Method for producing methyl isopropyl ketone

A technology of methyl isopropyl ketone and production method, which is applied in the direction of condensation preparation of carbonyl compounds, etc., can solve the problems of easy loss of phosphoric acid, easy sludging of catalysts, and inability to use catalysts for a long period of time, so as to improve stability and prolong service life. , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

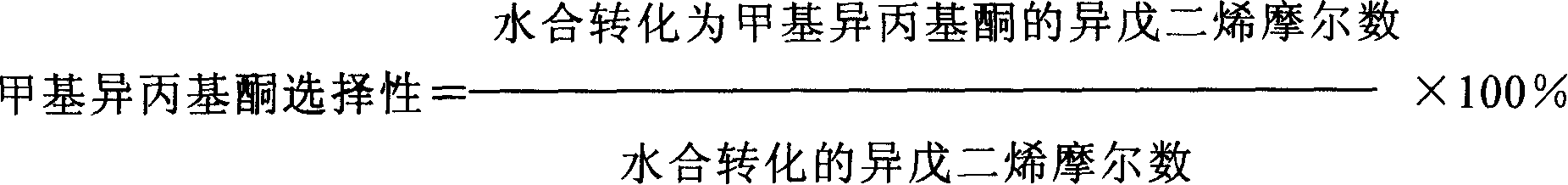

Examples

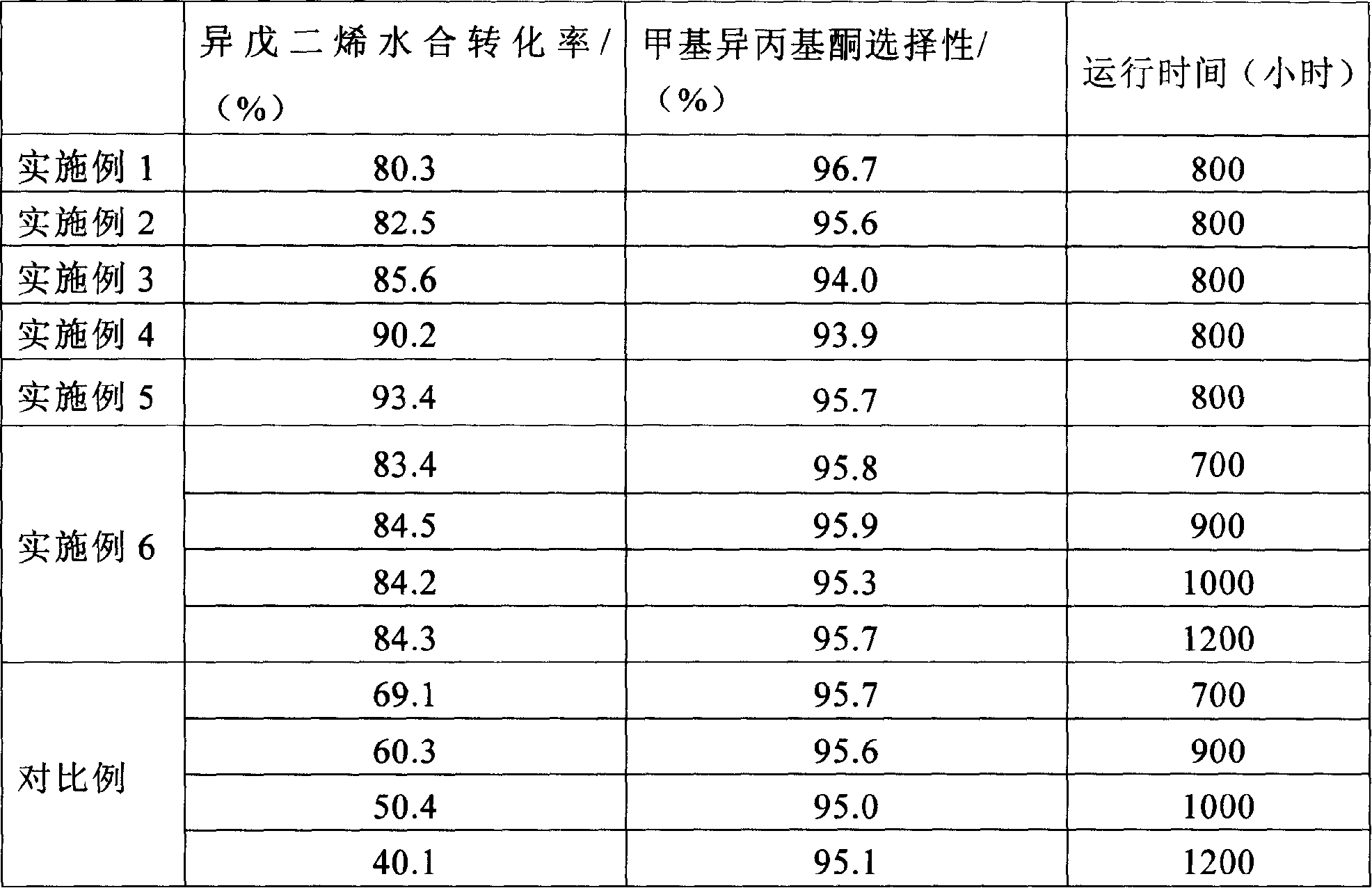

Embodiment 1~6

[0025] The hydration reactor is a stainless steel tubular reactor with a diameter of φ25mm×1000mm, and the reaction tubes are filled with H with a diameter of 5mm×8mm. 3 PO 4 -B / diatomite catalyst 100 ml, the bottom of the reactor is filled with inert ceramic balls. H in the catalyst 3 PO 4 The content is 50%-80%, the boron content is 4-9%, and the rest is carrier.

[0026] After water and isoprene are vaporized and mixed separately, preheated to the set temperature, and enter the H 3 PO 4 -B / diatomaceous earth catalyst bed for hydration reaction. The reaction temperature is 180-300°C, the molar ratio of water and isoprene is 4.0-8.0, and the space velocity LHSV is 0.1-0.5h -1 , The reaction pressure is normal pressure ~ 0.3MPa. The reaction pressure was regulated by a pressure controller at the outlet of the reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com