Etching device of organic EL display panel and its method

A technology for electroluminescence display and etching equipment, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of difficult repair, complicated equipment, easy damage and contamination, etc., to shorten the etching time and improve the etching rate. effect, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

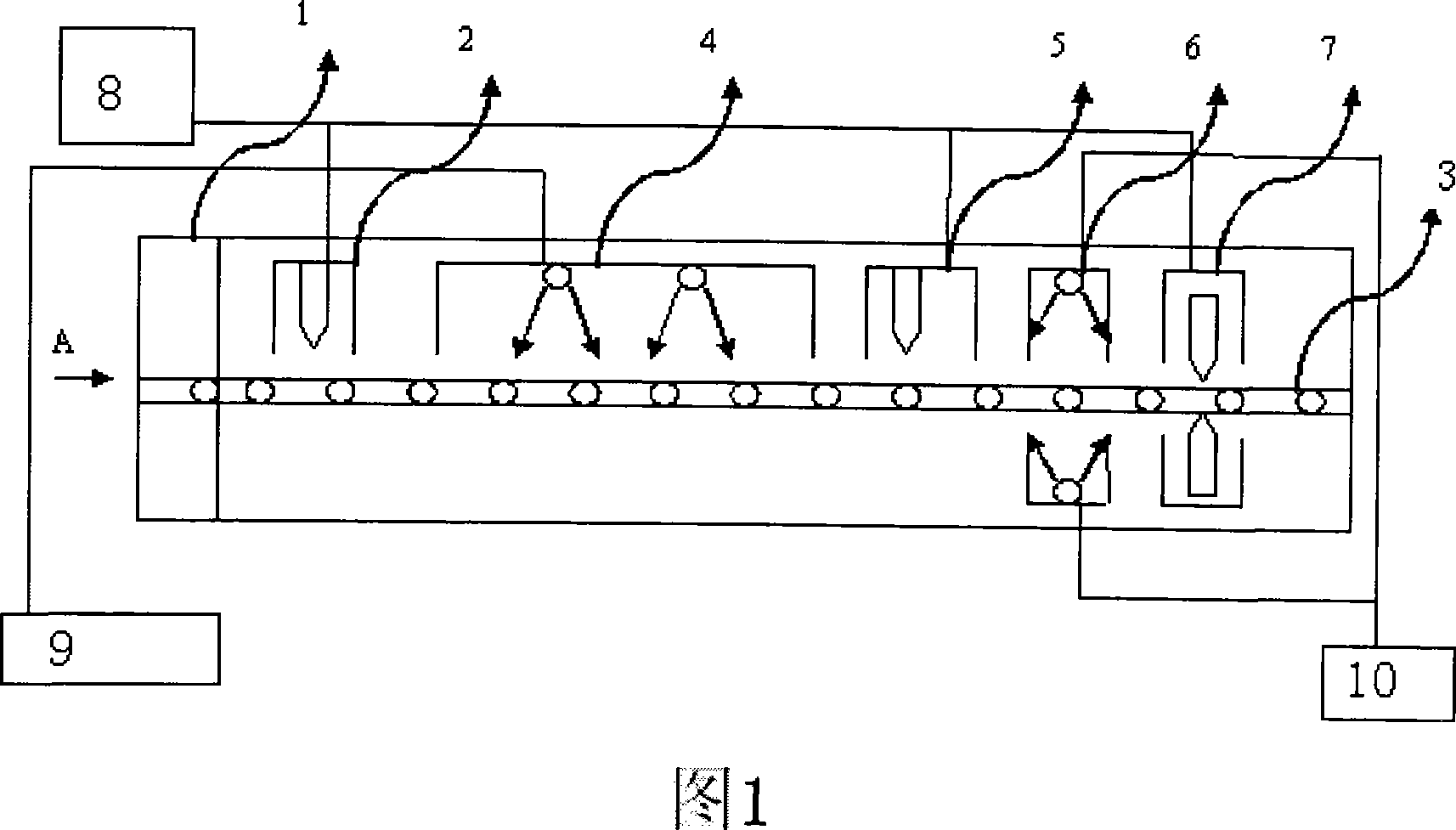

[0022] As shown in Figure 1, an organic electroluminescent display panel etching device provided by an embodiment of the present invention has a chip opening 1 from the input end to the output end of the substrate, and an air knife is provided inside to isolate the outside air and prevent the Transition unit 2 for acid gas overflow, etching unit 4 for etching substrates, liquid cutting unit 5 with air knife for blowing off etching solution, water washing unit 6 for washing substrates, and cleaning unit for drying and cleaning substrates Air knife drying unit 7, described each unit is connected by the roller conveying unit 3 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com