Manufacturing technique for formed activated carbon

A technology of forming activated carbon and manufacturing process, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as high cost and unenvironmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

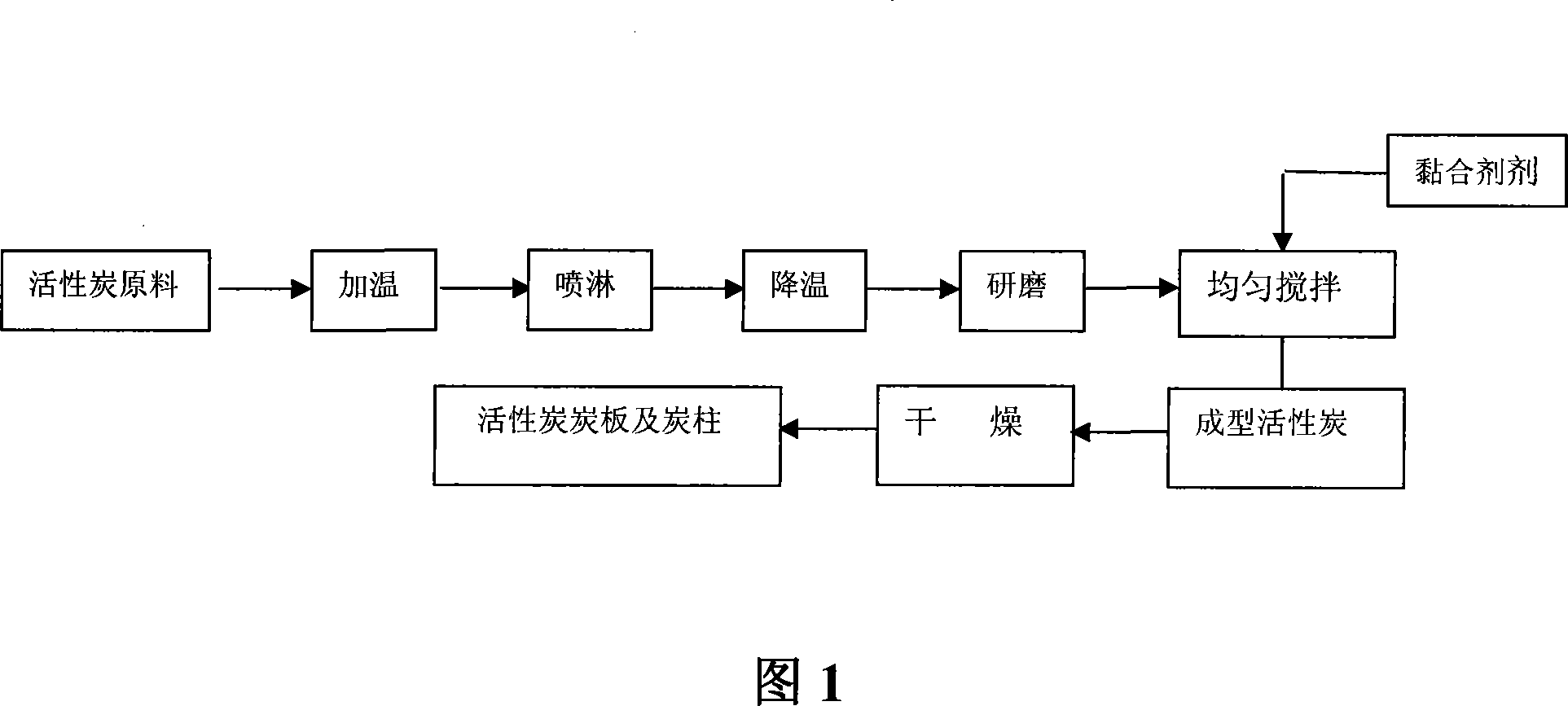

[0011] As shown in Figure 1, a manufacturing process of shaped activated carbon includes: putting the fruit shell into a carbonization furnace and heating it to about 950°C; then adding water to spray and form high-pressure water vapor; Take it out of the oven at natural temperature; put it into a ball mill and process it into about 200 mesh (0.074 mm); mix it with a non-toxic, odorless, and non-polluting adhesive in a 1:1 ratio and stir evenly; put it in a drying oven at about 145°C Take out after about 45 minutes, both get described extruded gac.

[0012] A kind of manufacturing technology that adopts above-mentioned shaped activated carbon to manufacture activated carbon carbon plate, comprises: described shaped activated carbon is extruded into carbon plate or carbon column by hydraulic press; With extruded carbon plate or carbon column air-dried; Air-dried The carbon plate or carbon column is polished and polished to make activated carbon carbon plate or carbon column.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com