Bearing of a breaking device tool

A crushing device and tool technology, applied in the field of tool bushings, can solve problems such as the difficulty of replacing bearing bushes, and achieve the effects of low manufacturing costs, shortened use interruptions, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

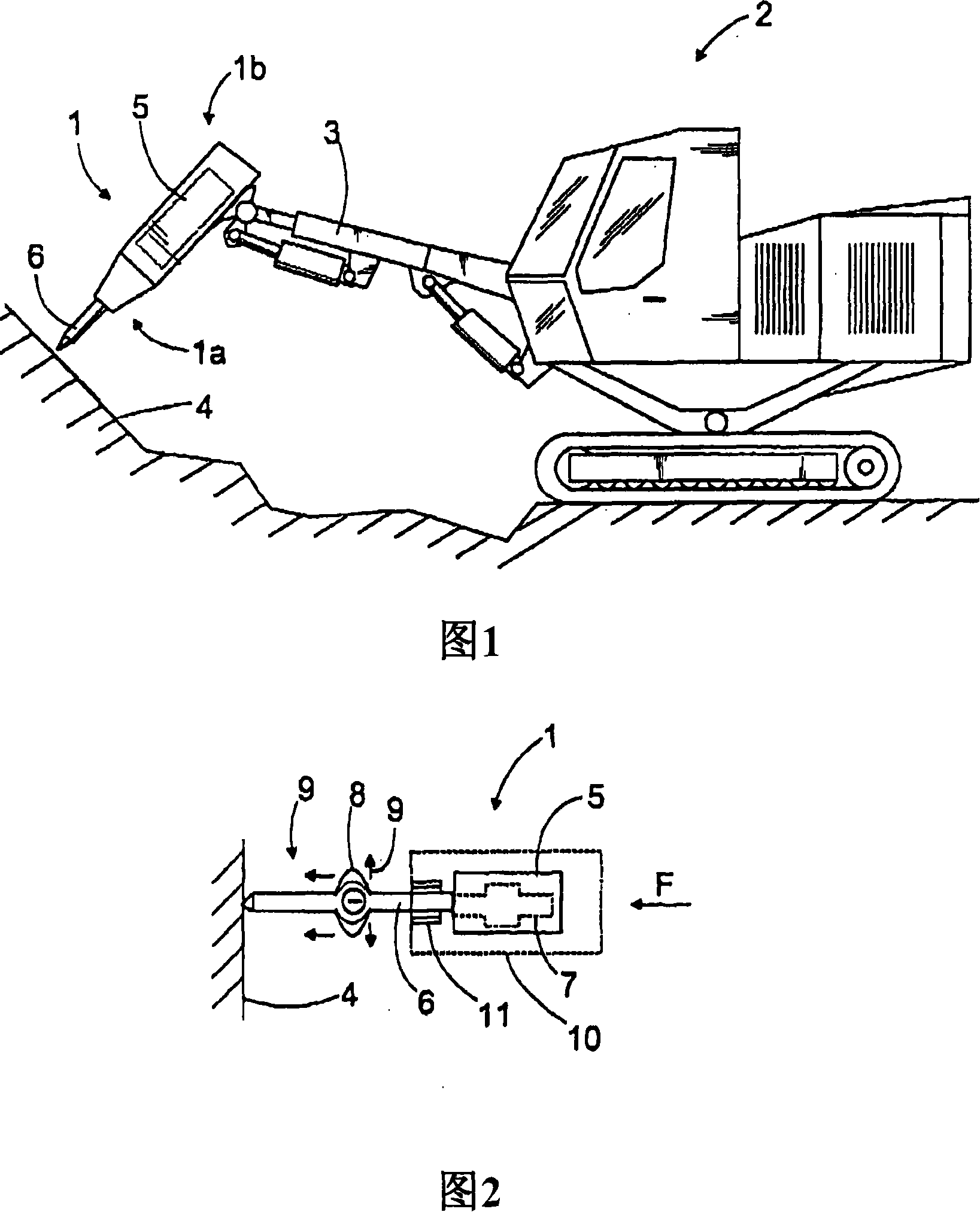

[0031] In FIG. 1 , a breaker 1 is arranged on a boom 3 in an excavator 2 . The breaker 1 can be a hydraulic, pneumatic or electric device. The crushing device 1 is pressed by the boom 3 on the material 4 to be crushed, at the same time a compressive stress pulse can be provided to a tool 6 connected to the hammer by means of an impact device 5 in the hammer and this tool 6 transmits this stress pulse to the material to be crushed. broken material. The impact device 5 generally comprises a reciprocating impact piston which impacts the impact surface of the upper end of the tool 6 . In some cases, the percussion element may be an element other than a reciprocating percussion piston. Furthermore, there may be a protective casing around the breaker 1, protecting the breaker from damage and contamination.

[0032] It may be noted that in this application the lower part 1a of the hammer refers to the end on the side of the tool 6, while the upper part 1b of the hammer refers to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com