Accurate aluminum cell baiting feedback information control method

A feedback information, aluminum electrolytic cell technology, applied in the field of accurate feeding feedback information control of aluminum electrolytic cells, can solve problems such as changing strategies, poor control effects, and reduced alumina concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

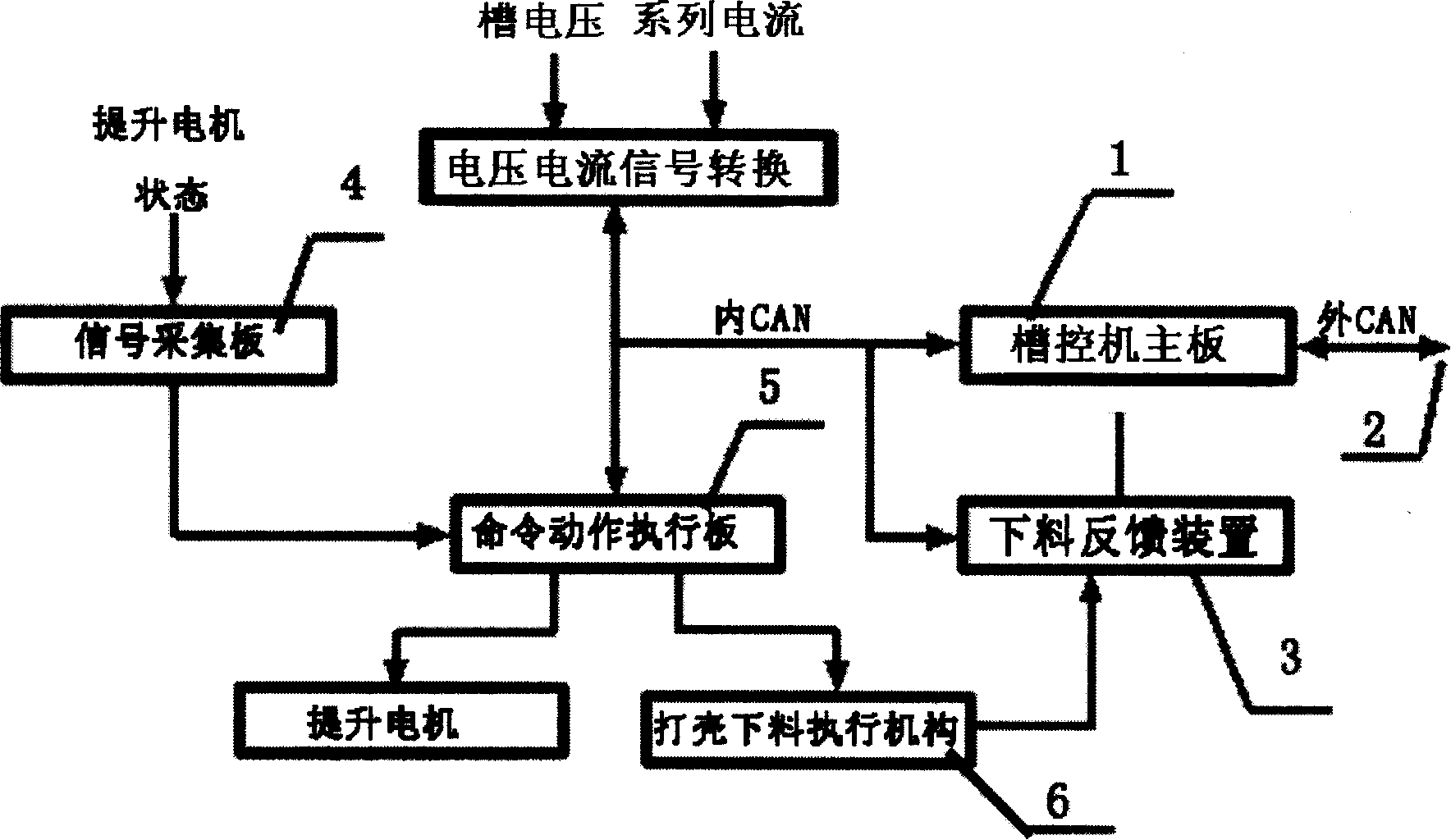

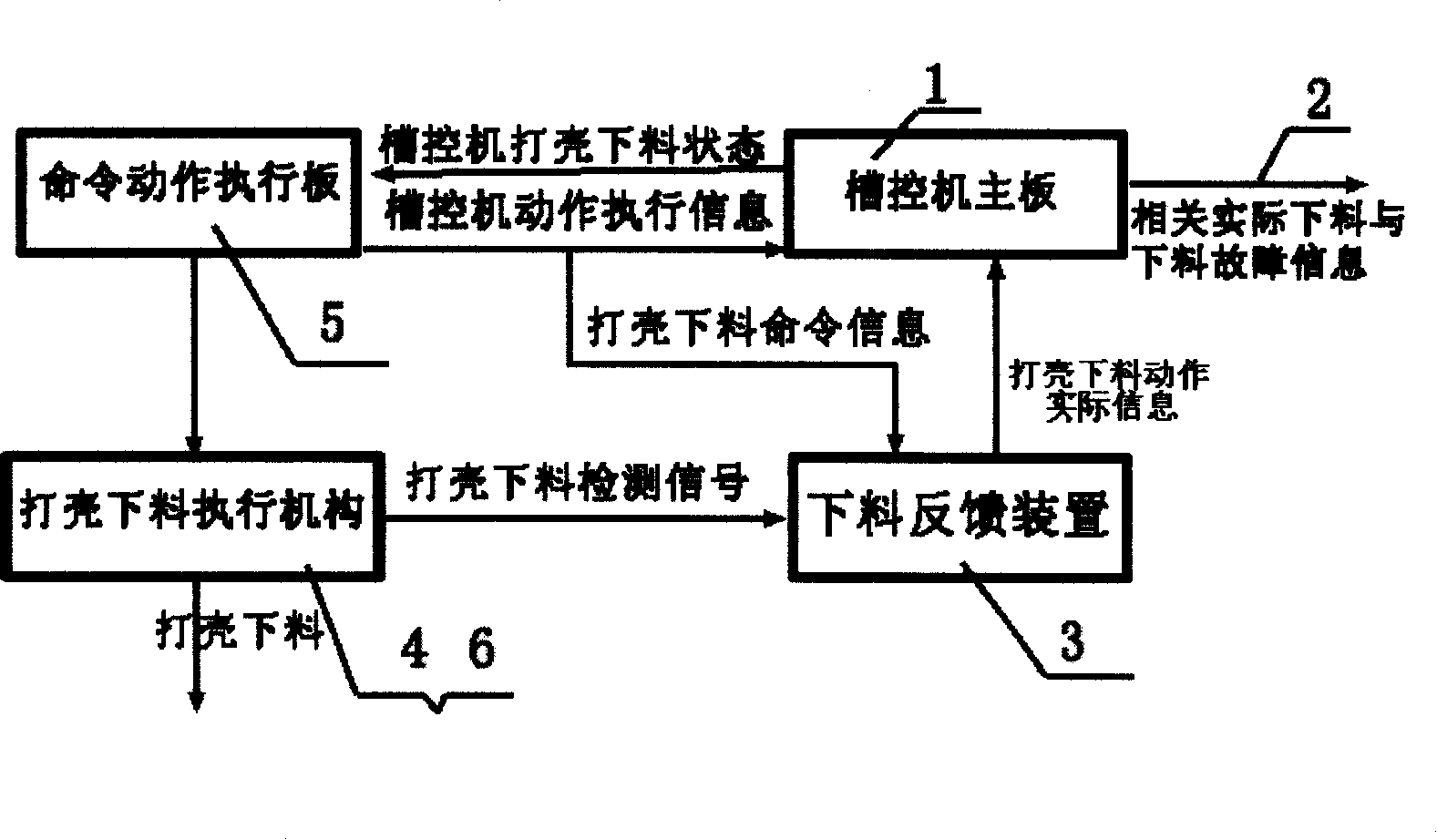

[0021] Such as figure 1 As shown, the slot control machine 1 and the upper computer 2 are connected by CAN bus communication mode; the output terminal of the signal acquisition board 4 is connected with the input end of the blanking feedback device 3 by a CAN communication bus, and the output terminal of the slot control machine 1 The input end of the blanking feedback device 3 is connected with the CAN communication bus, and the output end of the blanking feedback device 3 is connected with the input end of the main board of the slot control machine 1 through the CAN communication bus.

[0022] What the present invention uses is YFC-99 tank control machine, and it adopts the multi-CPU modular design of network system, and each module carries out certain specific function, as signal acquisition board 4, is used for detecting the working state of electrolyzer hoisting motor Signal, feedback the signal to the command action execution board 6; the voltage and current signal conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com