Holothurian compound nutrition foods and production method thereof

A technology of nutritious food and sea cucumber, applied in food preparation, food science, application, etc., can solve the problems of high price, single performance, low output, etc., and achieve the effect of enhancing the body's resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

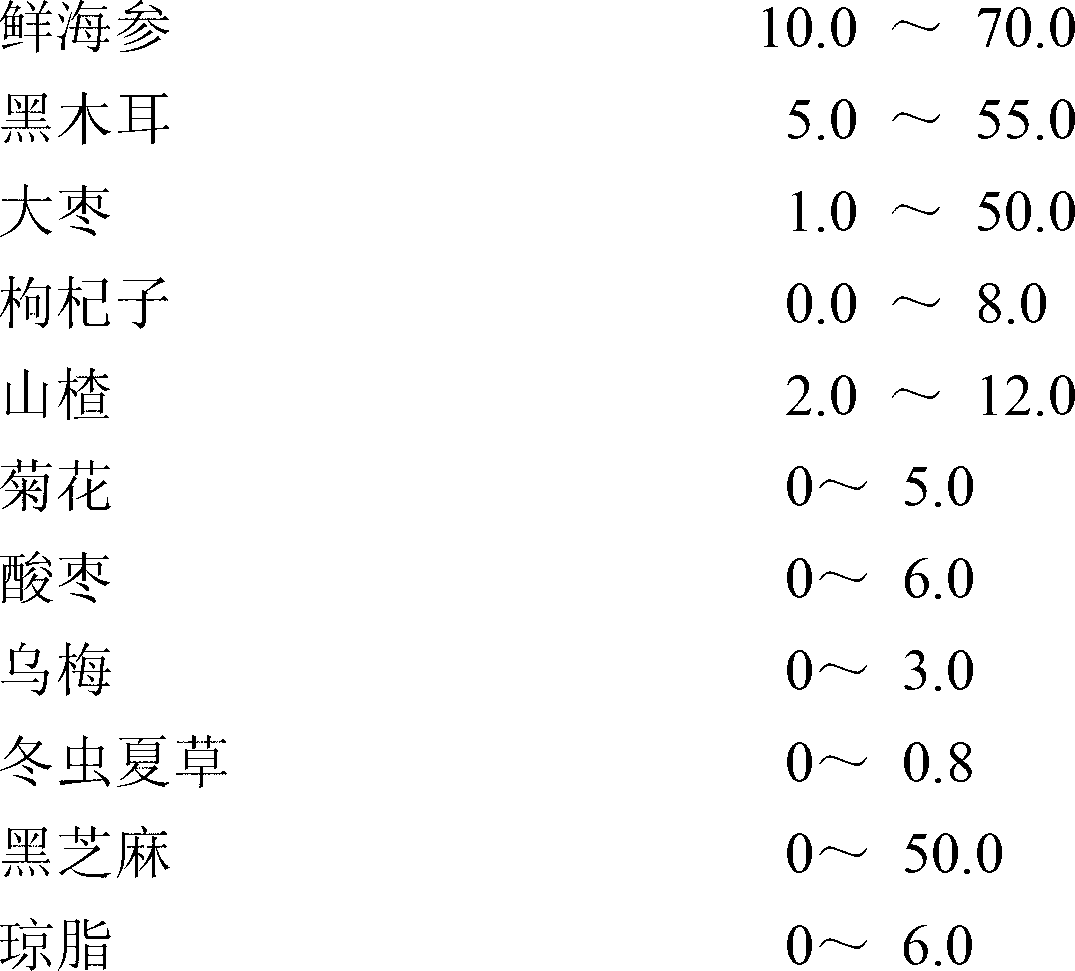

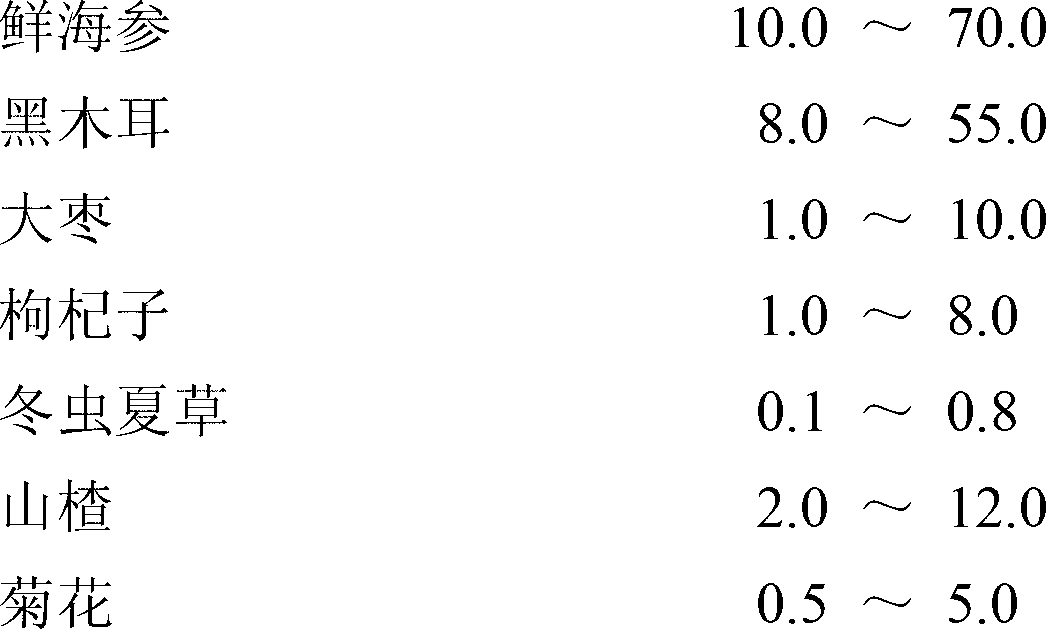

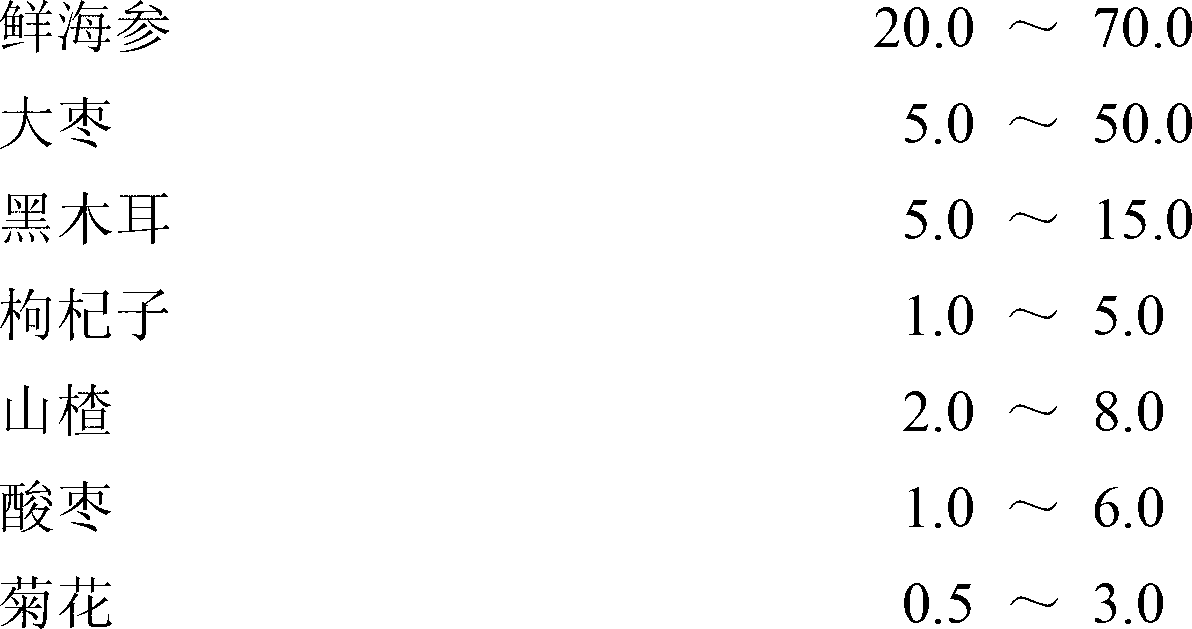

Method used

Image

Examples

Embodiment 1

[0091] Embodiment one: 1. get 13.5kg of fresh sea cucumbers after removing the intestines, add 14kg of ice water and homogenate, the homogenate should be careful, so that the sea cucumber particles are less than 0.5cm. Take the entire homogenate, add 90kg of water, and use trypsin for enzymolysis, the amount of enzyme added is 0.45kg, the enzymolysis temperature is 50°C, the enzymolysis time is 5h, the enzyme is inactivated at 100°C for 10min, and the enzymolysis process is properly stirred. The sea cucumber enzymatic hydrolyzate is centrifuged, and the supernatant is the sea cucumber extract. Activated carbon is used to decolorize and deodorize the extract. 2. The sea cucumber extract is heated and concentrated to 15kg. 3. Take 40.5kg of dried black fungus, crush it to 40 mesh, add 1000kg of water for extraction, the extraction temperature is 90°C, the extraction time is 3.5h, and the supernatant is concentrated to 50kg after centrifugation. 4. Take jujube, medlar, cordycep...

Embodiment 2

[0092] Embodiment 2: 1. Get 73.6 kg of fresh sea cucumber after removing the intestines, add 80 kg of ice water and homogenize it. The homogenization should be fine, so that the sea cucumber particles are less than 0.5 cm. Take the entire homogenate, add 500kg of water, and then use trypsin to hydrolyze. The amount of enzyme added is 0.33kg. The sea cucumber enzymatic hydrolyzate is centrifuged, and the supernatant is the sea cucumber extract. Activated carbon is used to decolorize and deodorize the extract. 2. The sea cucumber extract liquid is heated and concentrated to 80kg. 3. Take 11.5kg of dried black fungus, crush it to 40 mesh, add 380kg of water for extraction, the extraction temperature is 90°C, the extraction time is 3.5h, and the supernatant is concentrated to 20kg after centrifugation. 4. Take jujube, medlar, cordyceps, hawthorn, and chrysanthemum respectively at 2.3kg, 1.725kg, 0.575kg, 2.875kg, and 1.15kg, add 35kg of water, boil in a frying pan for 2 hours, a...

Embodiment 3

[0093] Embodiment three: 1. Get 71.04 kg of fresh sea cucumber after removing the intestines, add 70 kg of ice water and homogenize it. The homogenization should be fine, so that the sea cucumber particles are less than 0.5 cm. Take the entire homogenate, add 520kg of water, and then use trypsin to hydrolyze, the amount of enzyme added is 0.53kg, the enzymolysis temperature is 60°C, the enzymolysis time is 4h, the enzyme is inactivated at 100°C for 10min, and the enzyme is stirred properly during the enzymolysis process. The sea cucumber enzymatic hydrolyzate is centrifuged, and the supernatant is the sea cucumber extract. Activated carbon is used to decolorize and deodorize the extract. 2. The sea cucumber extract is heated and concentrated to 80kg. 3. Take 22.08kg of dried black fungus, crush it to 40 mesh, add 600kg of water for extraction, extraction temperature is 90°C, extraction time is 3.5h, and the supernatant is concentrated to 30kg after centrifugation. 4. Take ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com