Magnetization rectification method for reclaiming acetone from waste acetone menstruum

A technology of waste acetone and acetone, which is applied in the separation/purification of carbonyl compounds, organic chemistry, etc., and can solve the problems of high energy consumption, low efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

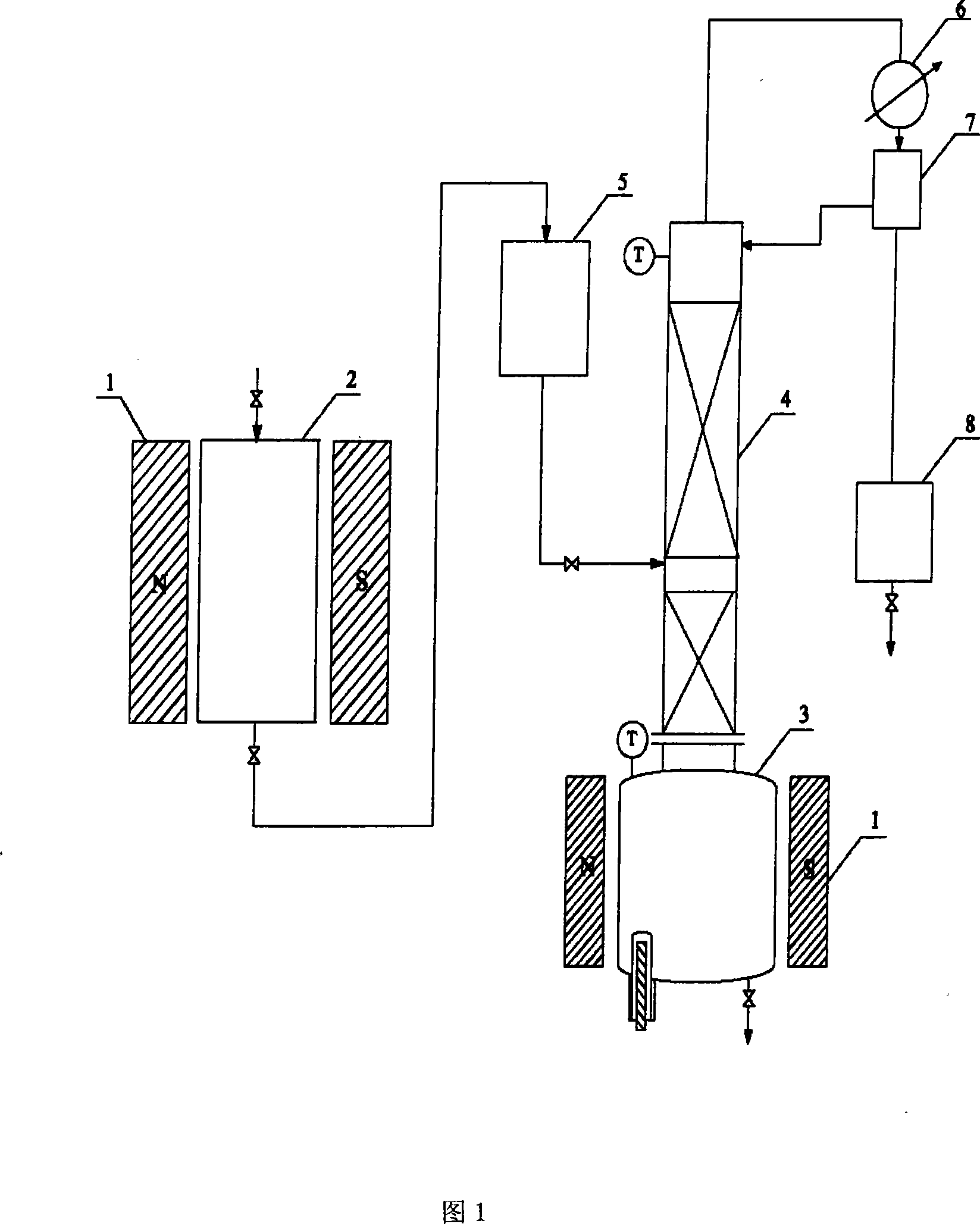

Method used

Image

Examples

Embodiment 1

[0015] A method for reclaiming acetone by magnetic distillation from waste acetone solvent, comprising the steps of:

[0016] (1) Adopt the static magnetization method, in the NdFeB magnetizer whose magnetic induction intensity is 0.515T, add 300mL acetone mass percentage content to be 60.5% waste acetone solvent and carry out magnetization treatment, magnetization treatment time 12h, has reached Magnetic saturation state, stored in the feed tank;

[0017] (2) a neodymium-iron-boron magnetic field with a magnetic induction of 0.45T is arranged outside the rectifying kettle, and the waste acetone solvent (100mL) of the part magnetic saturation state processed through step (1) that is stored in the feed tank is input into the rectifying tank Still, under normal pressure, it is operated in a continuous rectification mode. The operating conditions are: total reflux operation for 0.5h at the beginning, when the temperature at the top of the rectification tower reaches 56.4°C and st...

Embodiment 2

[0023] A method for reclaiming acetone by magnetic distillation from waste acetone solvent, comprising the steps of:

[0024] (1) The waste acetone solvent is placed in an NdFeB magnetizer with a magnetic induction intensity of 0.15T, left to be magnetized for 12 hours, so that the waste acetone solvent reaches magnetic saturation, and stored in a feed tank;

[0025] (2) a neodymium-iron-boron magnetic field of 0.15T is arranged on the outside of the rectifying still, and the waste acetone solvent in the partial magnetic saturation state processed through step (1) that is stored in the feed tank is input into the rectifying still, Under normal pressure, adopt continuous rectification to operate, the operating conditions are: total reflux operation at the beginning for 0.3h, when the temperature at the top of the rectification tower reaches 56.4°C and stabilizes, add the said process to the rectification tower at 20mL / h The waste acetone solvent in the magnetic saturation state...

Embodiment 3

[0027] A method for reclaiming acetone by magnetic distillation from waste acetone solvent, comprising the steps of:

[0028] (1) Place the waste acetone solvent in an NdFeB magnetizer with a magnetic induction of 0.515T, let it stand for magnetization for 10 hours, make the waste acetone solvent reach magnetic saturation, and store it in the feed tank;

[0029] (2) a neodymium-iron-boron magnetic field of 0.45T is arranged on the outside of the rectification kettle, and the waste acetone solvent of the part of the magnetic saturation state processed through step (1) is stored in the feed tank to input the rectification kettle, Under normal pressure, adopt the continuous rectification mode to operate, the operating conditions are: at the beginning, the total reflux operation is 0.6h, when the rectification tower top temperature reaches 56.4 ℃ and stabilizes, add the said process in the rectification tower at 10mL / h The waste acetone solvent in the magnetic saturation state tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com