No empty hole installation method for installing electronic components

A technology for electronic components and installation methods, which is applied in the direction of assembling printed circuits, electrical components, and electrical components with electrical components, and can solve problems such as crushing, difficulty in filling hollow areas, and lack of support at the bottom of electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

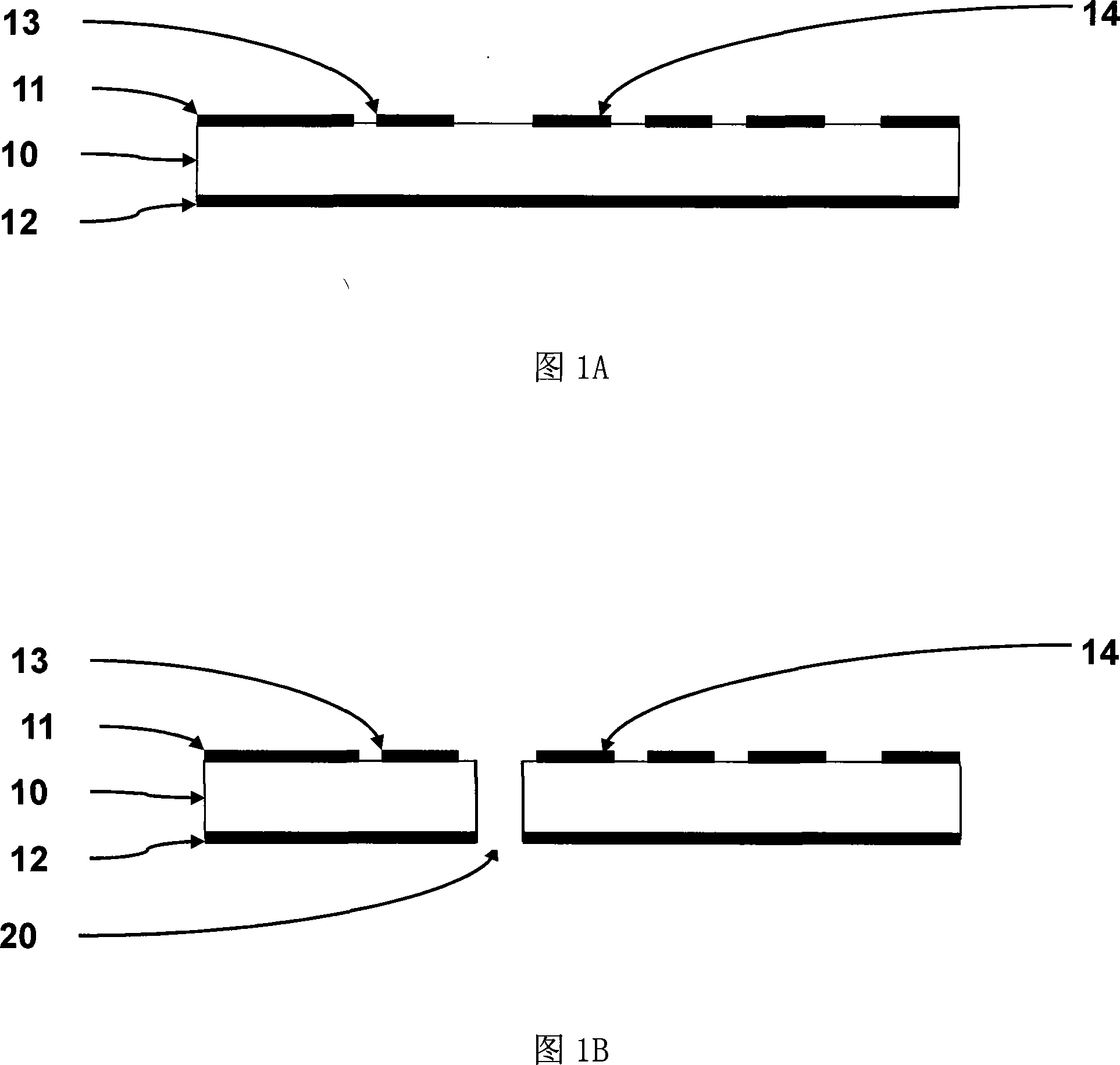

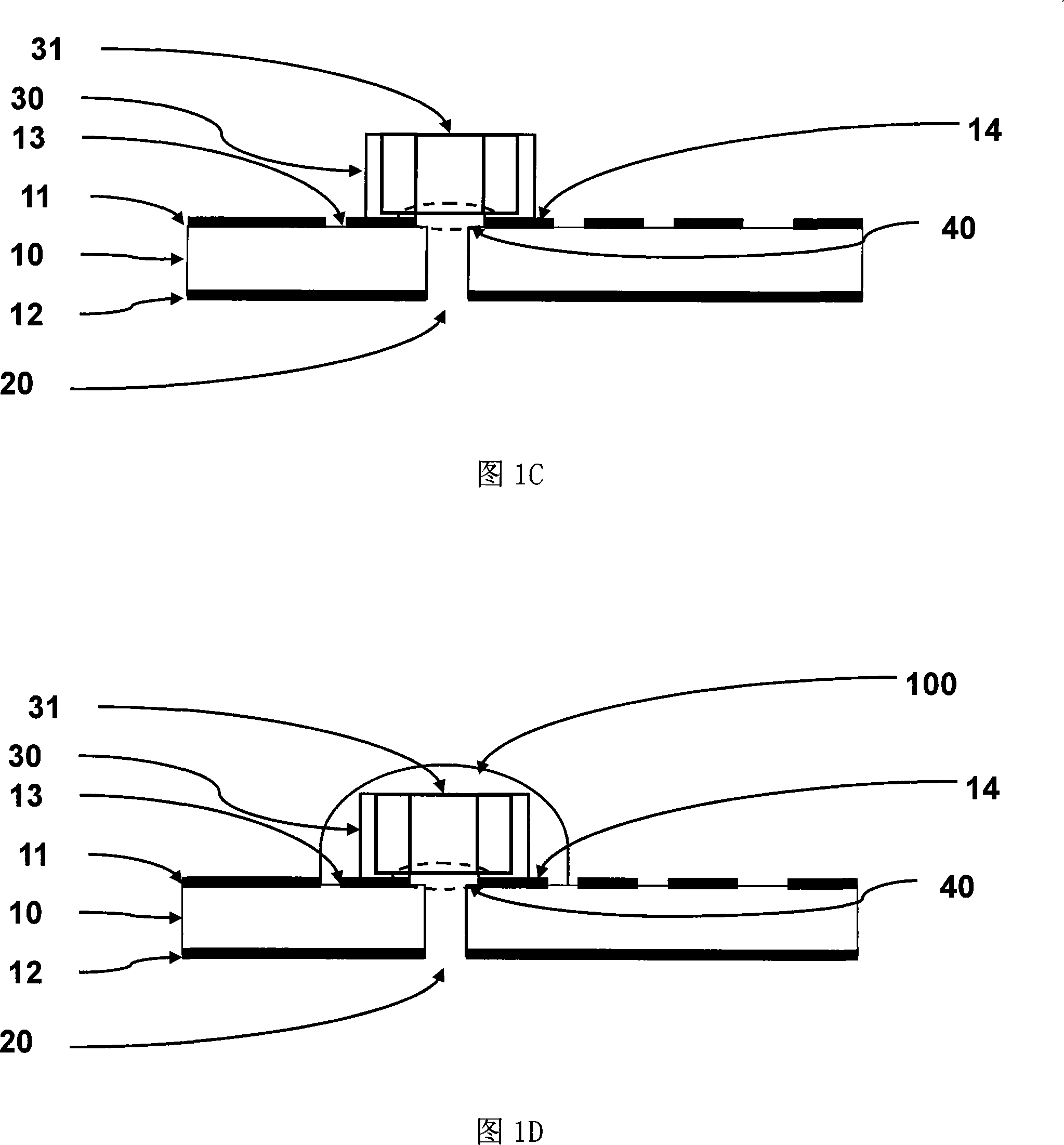

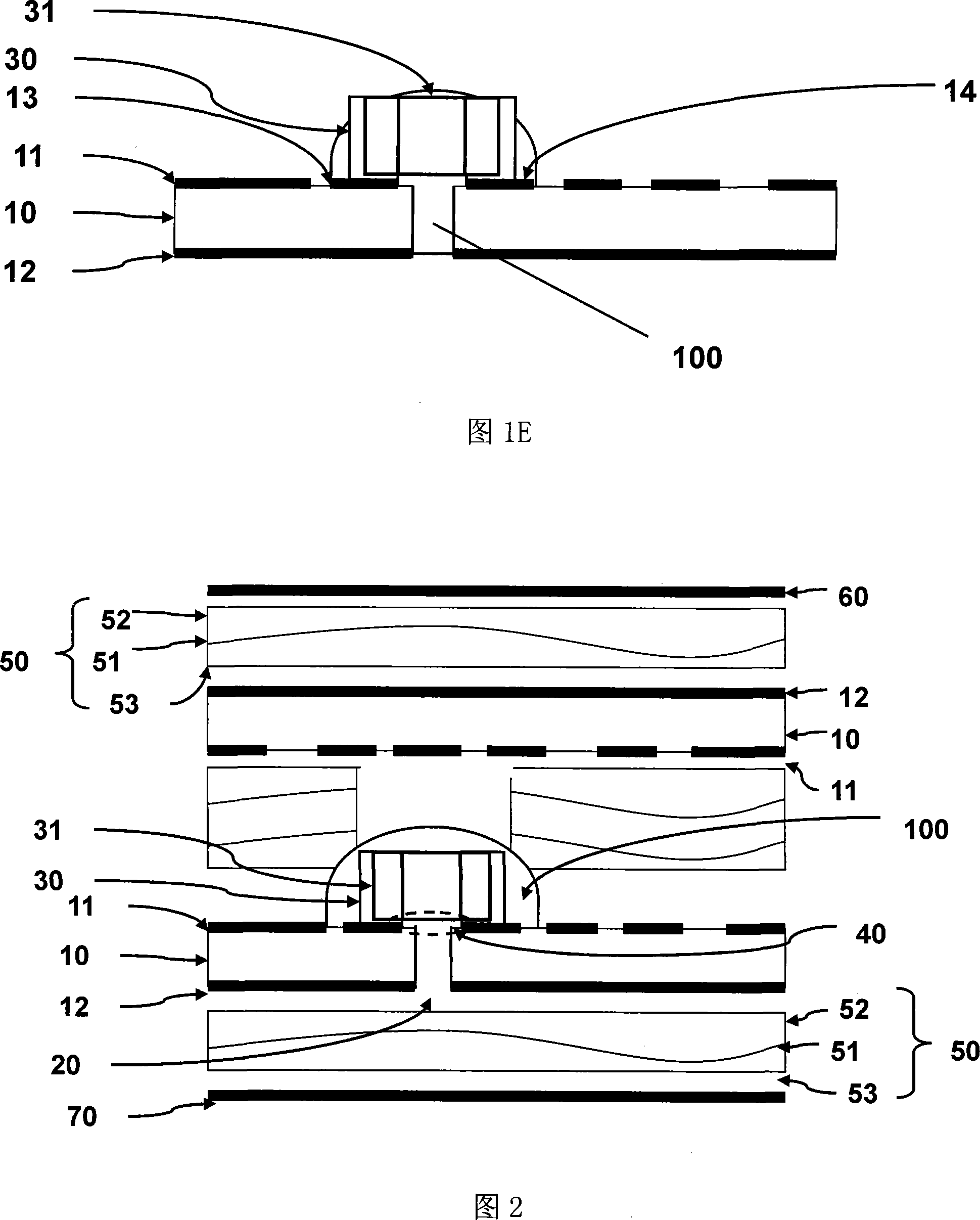

[0020] Please refer to FIGS. 1A to 1E. FIGS. 1A to 1E are schematic diagrams of a first implementation of a cavity-free mounting method for mounting electronic components of the present invention. As shown in Figure 1A, in order to make the circuit board (including the substrate 10, the circuit layer 11, and the power / ground layer 12) electrically connect to the electronic components 31 (such as passive components, capacitors, resistors or diodes), the circuit board A set of connection points will be made first. The set of connection points can be composed of two connection points 13,14.

[0021] To put it simply, as shown in FIG. 1D, in order to provide complete support for the electronic component 31, the insulating material 100 is introduced through the electronic component 31 to the air guide hole 20 underneath the electronic component 31 by vacuum attraction, and filled with The cavity area 40 between the component 31 and a set of connection points 13 and 14. It should be not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com