Highly effective inner mesh gear pump or motor

A technology of internal gear pump and internal gear, applied in pump, rotary piston pump, rotary or oscillating piston engine, etc., can solve problems such as difficult axial leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

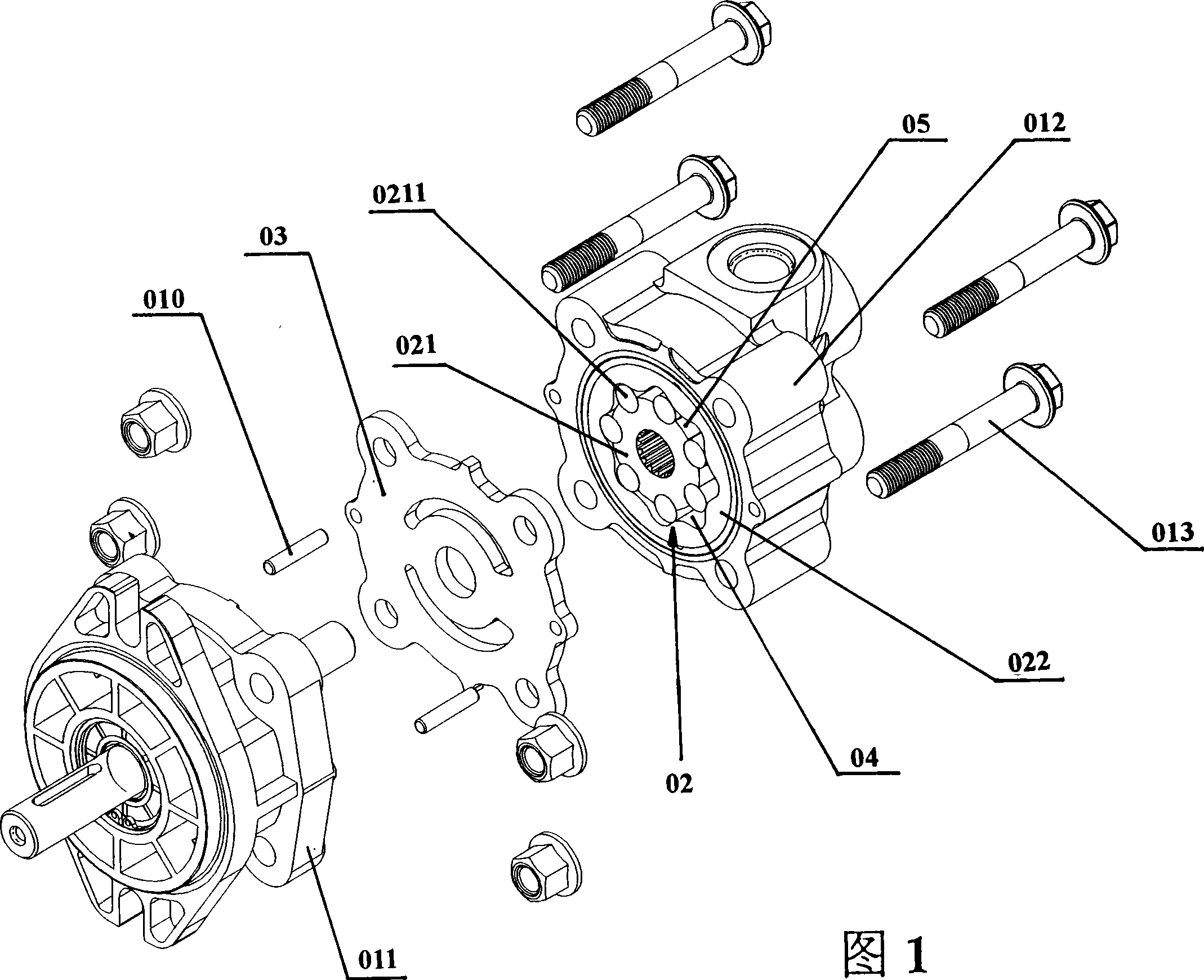

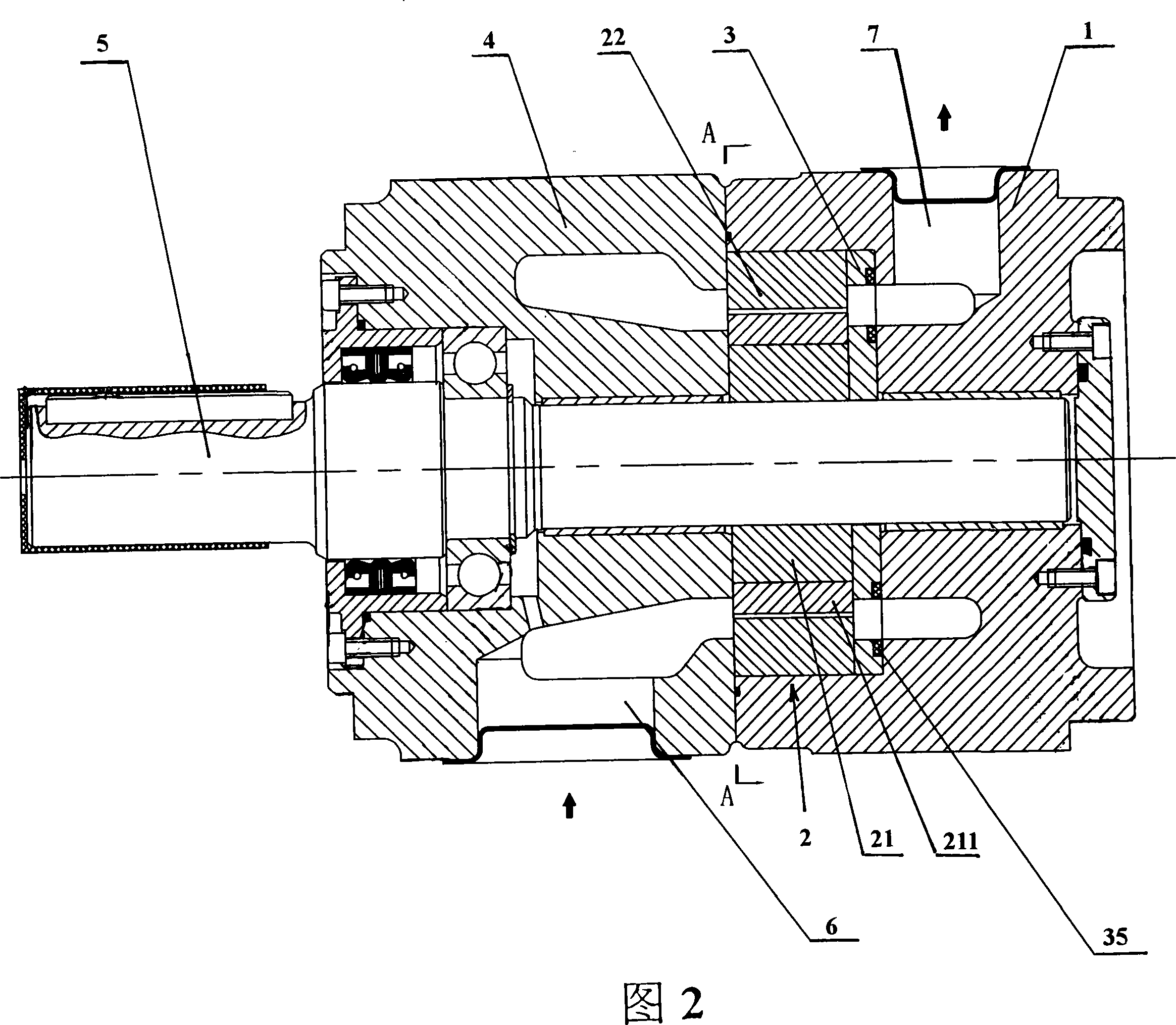

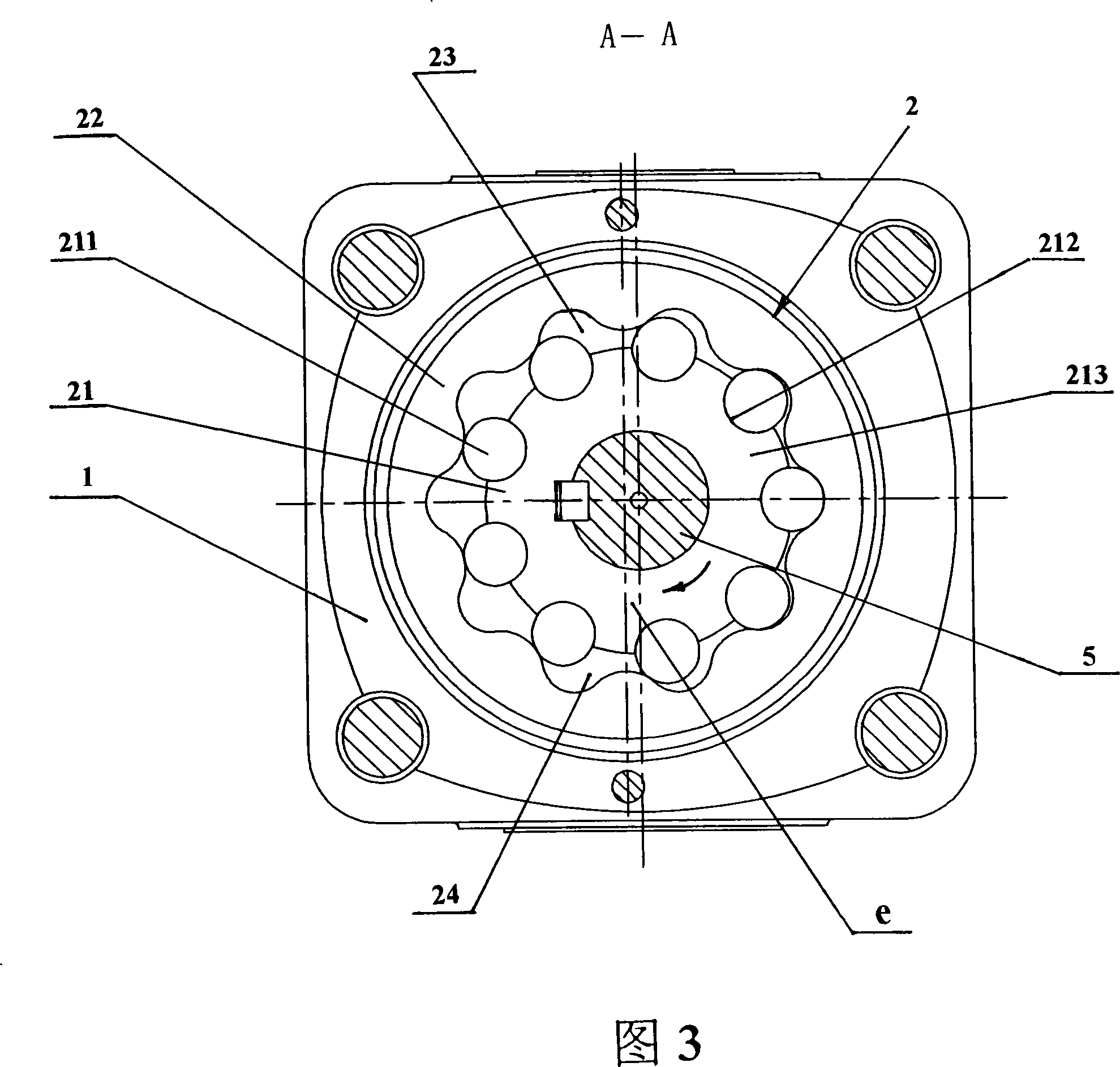

[0024] Please refer to FIG. 2 , a structural sectional view of the present invention, which shows that the high-efficiency internal gear pump includes a housing 1 , an internal gear pair 2 , a pressure compensation side plate 3 , a front cover 4 and a shaft 5 . The internal meshing gear pair 2 and the pressure compensating side plate 3 located on the side of the internal meshing gear pair 2 are jointly accommodated in the inner hole of the housing 1 and both pass through the shaft 5. The pressure compensating side plate 3 is The internal meshing gear pair 2 and the housing 1 can move freely along the axial direction of the shaft 5; The compensation side plate 3 is sealed in the inner cavity of the housing 1 formed by the inner hole, and the front cover 4 has an oil inlet hole 6 communicating with the low-pressure volume chamber 24 (see FIG. 3 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com