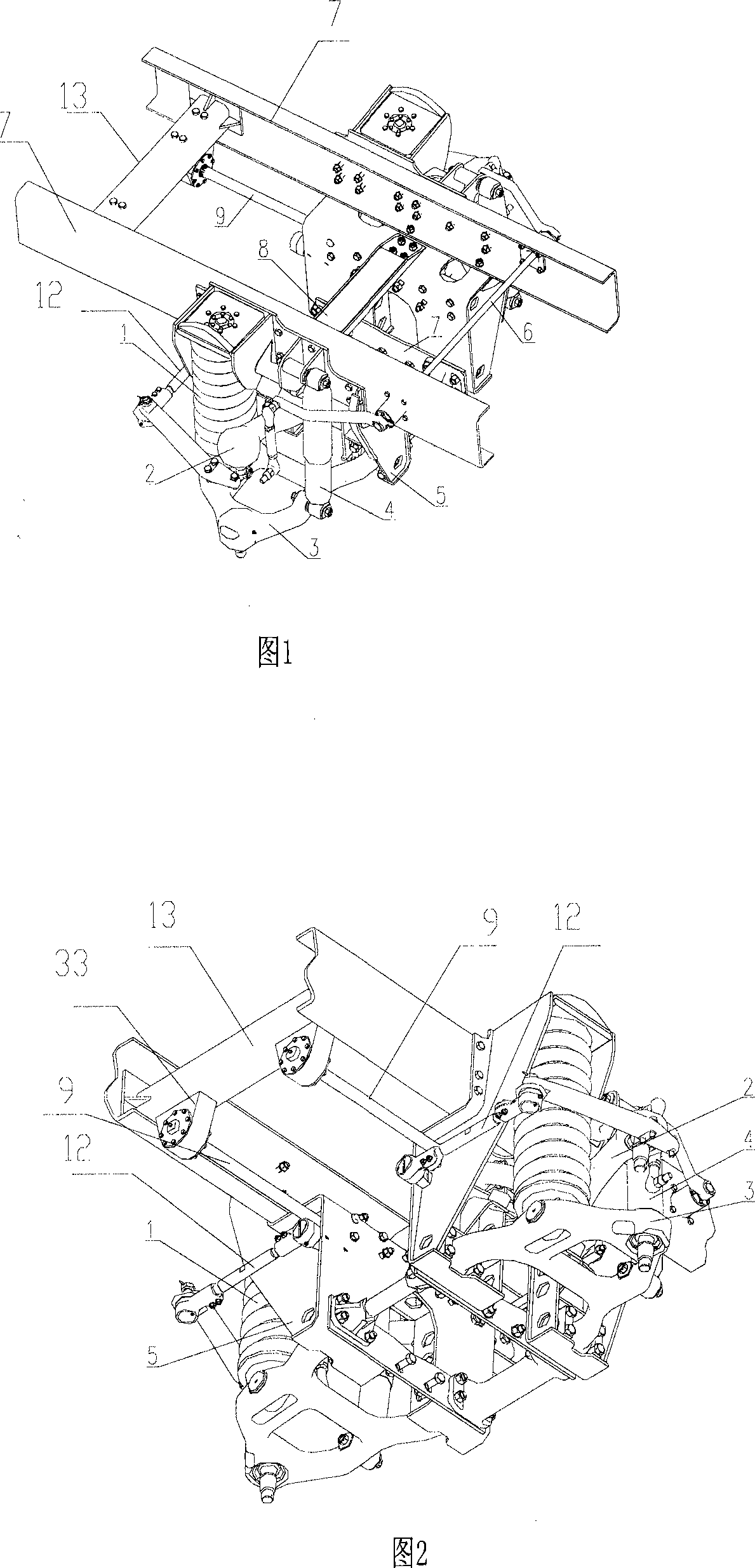

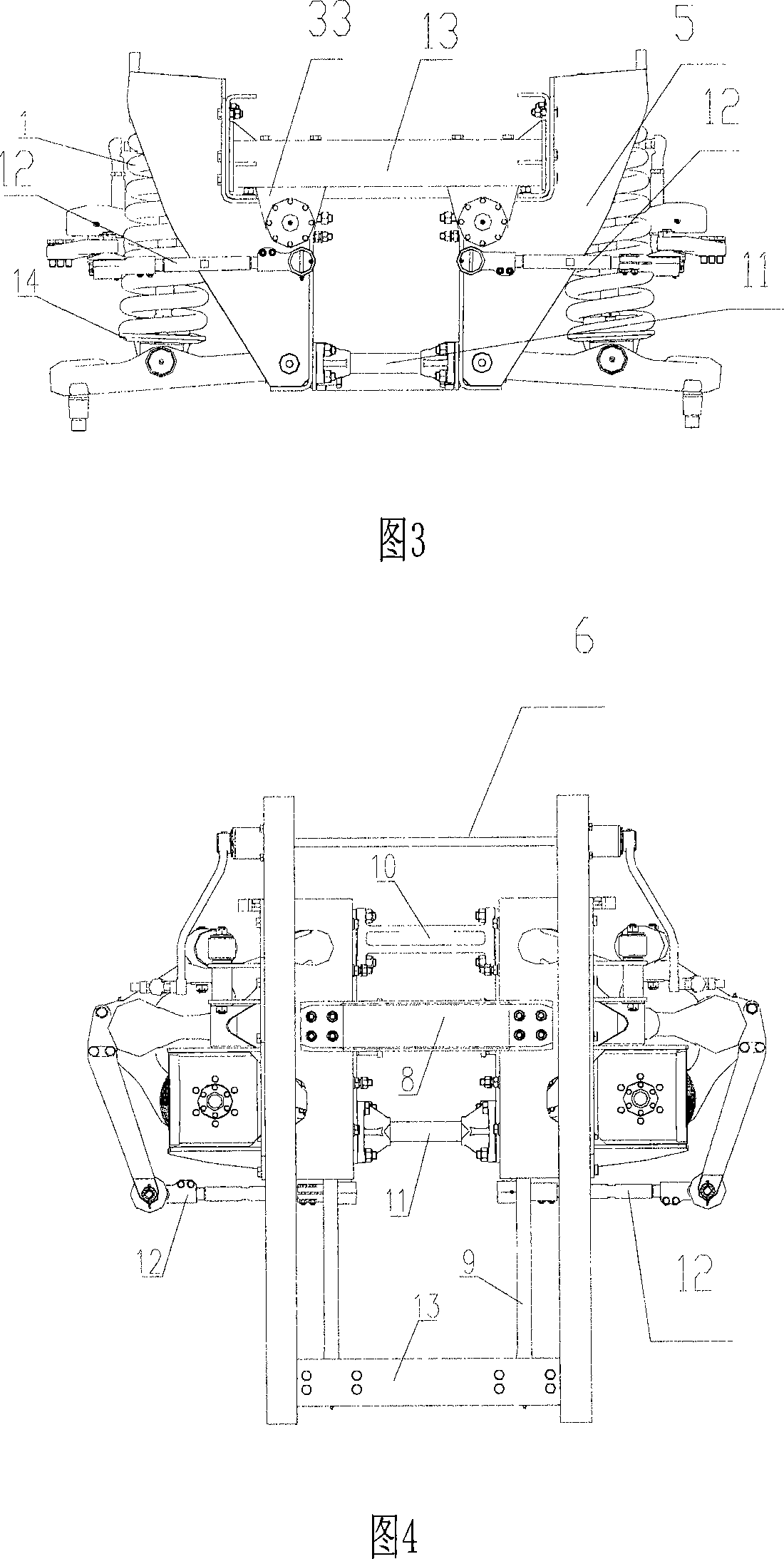

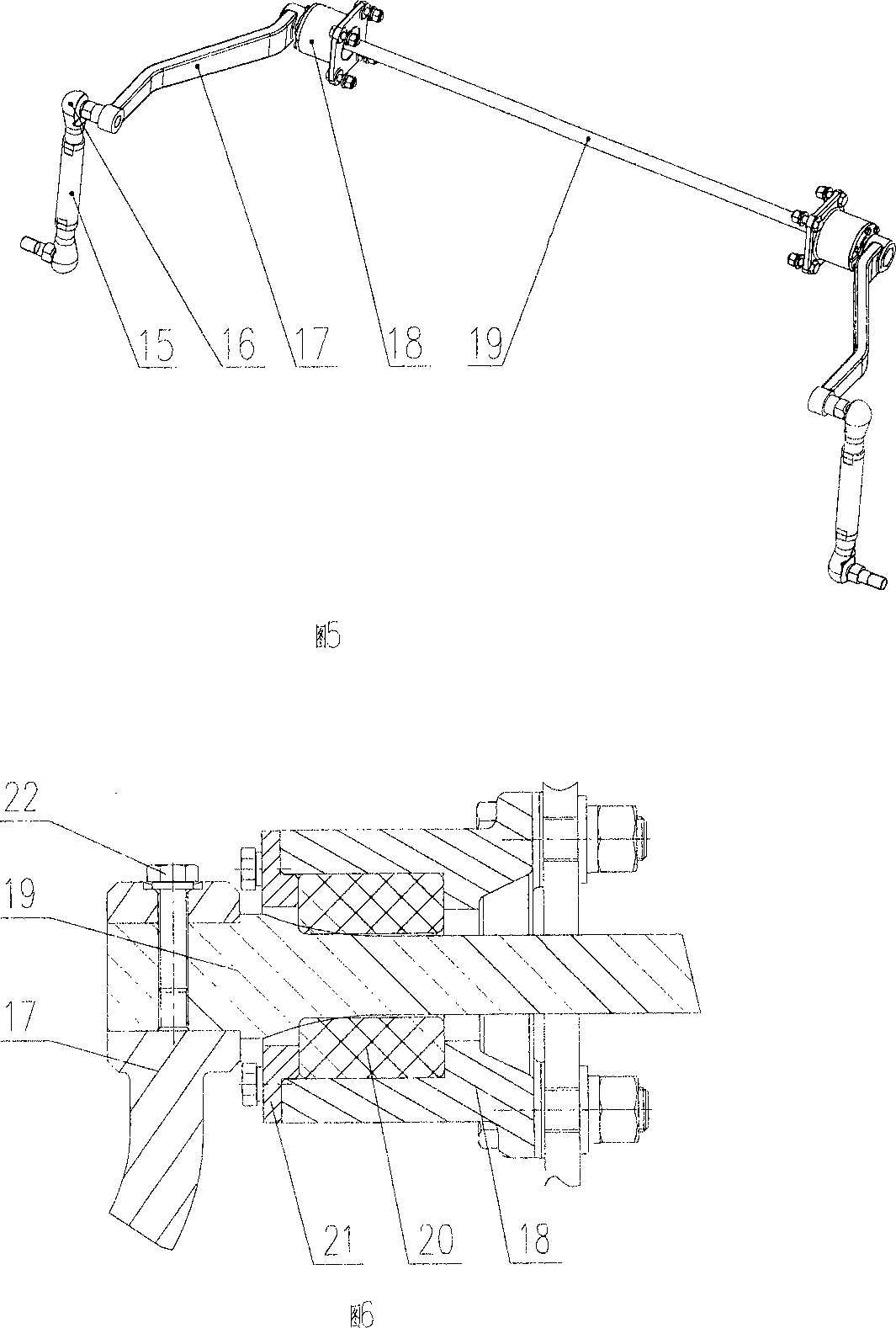

[0024] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and at the same time, the advantages of the present invention will become clearer and easier to understand.

[0025] The present invention adopts the torsion bar coil spring independent suspension device and adopts the double wishbone independent suspension structure (as shown in Fig. 1-Fig. 4), and the main elastic part adopts a large stroke linear (or variable rigidity) coil spring 1, and the secondary elastic part adopts a torsion bar Spring 9, when the torsion bar spring 9 is involved in the work, the stiffness of the suspension is further changed to adapt to the needs of the vehicle.

[0026] The coil spring 1 is installed on the lower suspension arm 3 of the guide mechanism, and the double-acting cylindrical shock absorber 4 is installed on the other side of the lower suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com