Pyrite selectivity inhibition technique for secondary copper sulfide mineral biological lixiviation process

A copper sulfide ore bioleaching technology, applied in the direction of microorganisms, microorganisms, process efficiency improvement, etc., can solve problems such as hindering the smooth progress of the leaching process, copper recovery rate decline, copper extraction and electrowinning efficiency reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

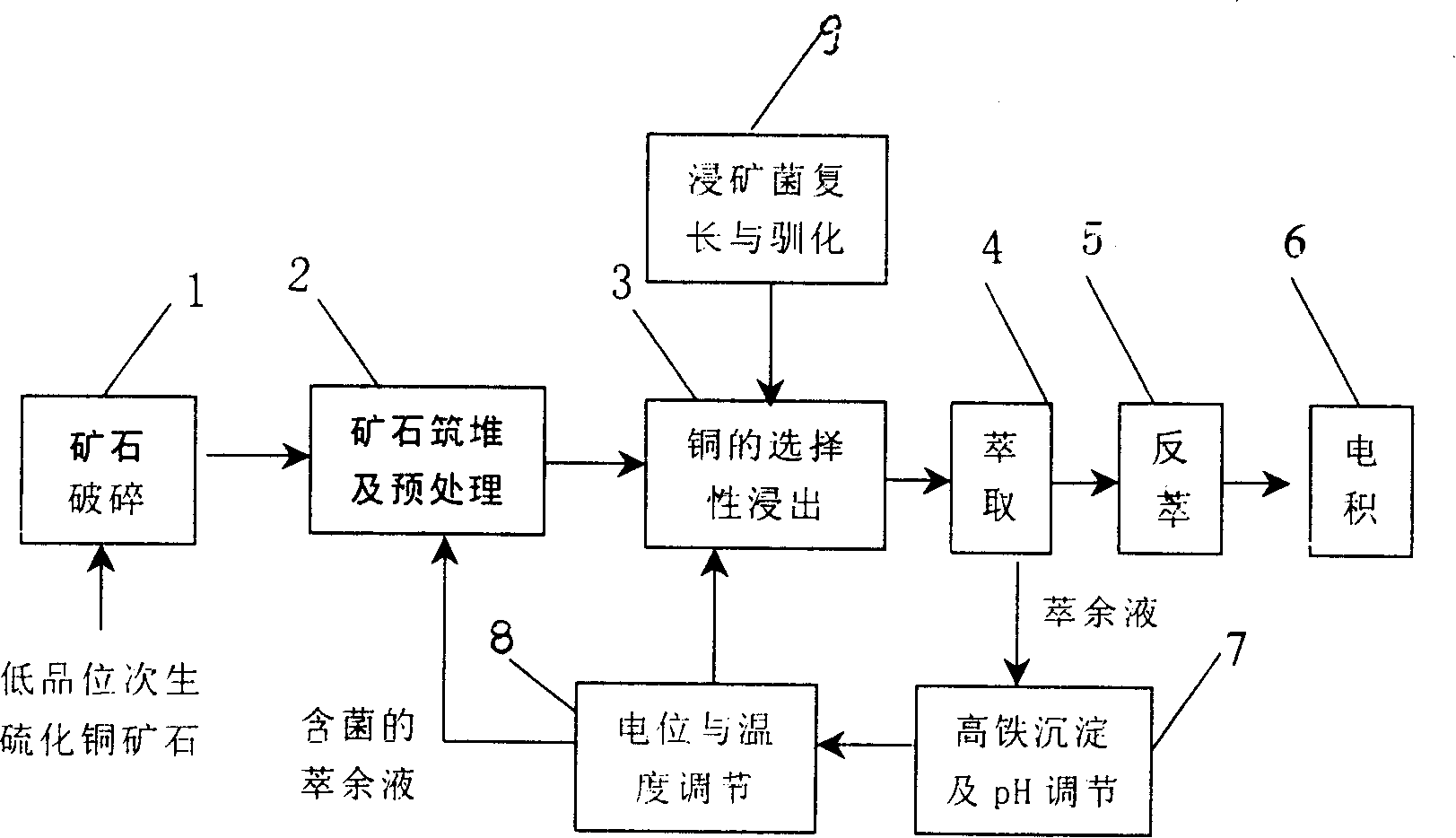

[0032] Such as figure 1 As shown, 1 is the crushing process of low-grade secondary copper sulfide ore; the crushed ore is sent to the ore stacking and pretreatment process; 2; in the pretreatment process, 10-15% of the ore weight is added to the bacteria-containing raffinate, After the ore stacking and pretreatment process, the leaching bacteria obtained by step 9 multiplying and acclimating are added to the leaching step 3. The leachate of step 3 enters the extraction step 4, and the raffinate in step 4 is passed through the step 7 After the adjustment of high iron precipitation and pH value and the potential and temperature adjustment of step 8, return to the leaching step 3 for selective leaching of copper. The copper-containing organic phase extracted in step 4 is sent to the back extraction step 5 for back extraction, after the back extraction The copper-containing rich liquid enters the electrowinning step 6 to obtain electrowinning copper.

[0033] The present invention wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com