Method for reclaiming waste sulfuric acid in hard anode oxidation process

A technology of hard anodic oxidation and waste sulfuric acid, which is applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of low value of hard anodic oxidation, loss of additives, high treatment cost, etc., and achieve high added value, low cost of equipment transformation, and treatment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 5 liters of sulfuric acid solution whose aluminum ions have exceeded the standard during the hard anodizing process from the workshop and move it from the hard anodizing tank to the spare tank at a temperature of -5 to 5°C through the cooling pipe. The conditions are as follows:

[0037] Sulfuric acid (H 2 SO 4 ): 150~250g / L

[0038] Aluminum ions (Al 3+ ) 2~15g / L

[0039] Temperature: -5~5℃

[0040] Current density: 2.0~4.0A / dm 2

[0041] Voltage: 0~100V

[0042] Time: 30~40min

[0043] Agitation: Intense agitation with compressed air.

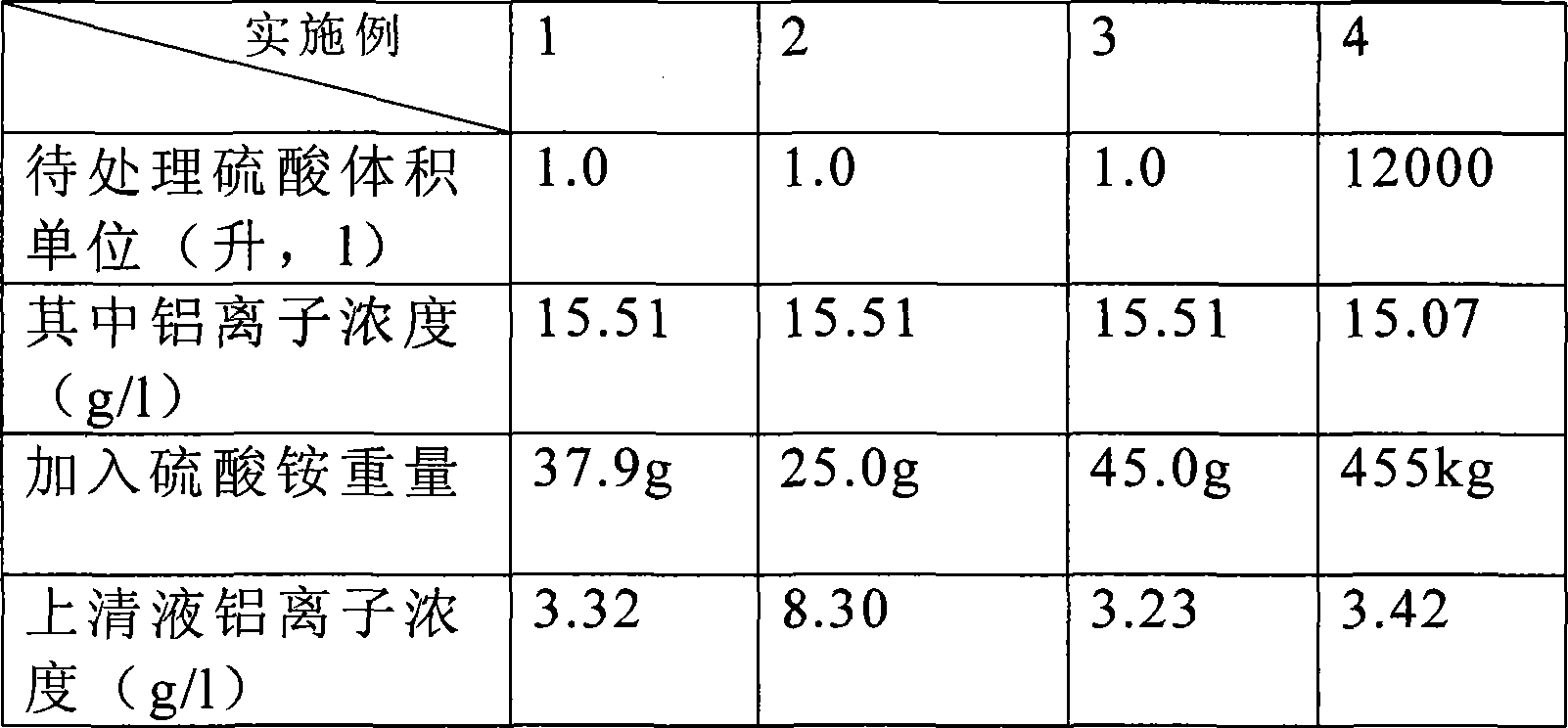

[0044]The concentration of aluminum ions in it was determined to be 15.51g / l through assay. Use a 1-liter volumetric flask to sample 1 liter, weigh 37.9g of ammonium sulfate by calculation and put it into a spare tank, stir to fully dissolve the ammonium sulfate, and then put it into a household freezer to maintain the temperature at -5 to 5°C. 5 hours. The supernatant of the...

Embodiment 2

[0046] Take 5 liters of sulfuric acid solution whose aluminum ions have exceeded the standard during the hard anodizing process from the workshop and move it from the hard anodizing tank to the spare tank at a temperature of -5 to 5°C through the cooling pipe. The conditions are as follows:

[0047] Sulfuric acid (H 2 SO 4 ): 150~250g / L

[0048] Aluminum ions (Al 3+ ) 2~15g / L

[0049] Temperature: -5~5℃

[0050] Current density: 2.0~4.0A / dm 2

[0051] Voltage: 0~100V

[0052] Time: 30~40min

[0053] Agitation: Intense agitation with compressed air.

[0054] The concentration of aluminum ions in it was determined to be 15.51g / l through assay. Use a 1-liter volumetric flask to sample 1 liter, weigh 25g of ammonium sulfate into the spare tank by calculation, stir to fully dissolve the ammonium sulfate, and then put it into a household freezer to maintain a temperature of -5 to 5°C at 0.5 to 5 Hour. The supernatant of the compl...

Embodiment 3

[0056] Take 5 liters of sulfuric acid solution whose aluminum ions have exceeded the standard during the hard anodizing process from the workshop and move it from the hard anodizing tank to the spare tank at a temperature of -5 to 5°C through the cooling pipe. The conditions are as follows:

[0057] Sulfuric acid (H 2 SO 4 ): 150~250g / L

[0058] Aluminum ions (Al 3+ ) 2~15g / L

[0059] Temperature: -5~5℃

[0060] Current density: 2.0~4.0A / dm 2

[0061] Voltage: 0~100V

[0062] Time: 30~40min

[0063] Agitation: Intense agitation with compressed air.

[0064] The concentration of aluminum ions in it was determined to be 15.51g / l through assay. Use a 1-liter volumetric flask to sample 1 liter, weigh 45g of ammonium sulfate by calculation and put it into a spare tank, stir to fully dissolve the ammonium sulfate, and then put it in a household freezer to maintain a temperature of -5 to 5°C at 0.5 to 5 Hour. The supernatant of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com