Flow rate measuring device

一种流速测量、流体的技术,应用在流速测量装置领域,能够解决流速检测件输出线性度降低、减小装置的尺寸存在限制、难高精度的测量等问题,达到减小尺寸、避免故障、高测量精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Embodiments of the present invention will be described with reference to the drawings from FIG. 1 to FIG. 16 .

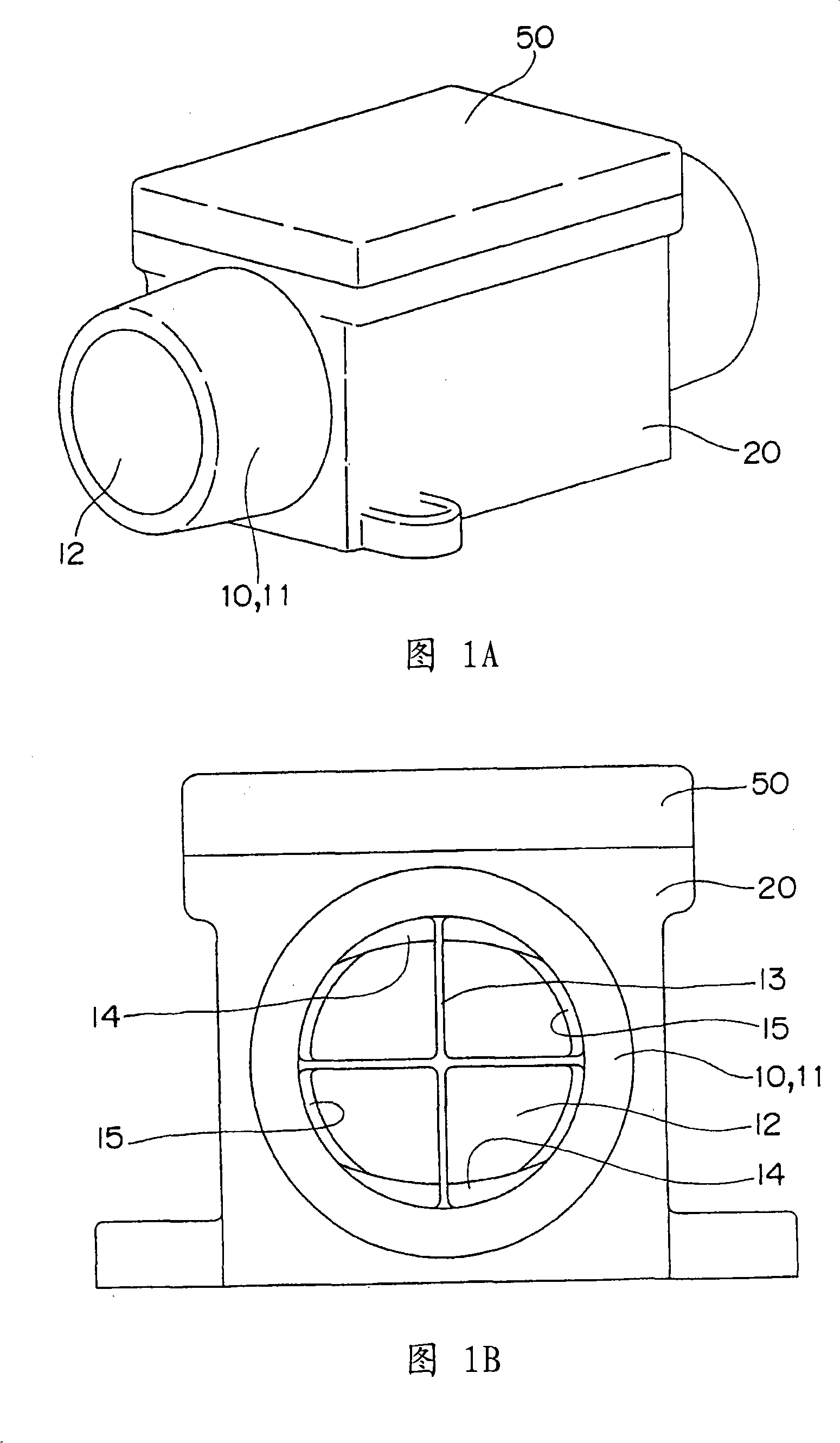

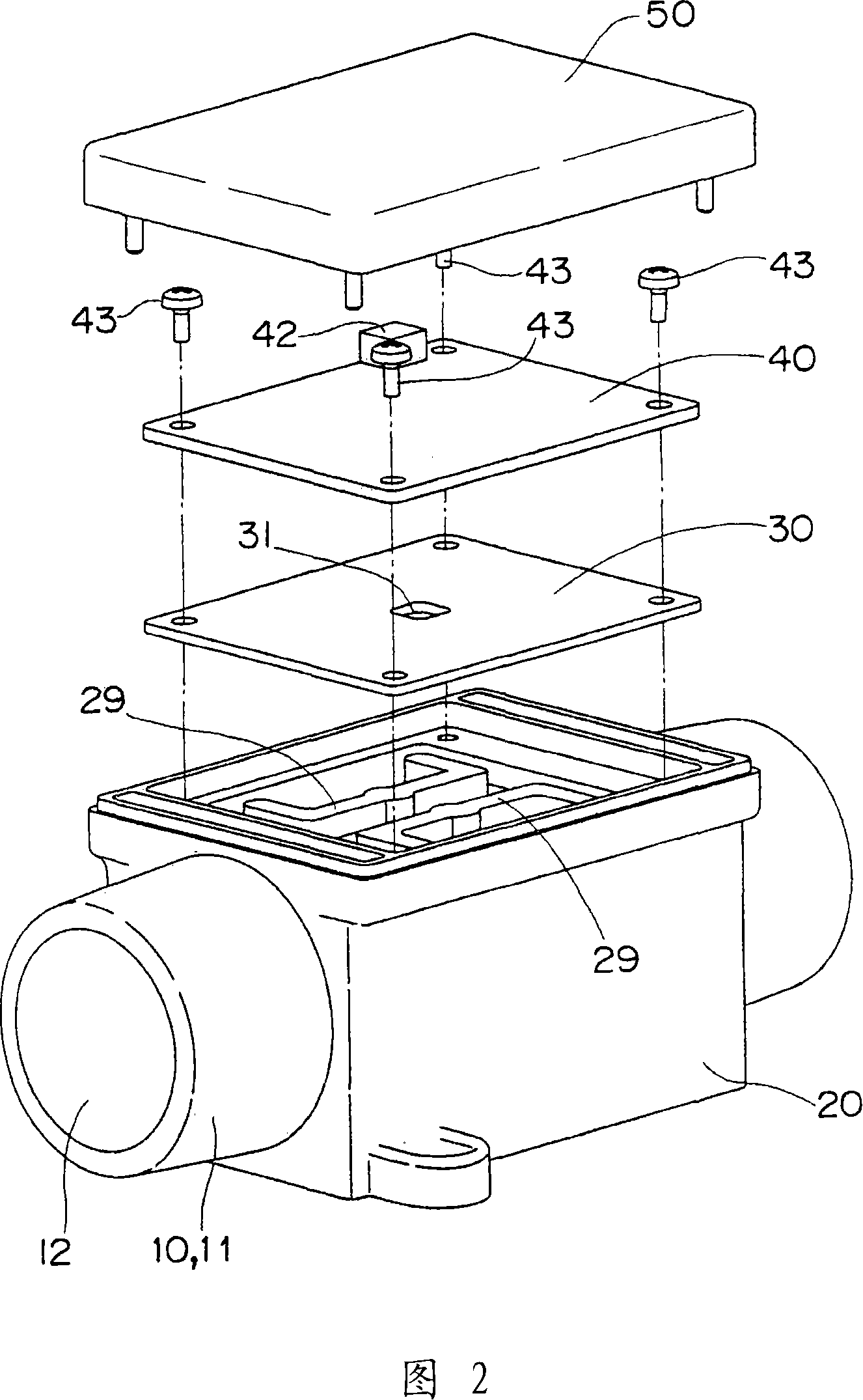

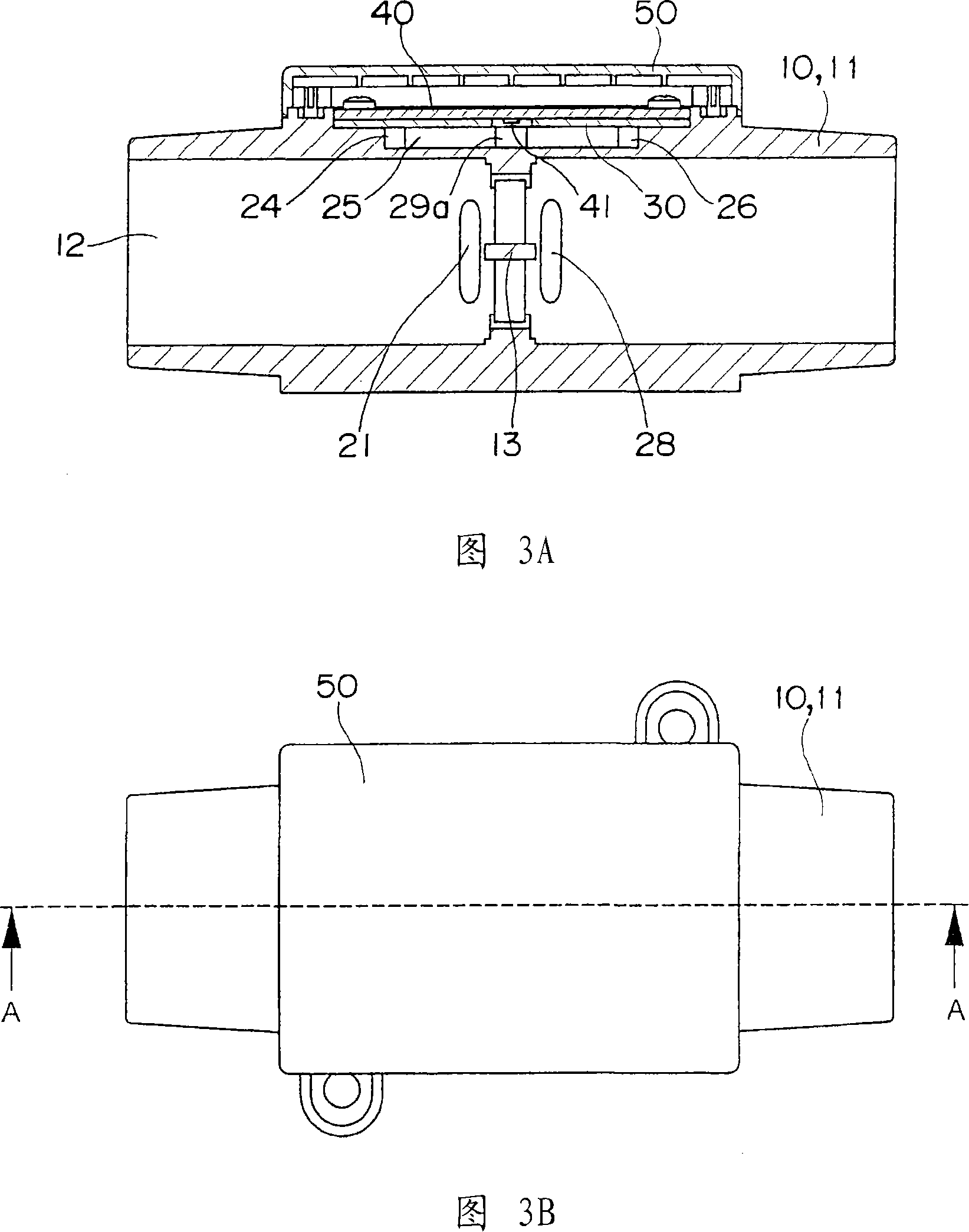

[0079] As shown in FIGS. 1 and 2 , the flow rate measuring device of this embodiment includes: a base body 10 integrally molded with a secondary flow channel block 20 for forming a secondary flow channel on the outer peripheral surface of the main flow tube 11 channel; a sealing plate 30 having a measuring hole 31 at its center portion and sealing the opening of the secondary flow channel block 20; a circuit board 40 having a flow velocity detecting member 41 to be inserted through the measuring hole 31 at its center and its lower surface, which stacked on the sealing plate 30 ; and a cover 50 for covering the opening of the secondary flow channel block 20 . The sealing plate 30 and the circuit board 40 are fixed to the secondary flow channel block 20 by screws 43 .

[0080] The base body 10 is provided with a cross-shaped orifice 13 at a central portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com