Non-reflection high light extracting rate unit WLED power expanding type high power WLED light source

A high-power, light source technology, applied in the direction of electroluminescent light source, light source, electric light source, etc., can solve the problems of LED chip luminous attenuation, LED chip temperature rise, and reduce luminous efficiency, etc., to achieve small light interference and low chip density. Small, the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

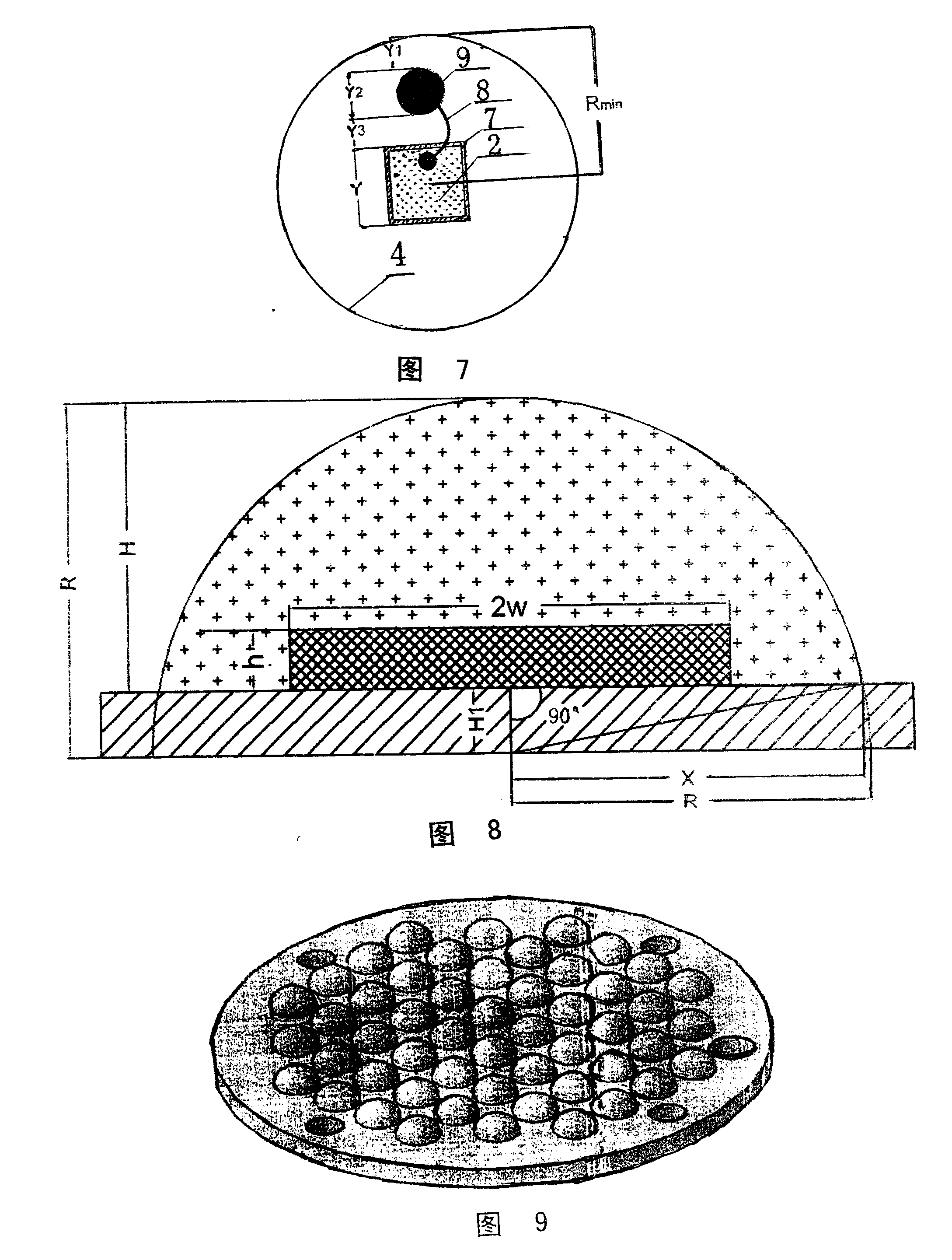

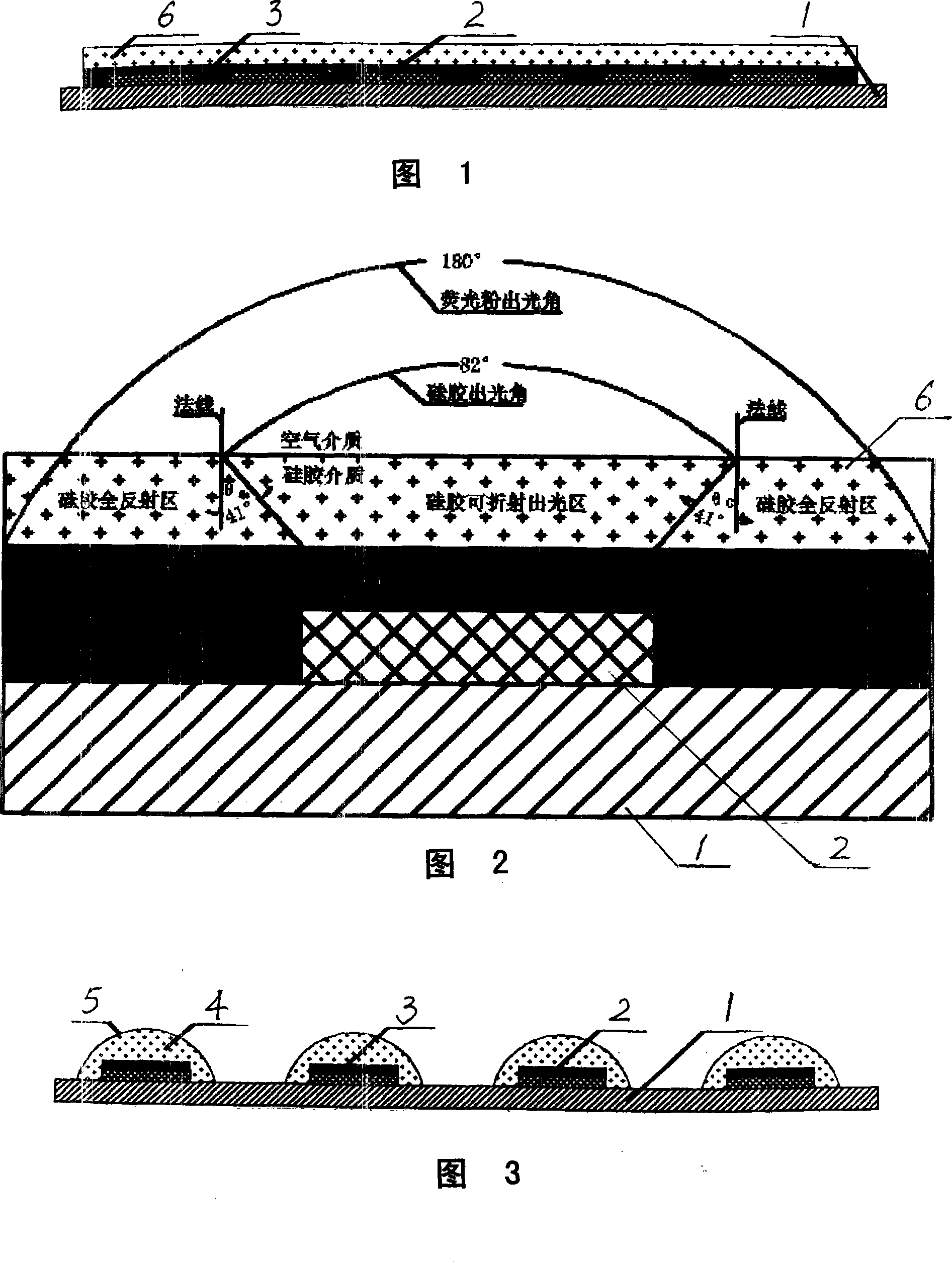

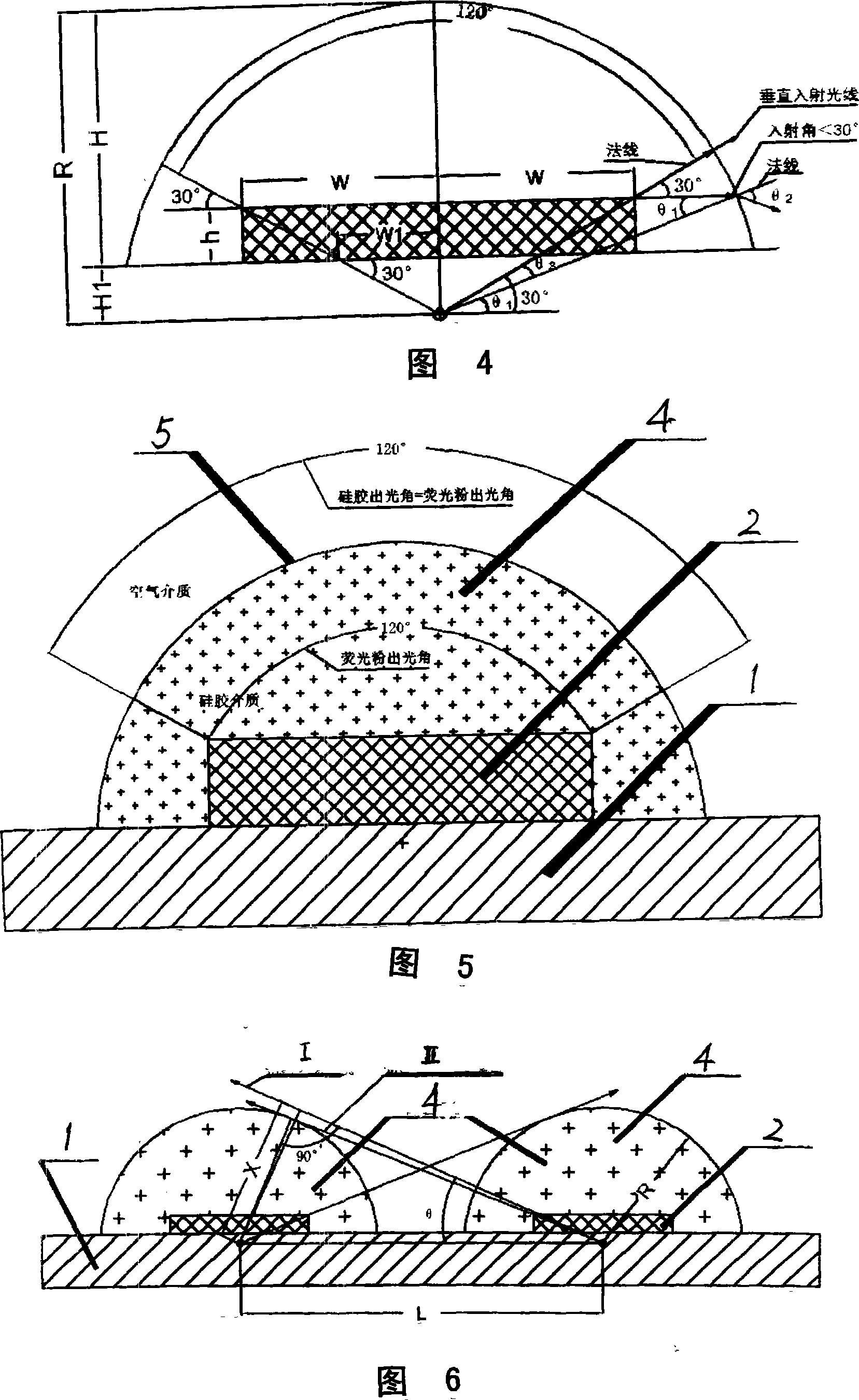

[0056] Referring to Figures 3 to 5, a plurality of blue light BLED chips 2 with a light emission width of 2w are welded on the heat dissipation substrate 1 in a determinant light array; each BLED chip 2 is coated with silica gel phosphor 3 to form a white light WLED Illuminant; use high-strength industrial plastic PC with high light transmittance to design and make a thin (0.2mm) equal-thick hemispherical shell 5 by H=R-0.577w-0.33h relational formula; adopt the same light transmittance as PC ( no 1 =1.40) of highly transparent silicone gel is filled into the PC shell to form a silicone hemispherical lens 4; the silicone hemispherical lens 4 is centered and packaged above the fluorescent powder to form a non-reflective high light output unit WLED light source, and the capacity of each unit WLED light source is combined to expand Become a high-power WLED light source.

[0057] FIG. 6 is a schematic diagram of a multi-unit WLED expansion structure. A plurality of unit WLED ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com