Microwave sulphur lamp bulb connection structure

A technology for connecting structures and light bulbs, applied in discharge lamps, electrical components, circuits, etc., can solve the problems of complicated operation process, easily damaged parts, time-consuming and labor-intensive, etc., and achieve the effect of convenient disassembly and installation, not easy to parts, and not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

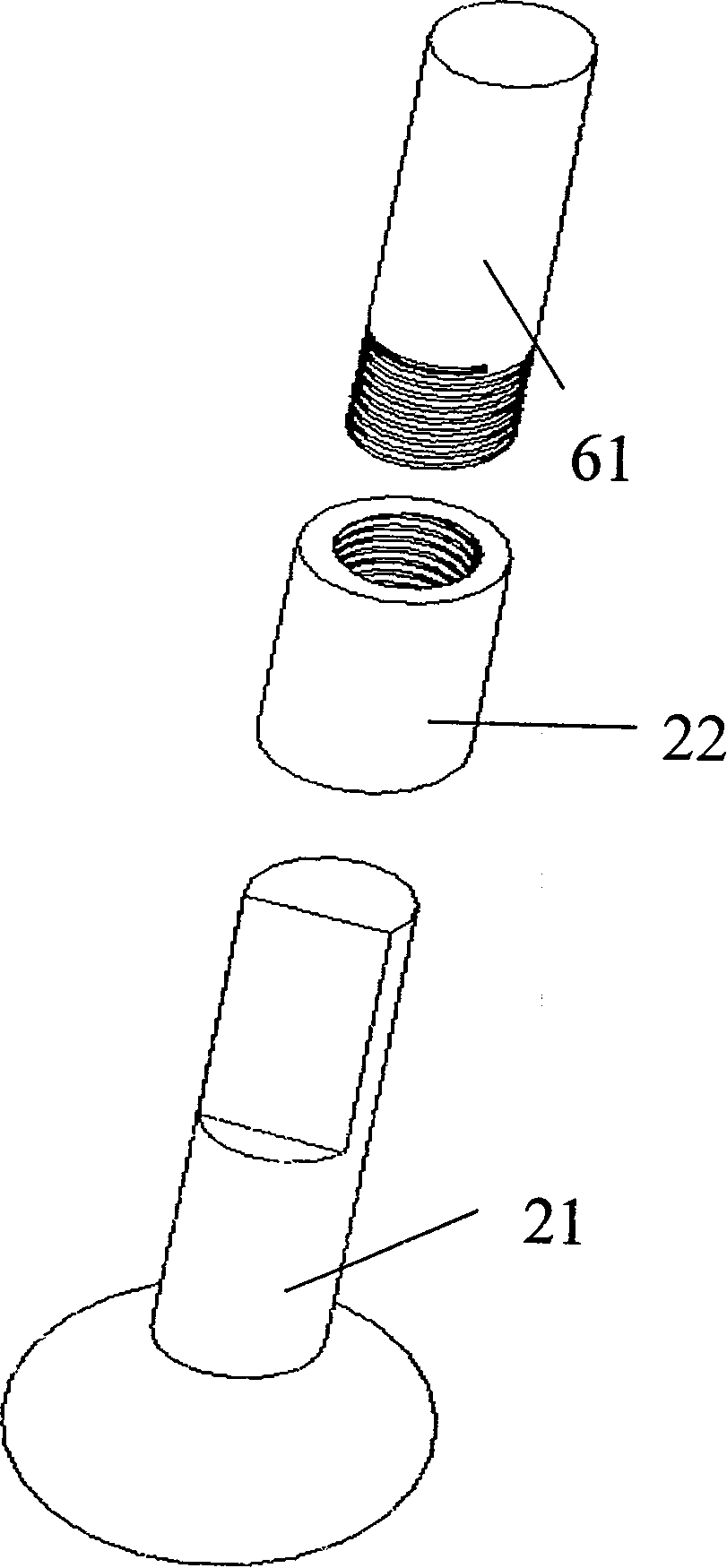

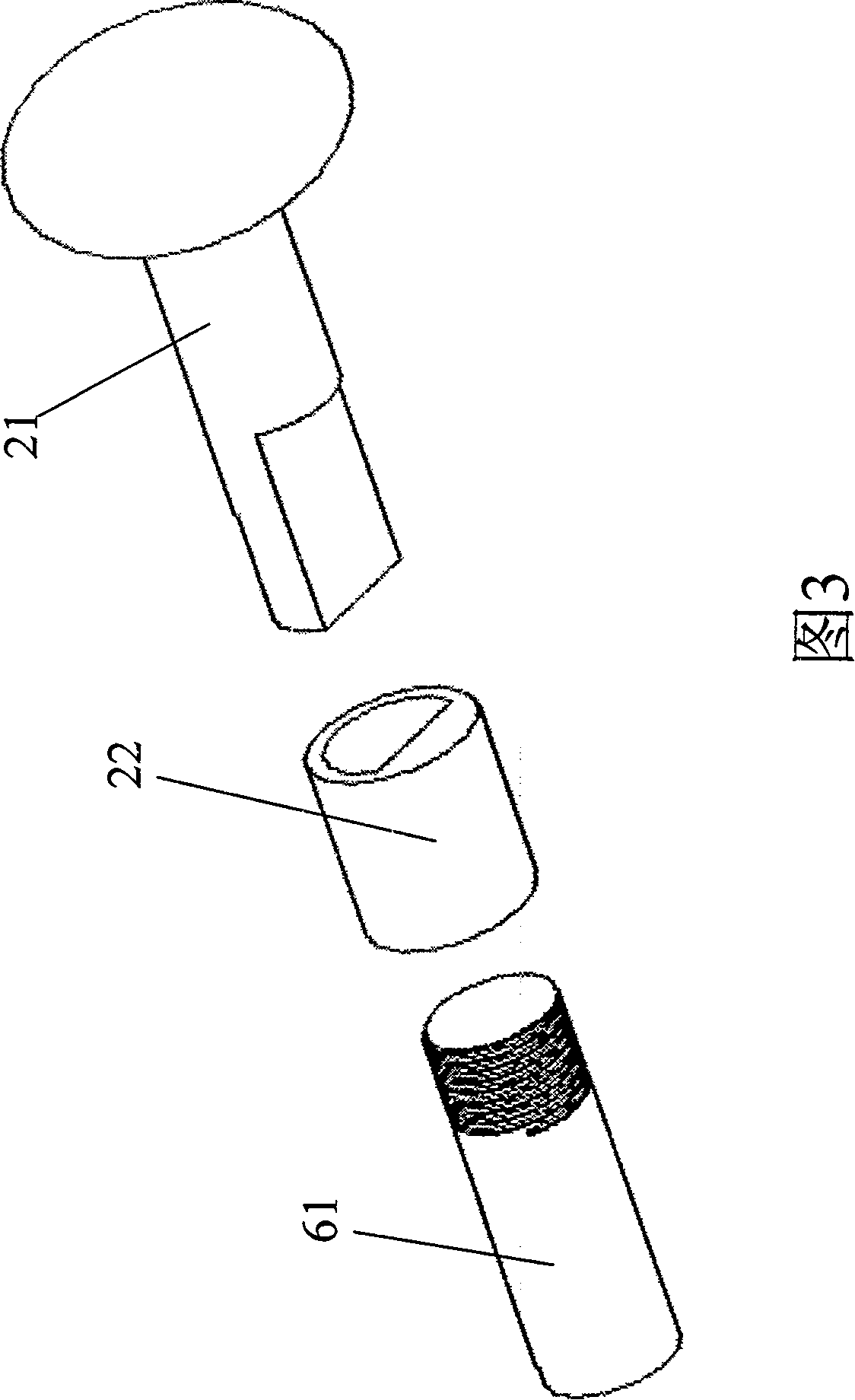

[0020] refer to Figure 4 As shown, the microwave sulfur lamp light bulb connection structure of the present invention includes the light bulb 2, which is made of quartz material, filled with luminescent substances, and the luminescent substances emit light under microwave excitation; the lamp handle 21 is connected to the light bulb 2 by melting and extend to the inside of the housing, the end of the lamp handle 21 away from the bulb 2 is screwed to the motor shaft 61 inside the housing through a cylindrical connector 22; The shape connector 22 is connected through a push-type buckle structure.

[0021] The connection structure of the microwave sulfur lamp light bulb of the present invention, the push-type fastening structure includes: a buckle block 211 is provided on the side wall of the lamp handle 21 away from the end of the light bulb 2, and a buckle block 211 is provided on the inner wall of the cylindrical connector 22 to make the buckle block 211 slide Insert and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com