Method for producing biomass polyalcohol with plants stalk liquescence

A technology for biomass polyol and plant straw, which is applied in the field of liquefying plant straw to prepare biomass polyol, can solve the problems of unsatisfactory liquefaction effect, difficult access of liquefaction reagents, damage to tissue structure, etc., and achieves reduction of liquefaction conditions and improvement of liquefaction effect. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Spray water on the sawdust, the amount of water spray is 30%, put the evenly mixed wet material into the steam explosion tank from the feed port, close the steam explosion tank, feed steam from the steam pipeline, observe the pressure gauge, when the pressure is Stop feeding steam at 1.7MPa, and after maintaining the pressure for 4 minutes, close the steam pipeline, open the discharge nozzle valve, and instantly burst the material in the tank, and dry it to obtain steam-exploded sawdust;

[0025] Put the steam-exploded wood chips into a reaction tank, add polyethylene glycol and sulfuric acid to make the liquid-solid mass ratio 5:1, and stir and react for 2 hours at a temperature of 130°C to obtain steam-exploded wood chips. Liquefaction product - biomass polyol;

[0026] The added sulfuric acid is concentrated sulfuric acid, and its add-on is the % of polyhydric alcohol adding weight;

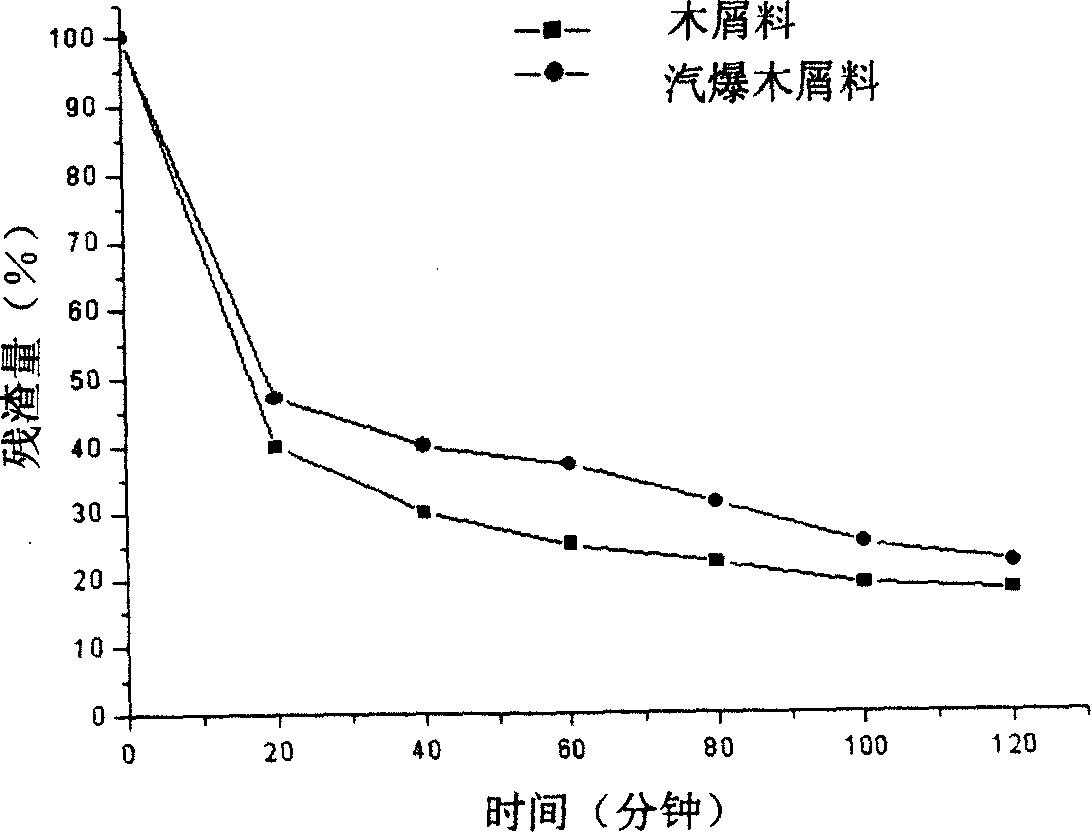

[0027] Its liquefaction effect is expressed by the residue rate, from figure 1 It...

Embodiment 2

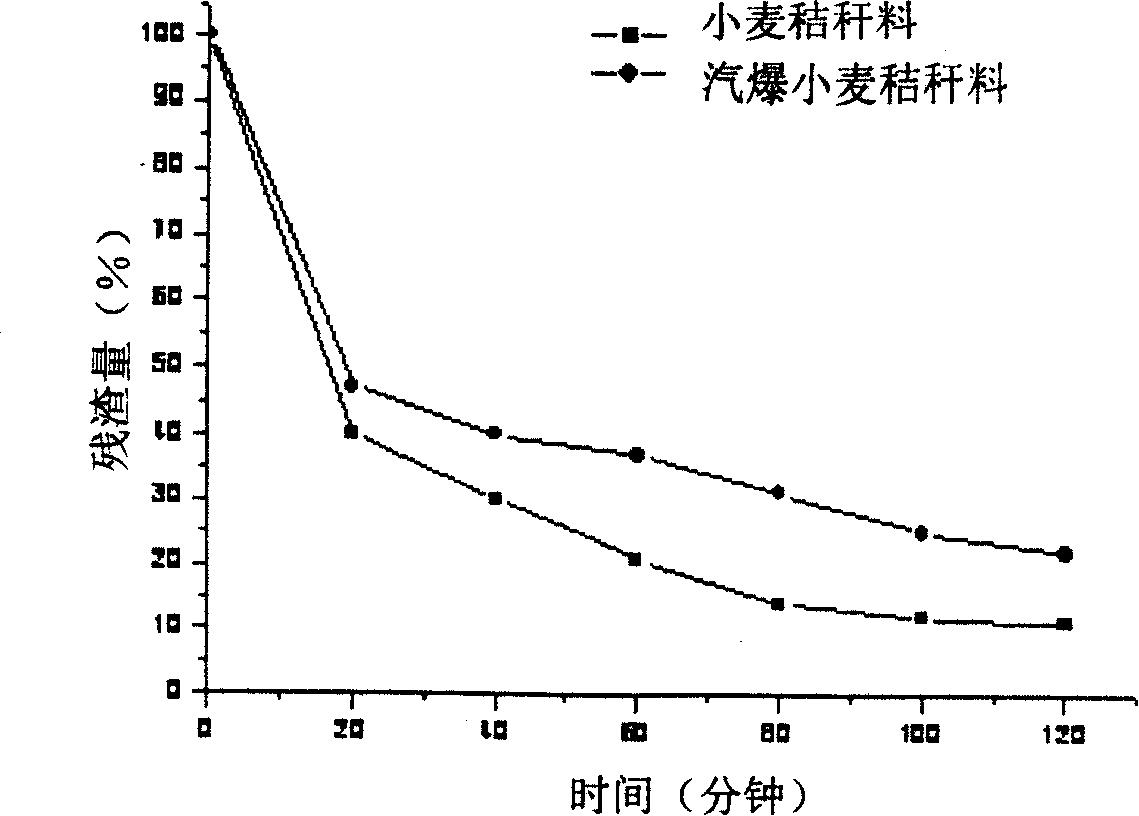

[0029] Spray water on wheat (or rice straw) stalks, the amount of water spray is 30%, put the evenly mixed wet material into the steam explosion tank from the feed port, close the steam explosion tank, feed steam from the steam pipeline, and observe Pressure gauge, when the pressure is 1.6MPa, stop feeding steam. After maintaining the pressure for 4 minutes, close the steam pipeline, open the outlet valve, and instantly burst the material in the tank, and dry the steam-exploded wheat (or straw) ) Straw material.

[0030] The steam-exploded wheat (rice straw) stalk material that has been steam-exploded is put into a reaction tank, and ethylene glycol and sulfuric acid are added so that the liquid-solid mass ratio is 2:1 (or 3:1). At a temperature of 110°C, Stirring and reacting for 1 hour, the steam-exploded wheat (rice straw) stalk liquefaction product-biomass polyol was obtained;

[0031] The added sulfuric acid is concentrated sulfuric acid, and its add-on is 3% of polyhydr...

Embodiment 3

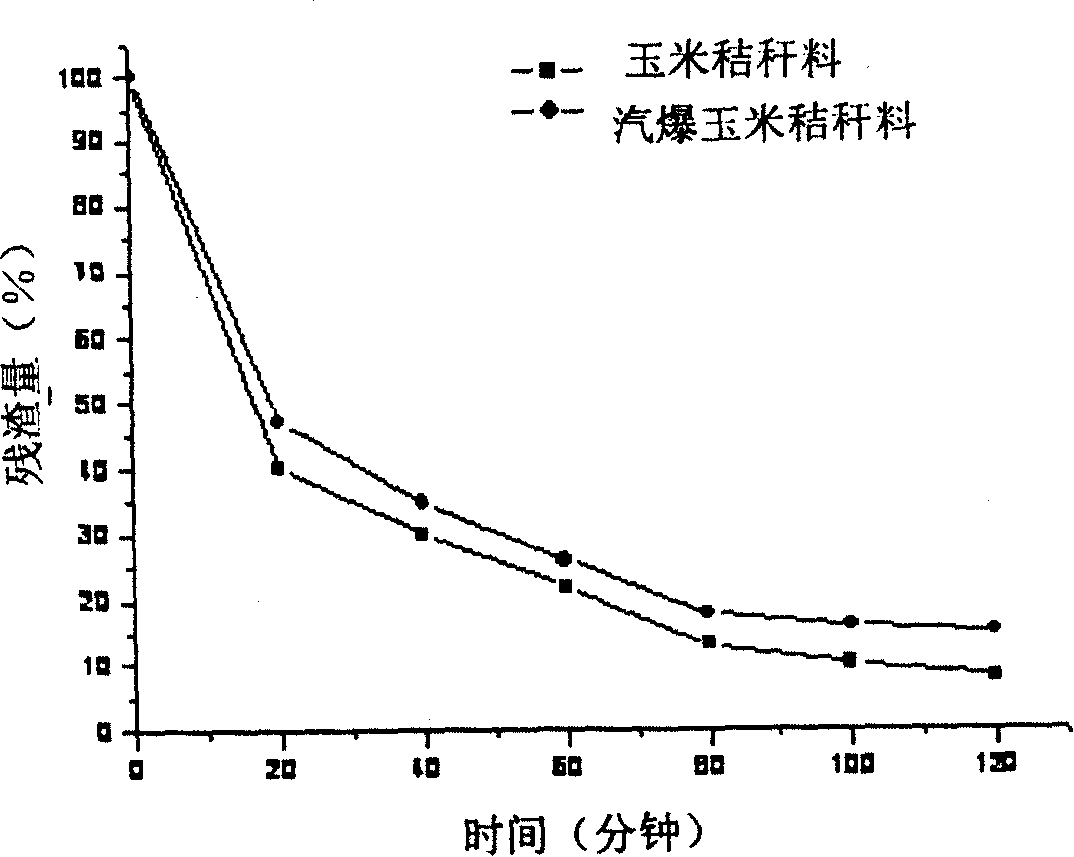

[0034] Spray water on corn (or sorghum) stalks, the amount of water spray is 30%, put the evenly mixed wet material into the steam explosion tank from the feed port, close the steam explosion tank, feed steam from the steam pipeline, and observe the pressure When the pressure is 1.65MPa, stop feeding steam. After maintaining the pressure for 4 minutes, close the steam pipeline, open the outlet valve, and instantly burst the material in the tank, and dry it to obtain steam-exploded corn (or sorghum). Straw material.

[0035] The steam-exploded corn (or sorghum) straw material is directly used for liquefaction,

[0036] Put the steam-exploded corn (or sorghum) straw material into the reaction tank, add polyethylene glycol and sulfuric acid to make the liquid-solid mass ratio 4:1, and stir for 1.5 hours at a temperature of 120°C , to obtain steam-exploded corn (or sorghum) stalk liquefaction product-biomass polyol;

[0037] The added sulfuric acid is concentrated sulfuric acid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com