Process for purifying exhaust gases and apparatus for purifying exhaust gases

A technology of exhaust flow and supply device, which is applied to exhaust devices, chemical instruments and methods, separation methods, etc., can solve the problem of difficult to use ozone to remove PMs, etc., and achieve the effect of effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

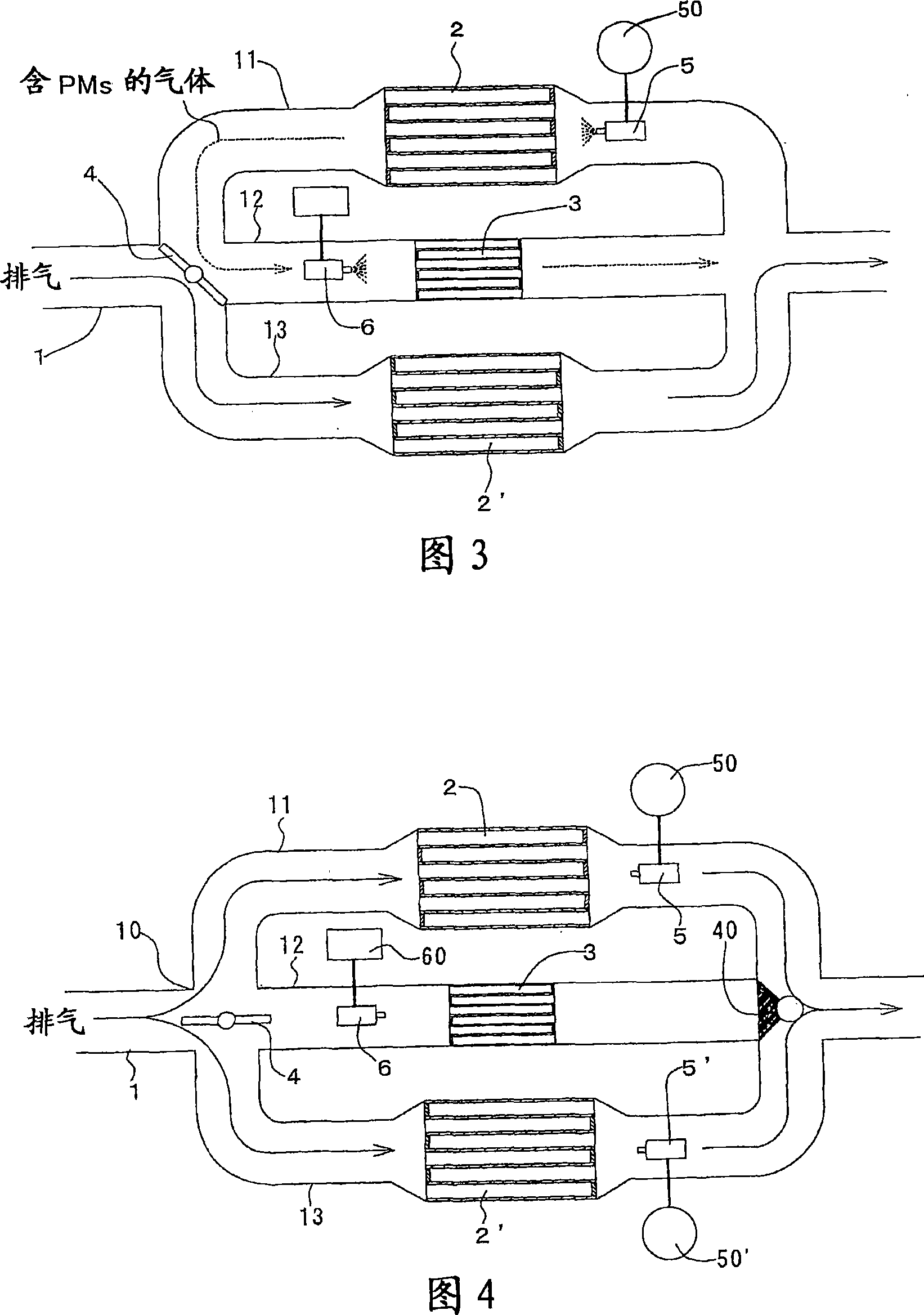

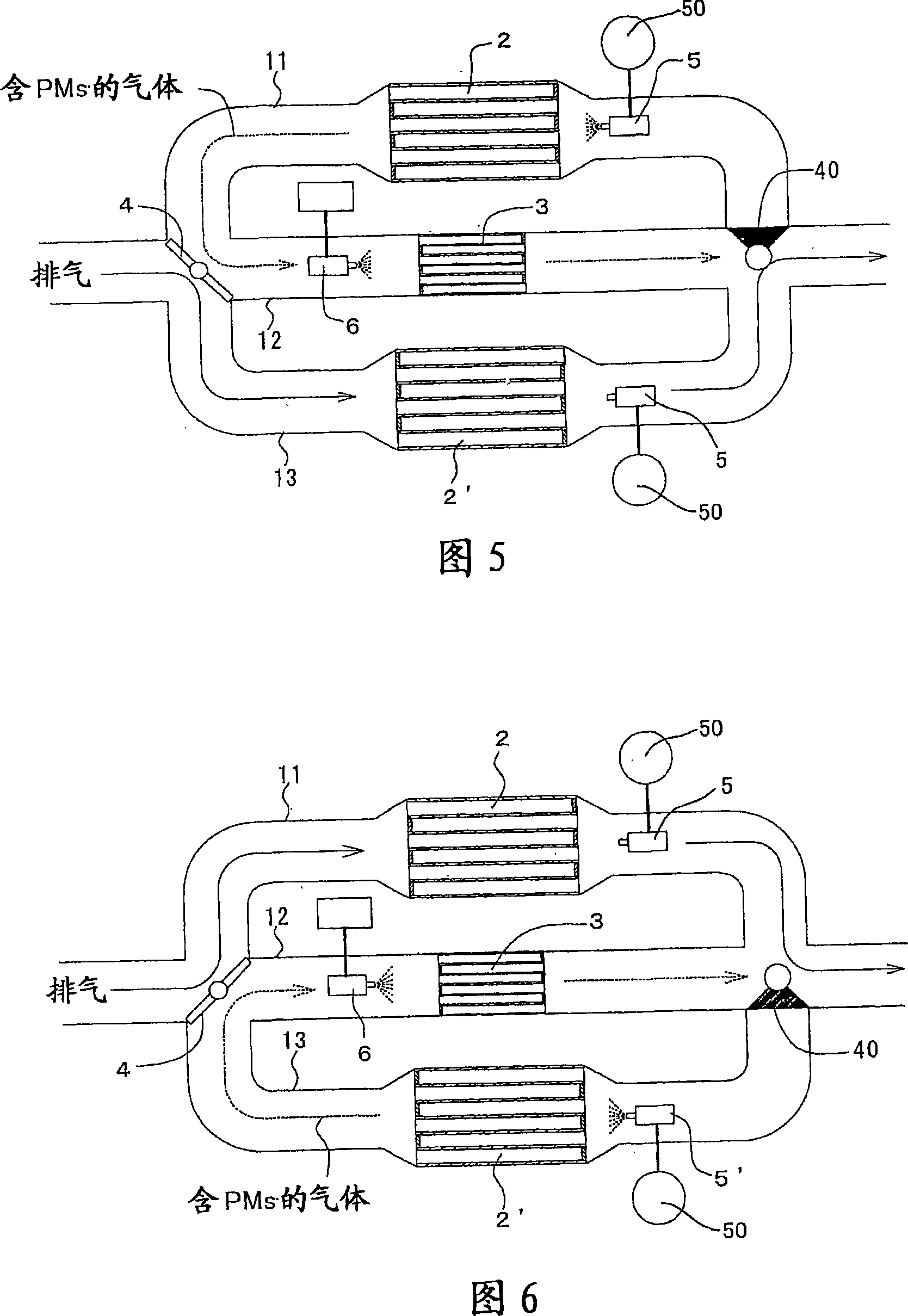

[0035] Having generally illustrated the invention, it is further described by reference to specific preferred embodiments which are provided herein for purposes of illustration only and are not intended to limit the scope of the appended claims.

[0036]According to the exhaust purification method of the present invention, in the step of trapping PMs, PMs are firstly trapped with a filter. As for the exhaust gas, there may be exemplary PMs-containing exhaust gas such as exhaust gas emitted from a diesel engine.

[0037] The filter traps PMs by filtering only the gas components in the exhaust gas. For example, the filter can consist of metal foam or heat-resistant non-woven fabric. Alternatively, filters can be made of heat-resistant ceramics such as cordierite and silicon carbide. As one of such filters, a wall flow structure DPF has been known. The wall flow structure DPF includes: an inlet unit inserted on the downstream side of the exhaust flow; an outlet unit located ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com