Dry quenching coke high and low voltage generation system possessing steam pressure control device

A pressure control and power generation system technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as continuous jumping, obvious pressure difference, steam turbine jumping, etc., and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

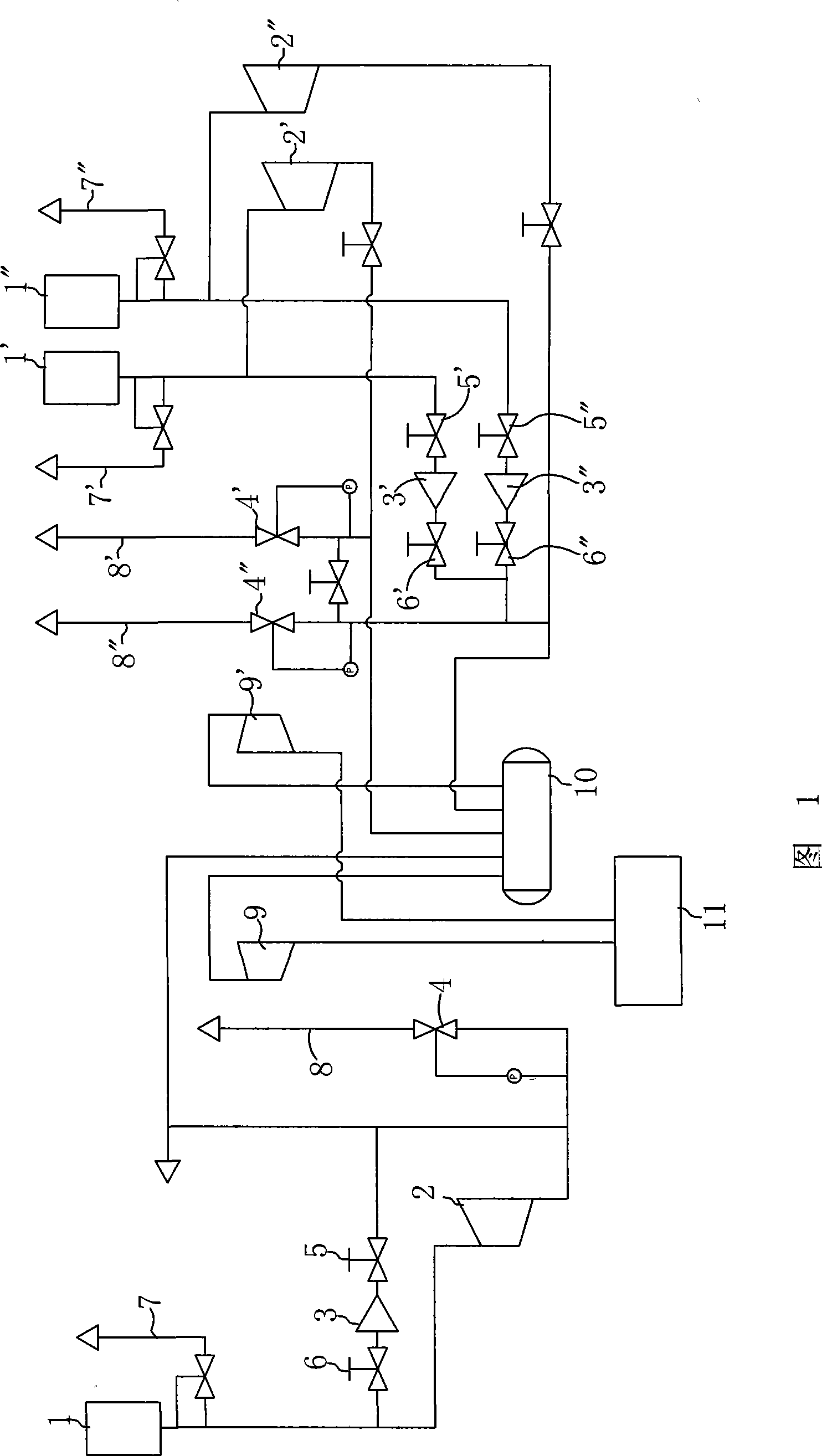

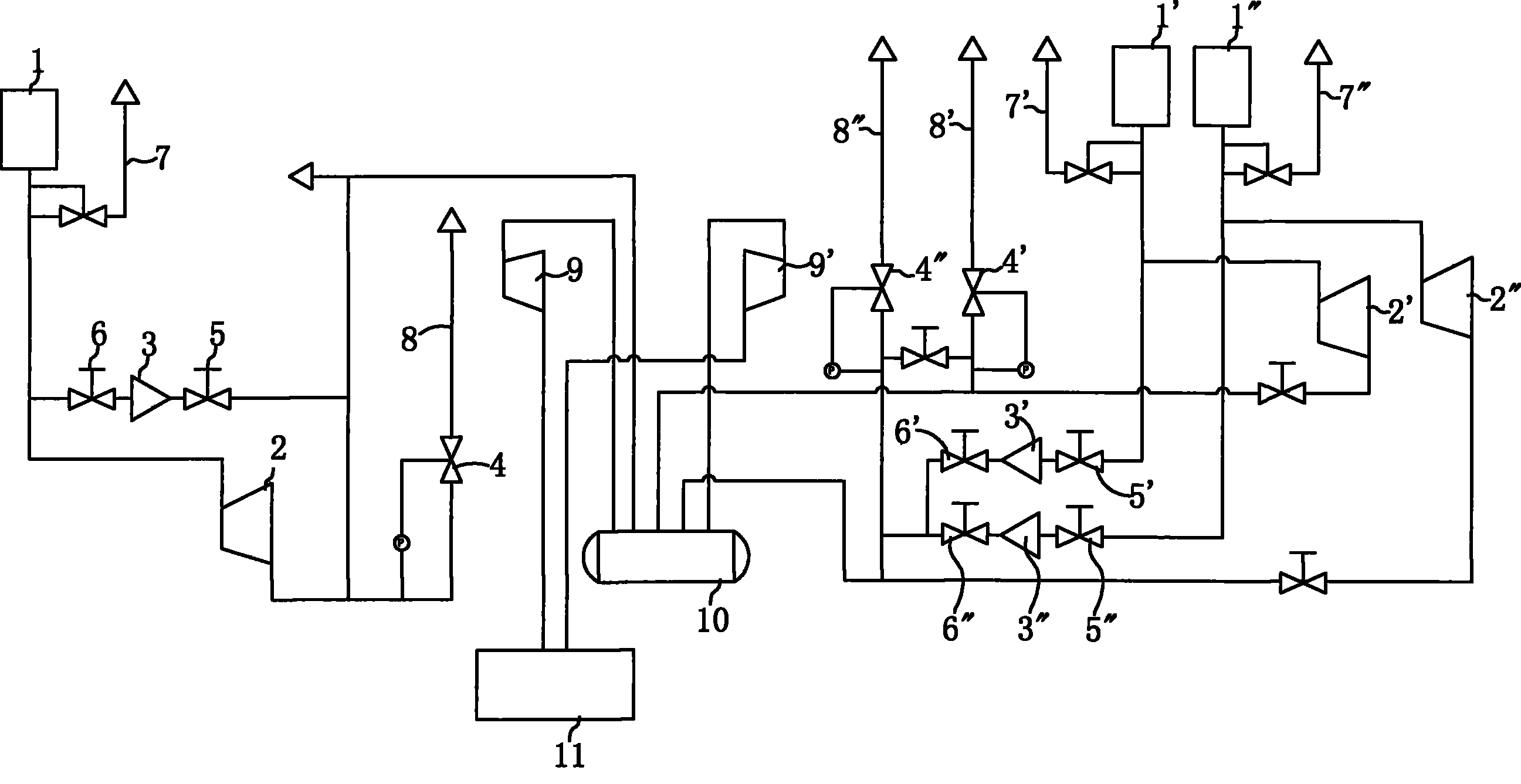

[0022] As shown in Figure 1, the coke CDQ high and low pressure power generation system with steam pressure control device includes three steam boilers 1, 1' and 1", and the steam pipelines of the three steam boilers are connected to the outlet ports of the high pressure steam turbine respectively. There are high-pressure steam release pipes 7, 7', 7" and high-pressure steam release valves. Each steam boiler is connected with a back-pressure high-pressure steam turbine through a steam pipeline, and the three back-pressure high-pressure steam turbines 2, 2' and 2" are respectively installed in parallel with a release device, and the release device is manually adjusted by the release valve 4, 4' , 4", automatic pressure relief valve 3, 3', 3", composed of relief ports, steam pipelines are connected at both ends of each high-pressure steam turbine, and the steam pipelines at both ends of the high-pressure steam turbines are parallelly connected with relief pipes. After the automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com