Liming stirring technique automatic control method

A technology of mixing process and control method, which is applied in the field of gelatin production process, can solve the problems of leakage in the liming tank, high labor intensity, low production efficiency, etc., and achieve the effect of reducing labor intensity, high degree of automation, and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

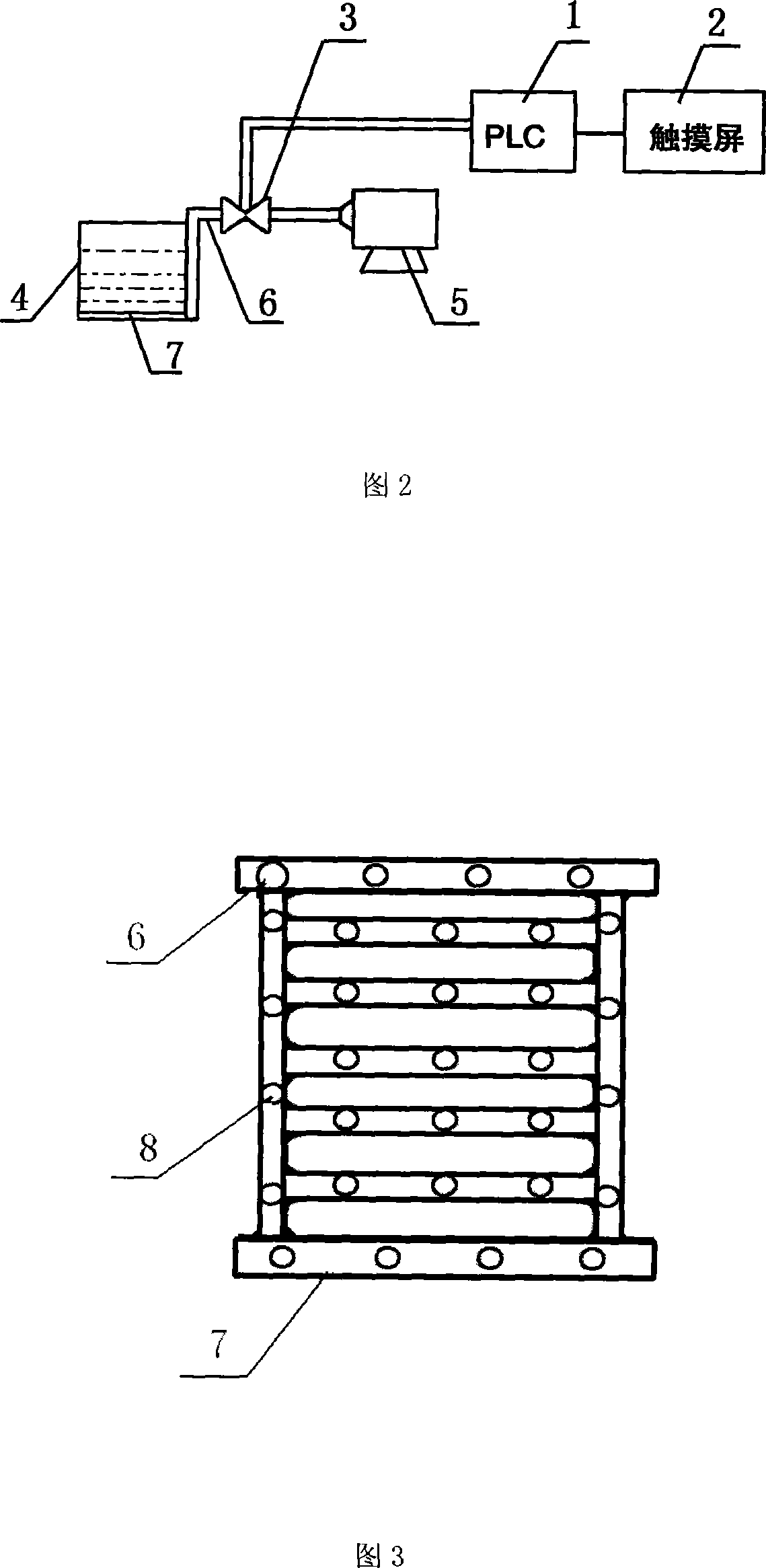

[0024] Take Φ80 stainless steel pipes and weld a frame with a length of 5.2 meters and a width of 4.9 meters, and then weld at least five connecting pipes in the longitudinal or transverse direction of the frame to form the stirring pipe 7. The frame pipes and connecting pipes are connected to each other, and the stirring pipe 7 faces upward One side pipe wall is uniformly drilled out blast hole 8; Stirring tube 7 is arranged on the bottom of the liming pool with a length of 5.2 meters, a width of 4.9 meters and a depth of 2.3 meters upwards according to the blast hole 8. The corners on one side are welded with holes, the other end of the compressed air pipeline 6 is connected to the solenoid valve 3 fixed on the pipe frame, and the solenoid valve 3 is connected to the compressed gas station 5 through the pipeline 6 .

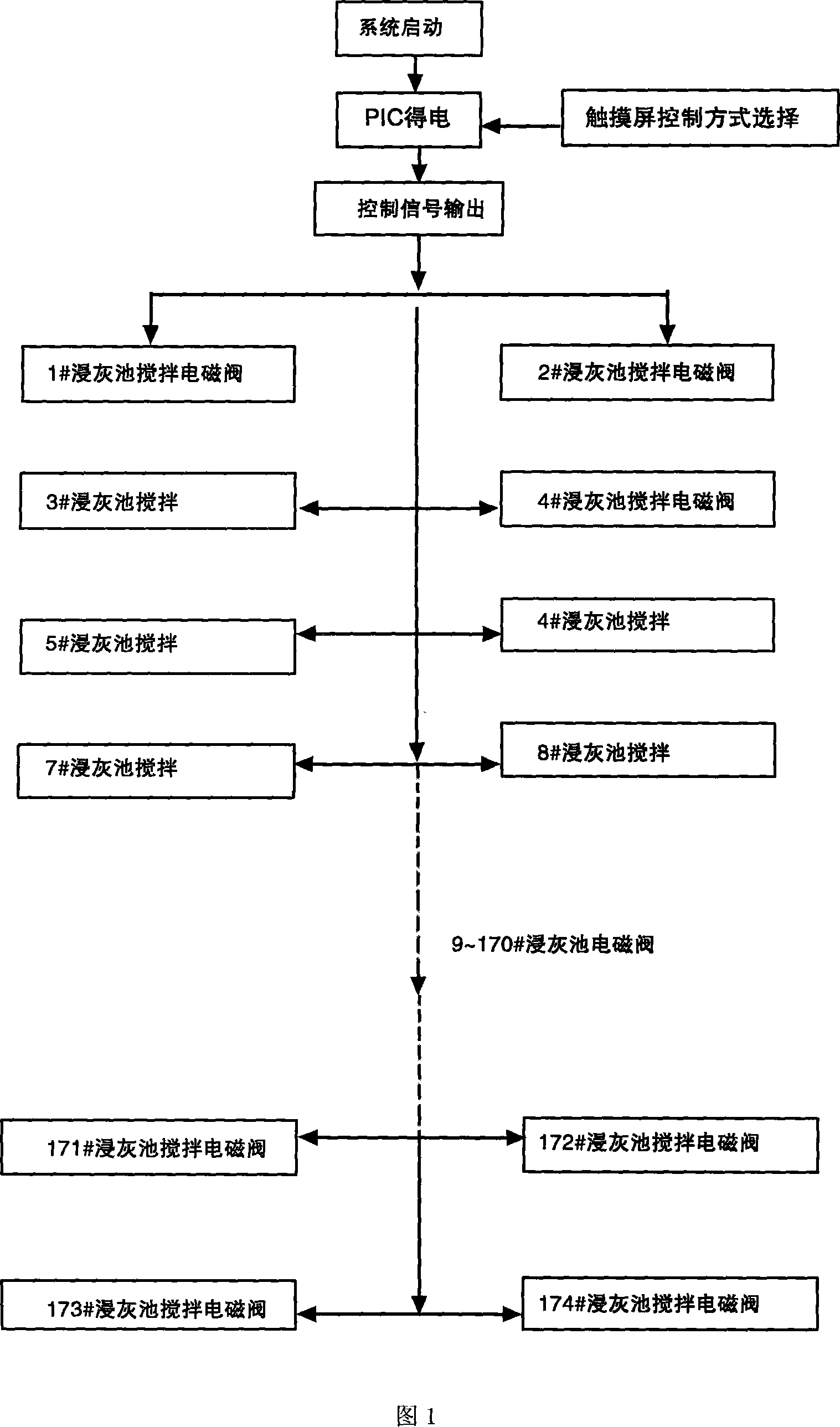

[0025] 174 stirring electromagnetic valve 3 control cables are connected with the keys corresponding to the liming tank number on the upper monitoring touch scr...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, except that the agitation control mode of any designated liming tank is selected as pressing the key of the agitation control mode on the upper monitoring touch screen 2, selecting any designated agitation mode button, and then pressing the button on the upper monitoring touch screen 2 Liming pool number button, the pressed limening pool starts to stir.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com