C*í½C*alkane isomerization catalyst and isomerization process

A technology of alkane isomerization and catalyst, applied in the field of alkane isomerization, can solve the problem of isomerization selectivity reduction and achieve the effect of high isomerization selectivity, high activity and low cracking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

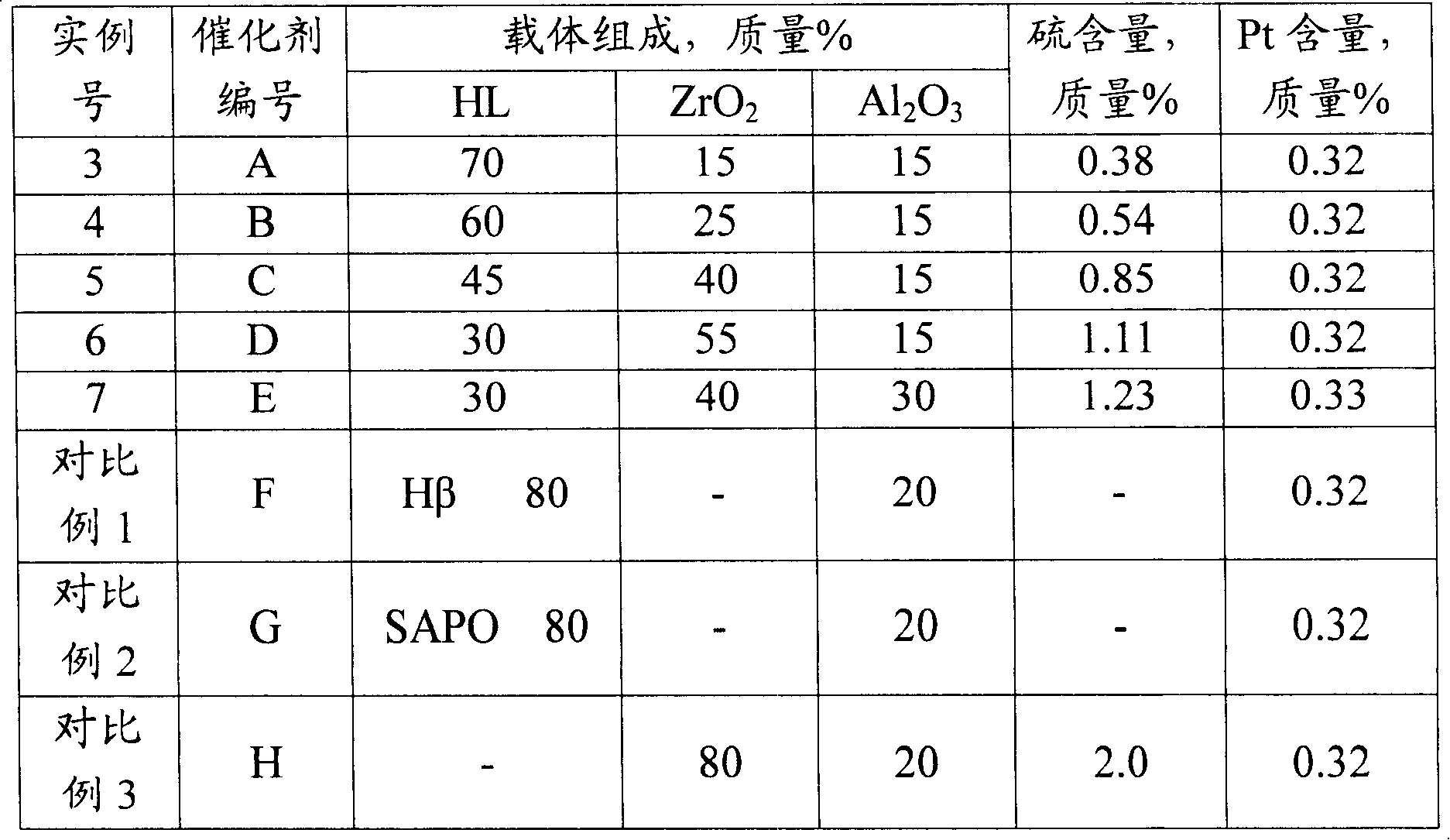

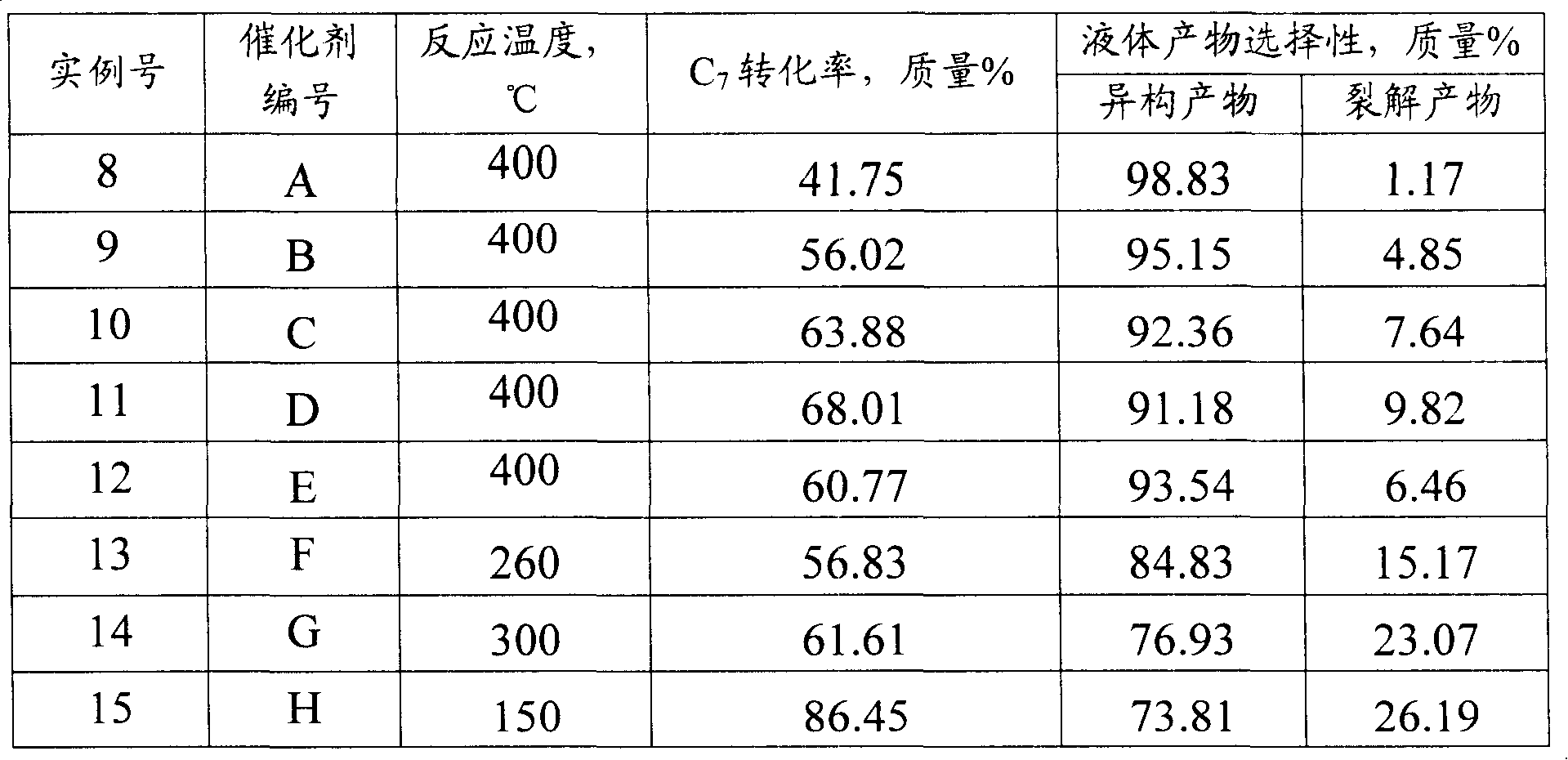

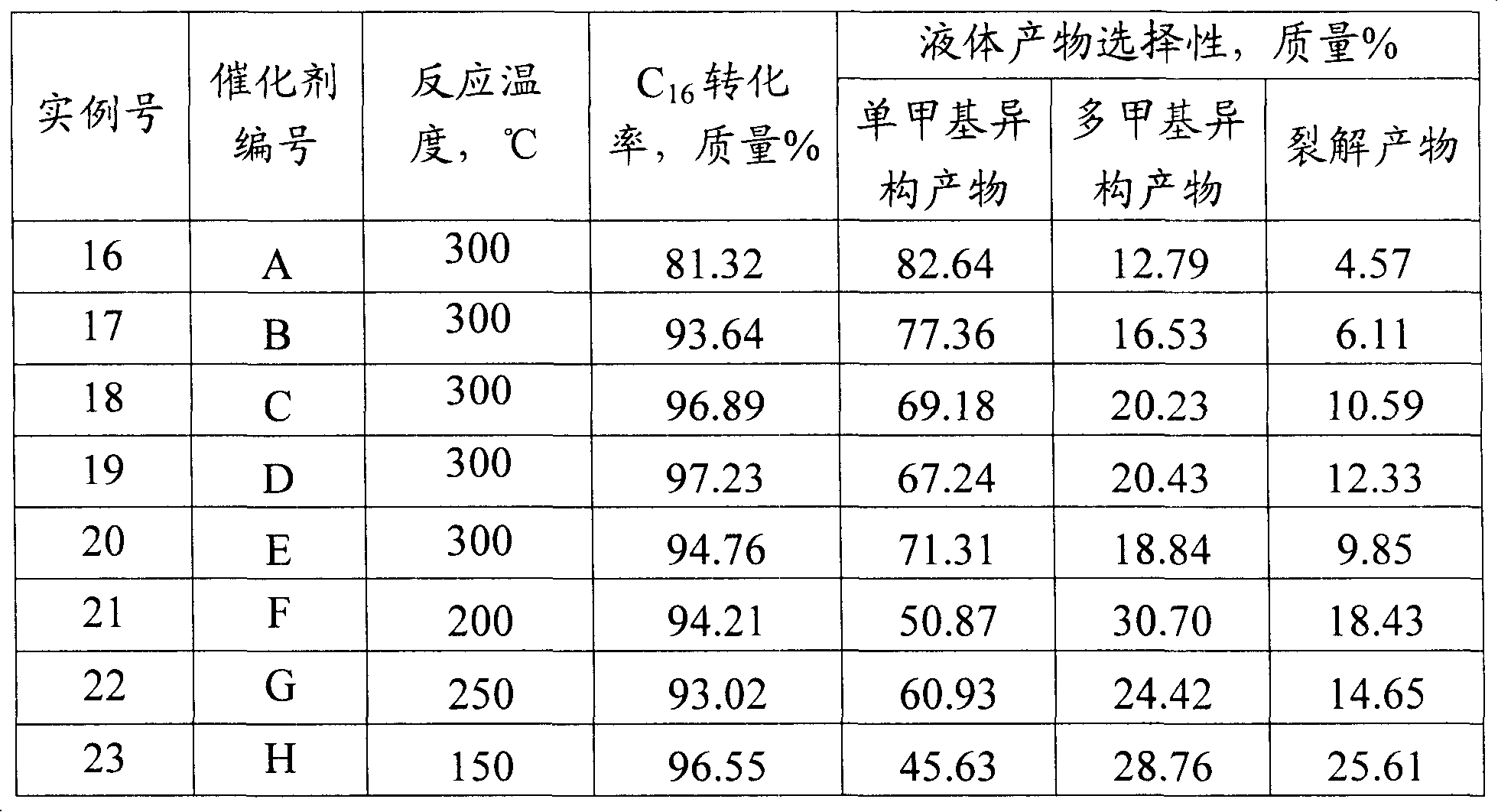

Examples

preparation example Construction

[0013] The preparation method of the catalyst provided by the present invention includes mixing L zeolite, hydrated zirconia and binder, forming a composite carrier through molding, impregnating the composite carrier with dilute sulfuric acid solution, drying the compound carrier containing Group VIII metal The solution is impregnated, then dried and fired.

[0014] The L zeolite used to prepare the composite carrier in the method is preferably hydrogen type, and the method for preparing hydrogen type L zeolite is to use 0.1 to 5.0 moles / liter of ammonium salt solution, preferably ammonium chloride solution, at 80 to 105 °C for L zeolite. For ion exchange, the number of exchanges can be one to multiple times, preferably 1 to 5 times, and the time for each exchange is preferably 0.5 to 10 hours.

[0015] When preparing the composite carrier, mix L zeolite, hydrated zirconia and binder, add a small amount of peptizer, and shape it. The molding method is preferably extrusion mold...

example 1

[0022] Preparation of Hydrogen Form L Zeolite.

[0023] Get 100 grams of silica / alumina molar ratio to be 5.1, Na 2 O content is 0.01% by mass, K 2 O content is the L zeolite of 23.4 mass % (according to the disclosed hydrothermal method synthesis of patent US 3216789), with 300 milliliters of concentration be the NH of 1 mol / liter 4 The Cl solution was treated at 92°C for 3 hours for ion exchange, then filtered and washed with deionized water until the filtrate contained no Cl - , dried at 120°C to make SiO 2 / Al 2 o 3 Hydrogen-form L zeolite HL with a molar ratio of 5.5 (determined by fluorescence spectrometry).

example 2

[0025] Preparation of hydrated zirconia.

[0026] Zirconium oxychloride (ZrOCl 2 ·8H 2 (0) be made into 5 mass % aqueous solution, add dropwise 25 mass % concentrated ammonia water to solution pH value is 8.5, all precipitation and solution are transferred in the autoclave, 120 ℃ of crystallization 24 hours, precipitation washing and filtering to filtrate is Neutral and no detectable Cl -1 , Dry at 110°C for 24 hours to produce hydrated zirconia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com