Range hood integral body smoke-collecting cover top surface single-elevation structure

The technology of a range hood and a fume collecting hood is applied in the field of a single-elevation structure on the top surface of the fume collecting hood of the whole fuselage of the range hood, and can solve the problems of the effect of collecting the fume and the unsatisfactory effect of collecting the dirty oil and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

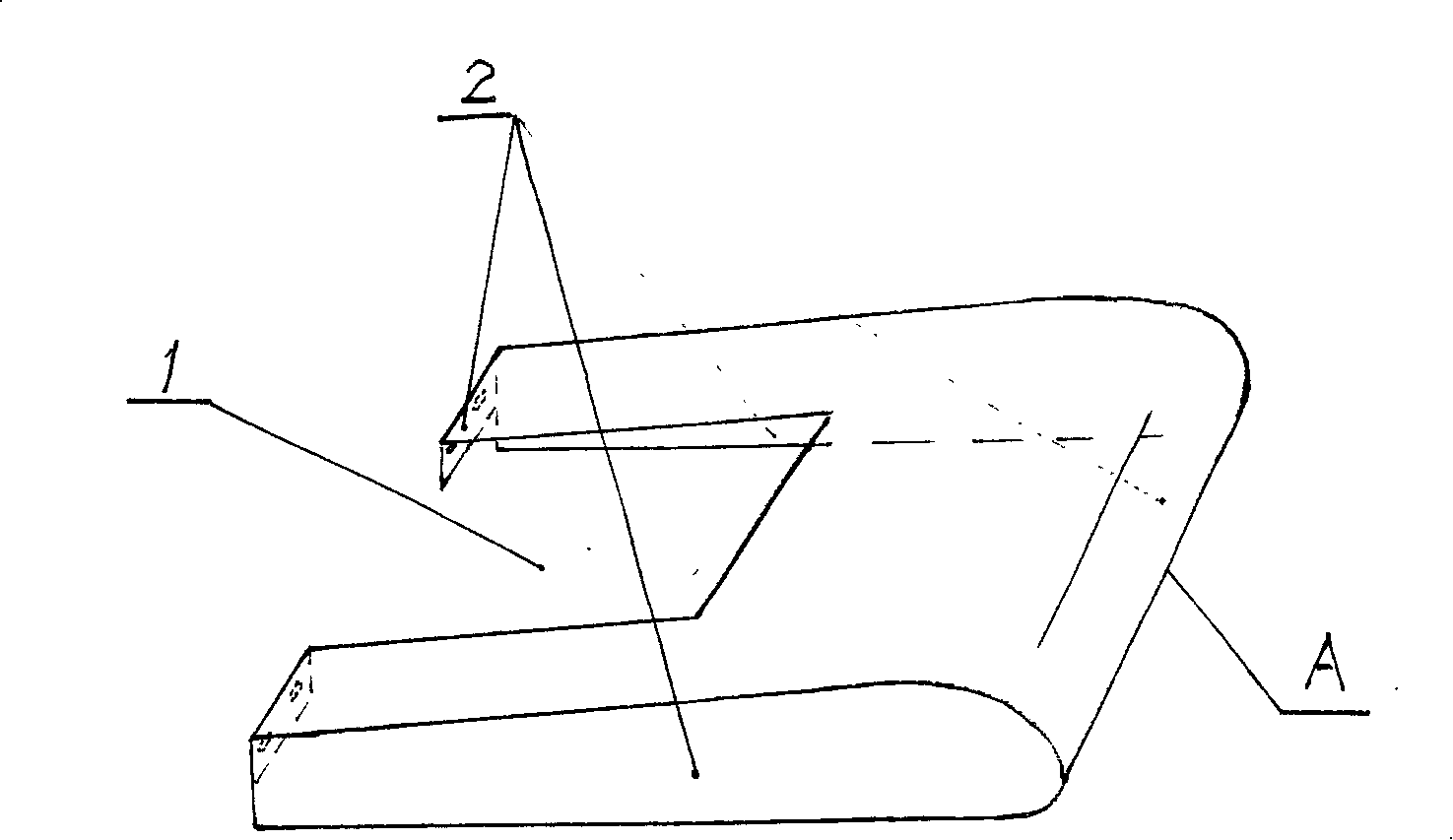

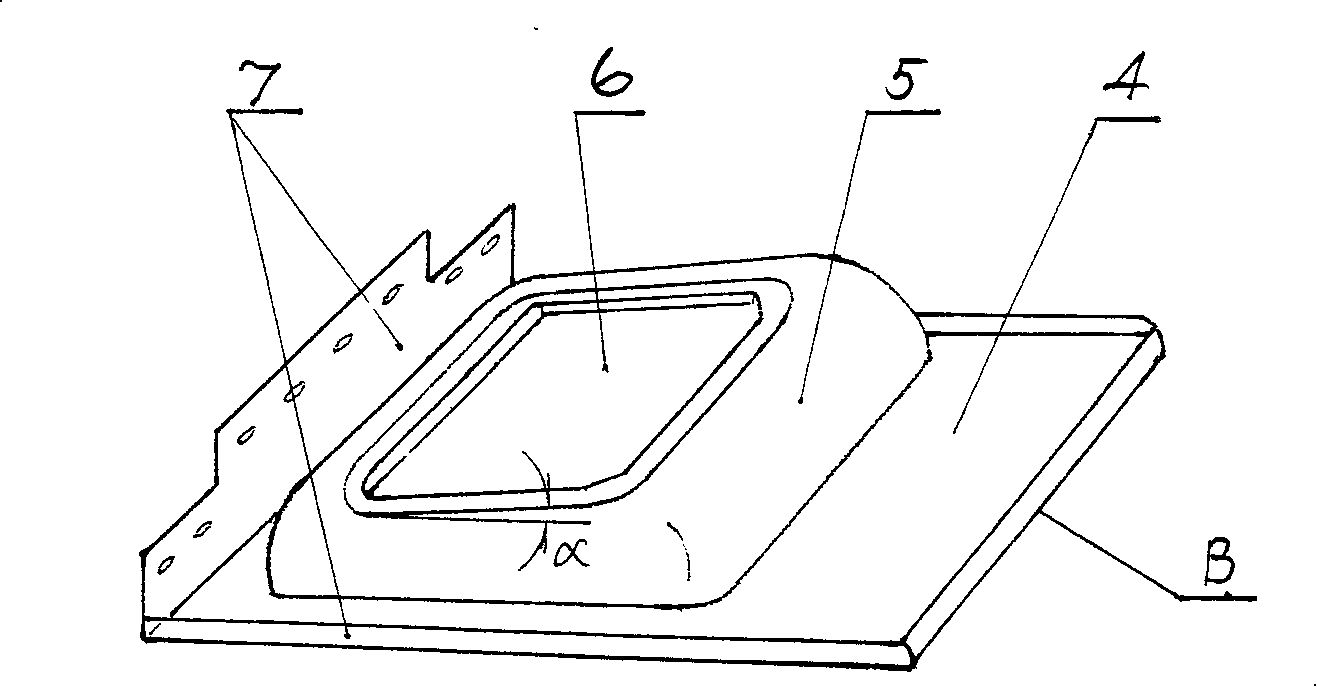

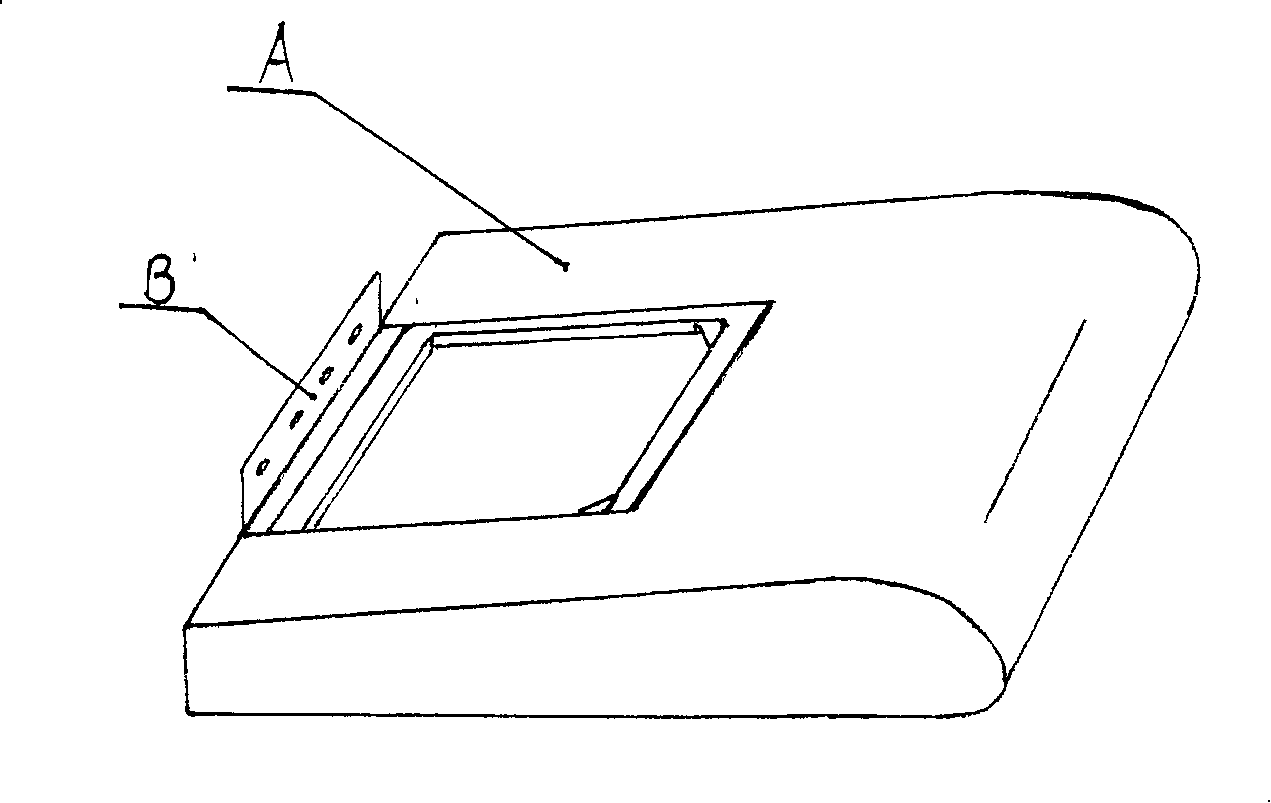

[0017] First, cut the entire metal sheet on the shearing machine according to the expanded size of the cover plate A, and process a gap 1 at the rear and a frame 2 with a height of four sides ≤ 200mm on the machine tool; then follow the expanded size of the smoke hood B Cut the entire metal sheet on the shearing machine, then press the boss 5 on the hydraulic press, and make the top surface of the boss 5 have a horizontal elevation angle α from back to front; and then process it on the machine tool after trimming A central opening 6 on the top surface of the boss 5, and a turning edge 7 with a height of four sides ≤ 200mm. Then connect the fume collecting hood B and the cover plate A up and down and then make it into one by welding, and remove the traces of welding through grinding and polishing, which becomes the single elevation angle of the fume collecting hood top surface of the whole fuselage of the range hood of the present invention structure. Since the top surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com