Vibration-free self-flowing dense concrete

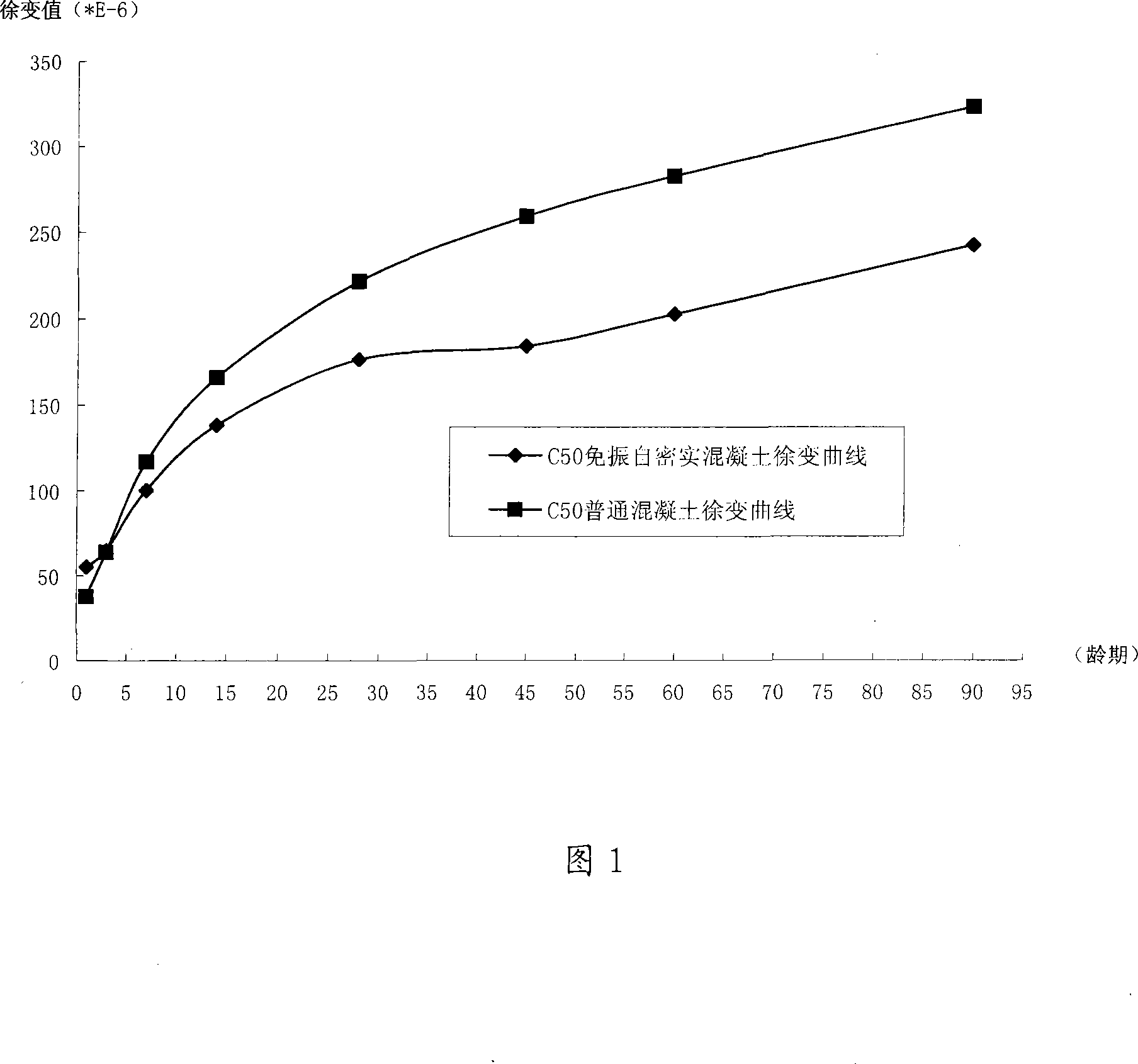

A technology of compacting concrete and apparent density, applied in the field of building materials, can solve the problems of complex shape, non-compact structure quality, difficulty in vibrating, etc., and achieve the effect of small loss value over time, excellent durability, and good workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment. This embodiment is a model that combines the lower flange of the concrete T-beam structure, the junction position between the web of the concrete box girder and the bottom plate, and other parts that are difficult to pour concrete, and corresponding test pieces. The left half of the model simulates the T-beam structure, while the right half simulates the structure at the junction of the box girder web and the bottom plate; in the lateral distribution, the main reinforcement is divided into three types of spacing, and the three kinds of reinforcement spacing are 4.5cm, 6.4 cm, 8.9cm, the spacing between reinforcements gradually increases, and three corrugated pipes are arranged on the T-shaped structure as channels for prestressed reinforcement; the stress reinforcement in the model is φ16mm ribbed reinforcement, and the stirrup is φ8mm light garden reinforcement; the volume content of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com