A flexible seal-rotor system shallow grooved sleeve that improves lift

A flexible sealing, shallow groove technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as reducing delay time, and achieve the effect of reducing leakage, reducing axial leakage, and solving hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

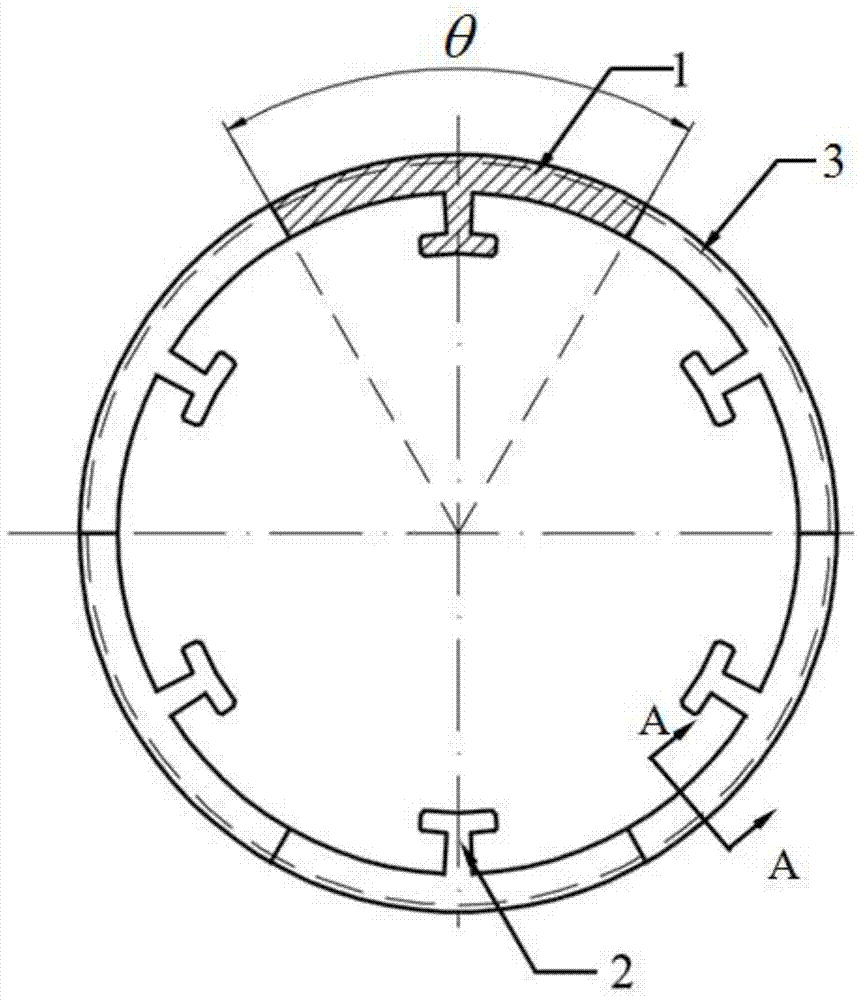

[0020] combine figure 1 , the technical solution adopted in the present invention is: by designing a sleeve device nested on the surface of the rotor, the special structure of the shallow groove surface evenly distributed on the outer surface of the sleeve increases the gas lift of the leakage gas, and this lift makes the flexible seal ( The lower end of the fingertip seal) is lifted in time to improve the adaptability of the flexible seal. The composition of the shallow groove surface sleeve of the seal-rotor system includes a ring sleeve 1, a T-shaped buckle 2 and a shallow groove 3 on the outer surface. The sleeve can be installed as a whole, or assembled from 2-6 fan-shaped rings as required. Among them, the T-shaped buckle is used for clamping between the sleeve and the rotating shaft, and the buckle and the sleeve are integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com