Linear guide unit with length measuring system

A guide unit, length measurement technology, applied in the direction of bearing/suspension, mechanical clearance measurement, bearing components, etc. of the movable parts of the measuring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

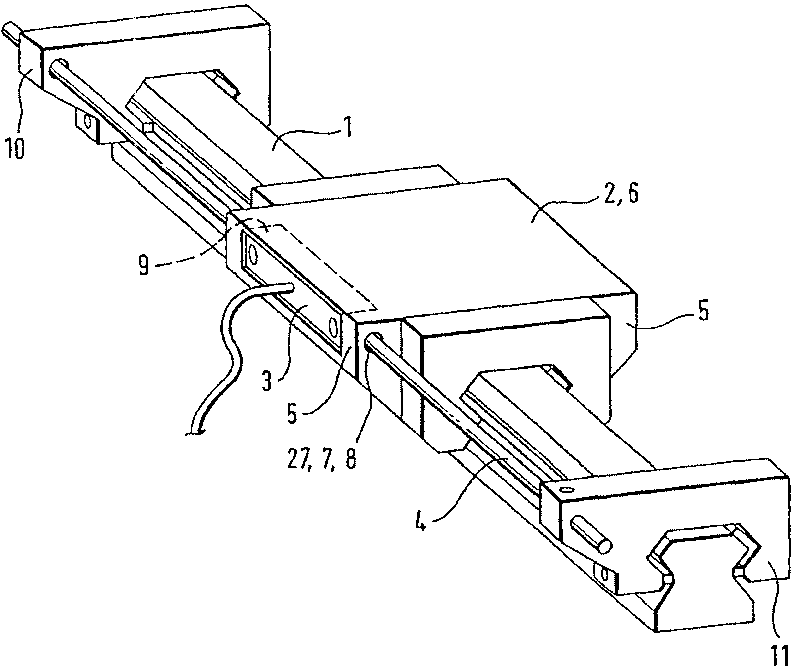

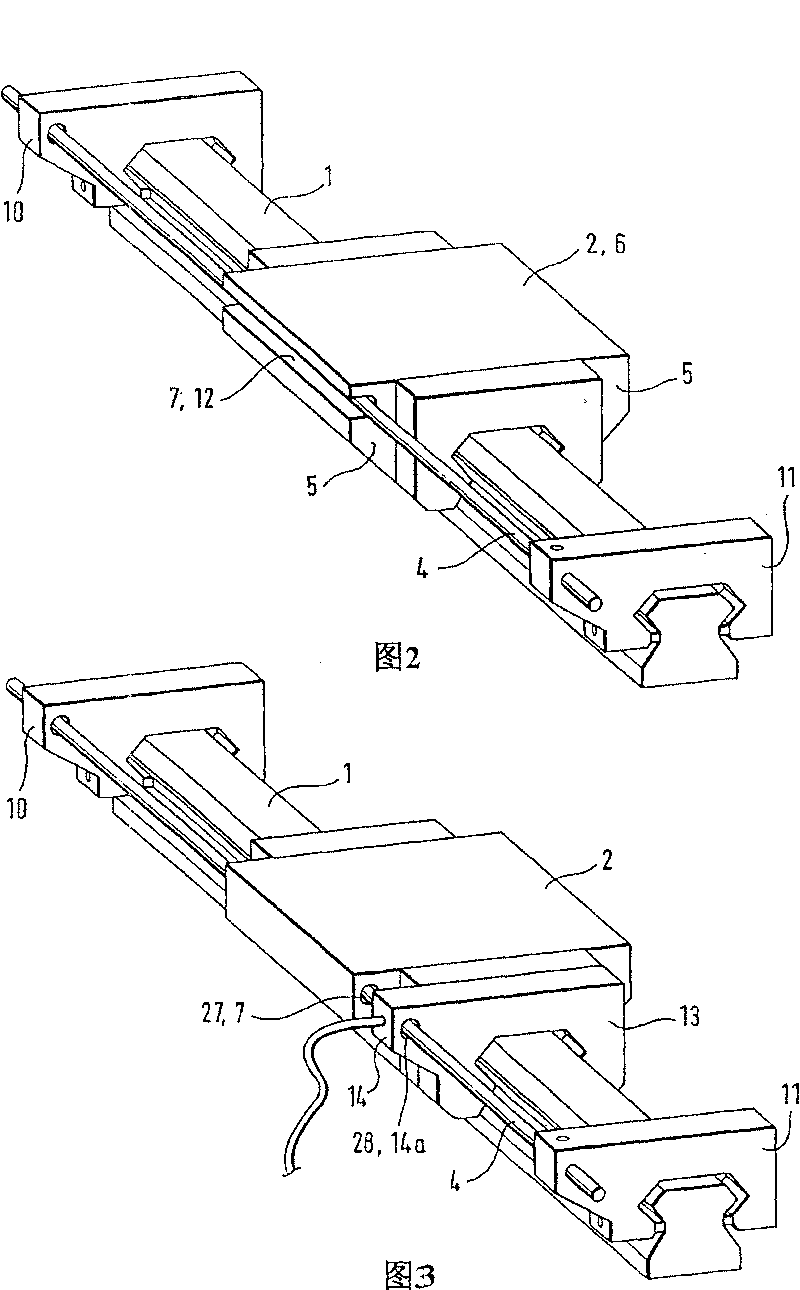

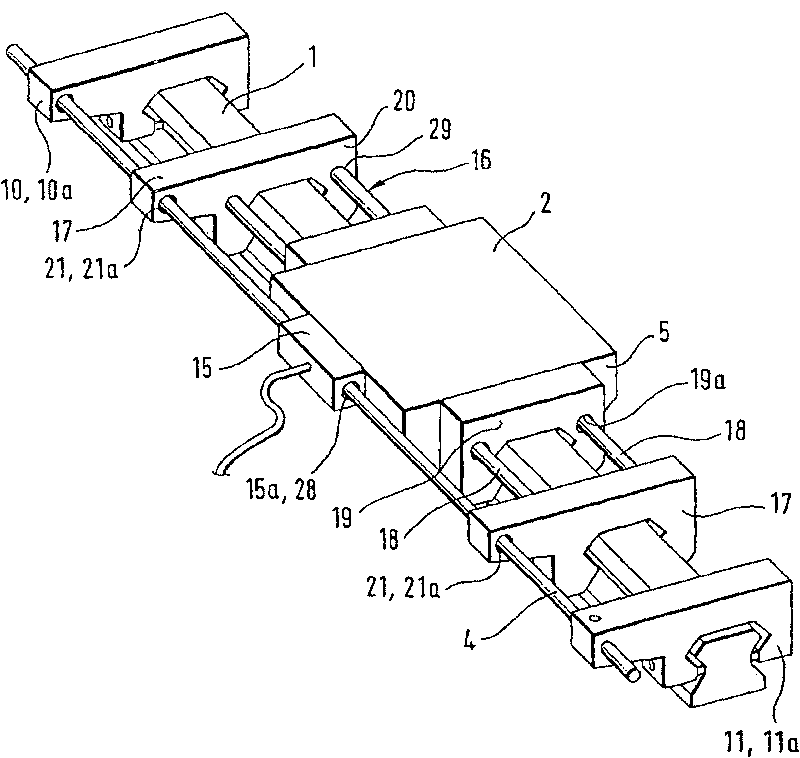

[0019] figure 1 The shown linear guide unit according to the invention has a guide frame 2 guided longitudinally on a guide rail 1 . Rolling bodies, not shown further here, roll under load on the running surfaces of the guide rails and guide frames in a known manner. The rolling surfaces define a load channel. The rolling element rings are arranged in endless rolling element channels, wherein each rolling element channel has the already mentioned load channel, return channel and two reversing channels endlessly connecting the return channel and the load channel. The reversing channel and the return channel are completely arranged in the guide frame 2 .

[0020] The linear guide unit according to the invention also contains a length measuring system which has a measuring head 3 and a measuring tool 4 . The length measuring system works on the inductive principle. The measuring device 4 is designed as a round rod. The metering tool 4 is formed of a stainless steel tube in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com