Principal shaft of low-speed direct driving type aerogenerator

A wind turbine, direct-drive technology, applied to shafts, electrical components, electromechanical devices, etc., can solve the problems of high material cost, long production cycle, and high manufacturing cost, and can ensure bending and torsion resistance. The effect of reducing the material and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

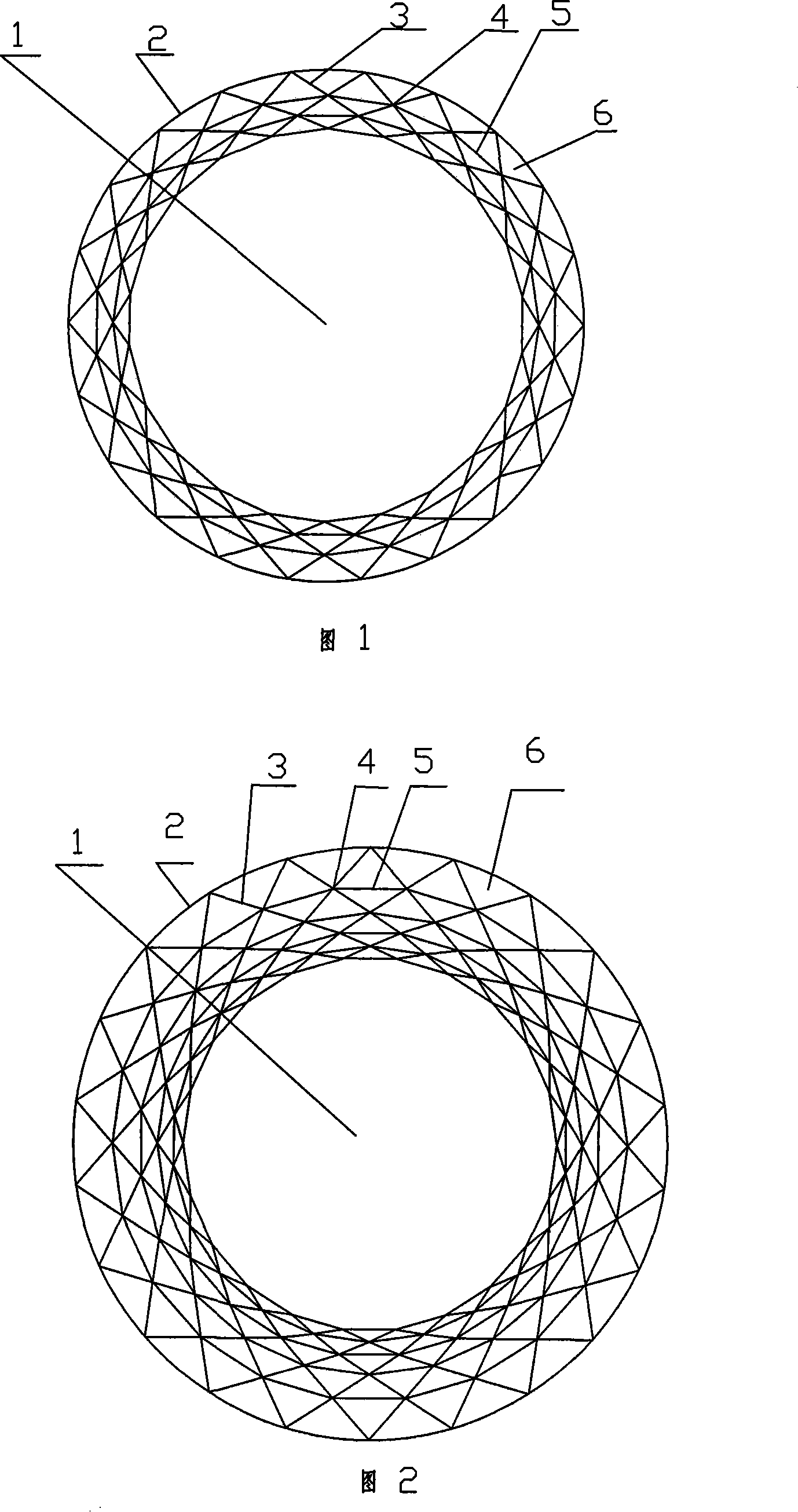

[0017] Figure 1 is a low-speed direct-drive wind turbine main shaft, in Figure 1, made of steel plate, angle steel, the main shaft 1 is a welded structure of a hollow cylinder, its cross-section is circular, the cylinder of the cylinder Part of it is composed of honeycomb grid-like cavity columns arranged regularly in the same direction. Firstly, the outer cylinder 2 made of a 20mm steel plate is rolled by a plate rolling machine, and the cylinder part of the cylinder is welded in sequence around the inner wall of the outer cylinder 2 rolled by the steel plate using 22 long angle steels 3, and welded on the outer wall of the outer cylinder 2. The minimum side width of the angle steel around the inner wall of the cylinder 2 is a right-angle steel with a side length of 120mm, equal sides and equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com