Reverse opening type separable end stop of slide fastener

A reverse and zipper technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of not having, chain teeth separated, etc., to achieve significant effects, avoid collisions, and increase the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

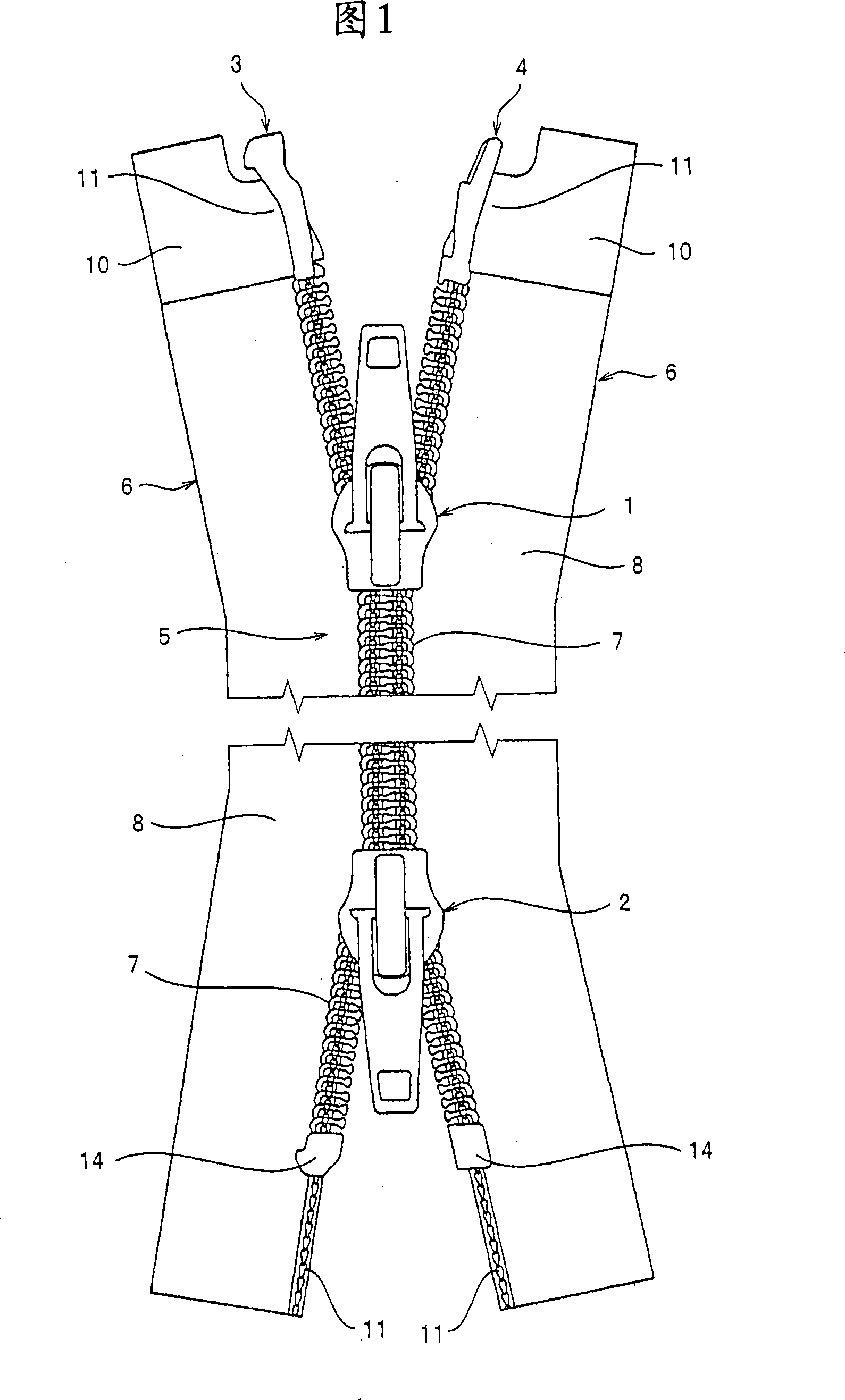

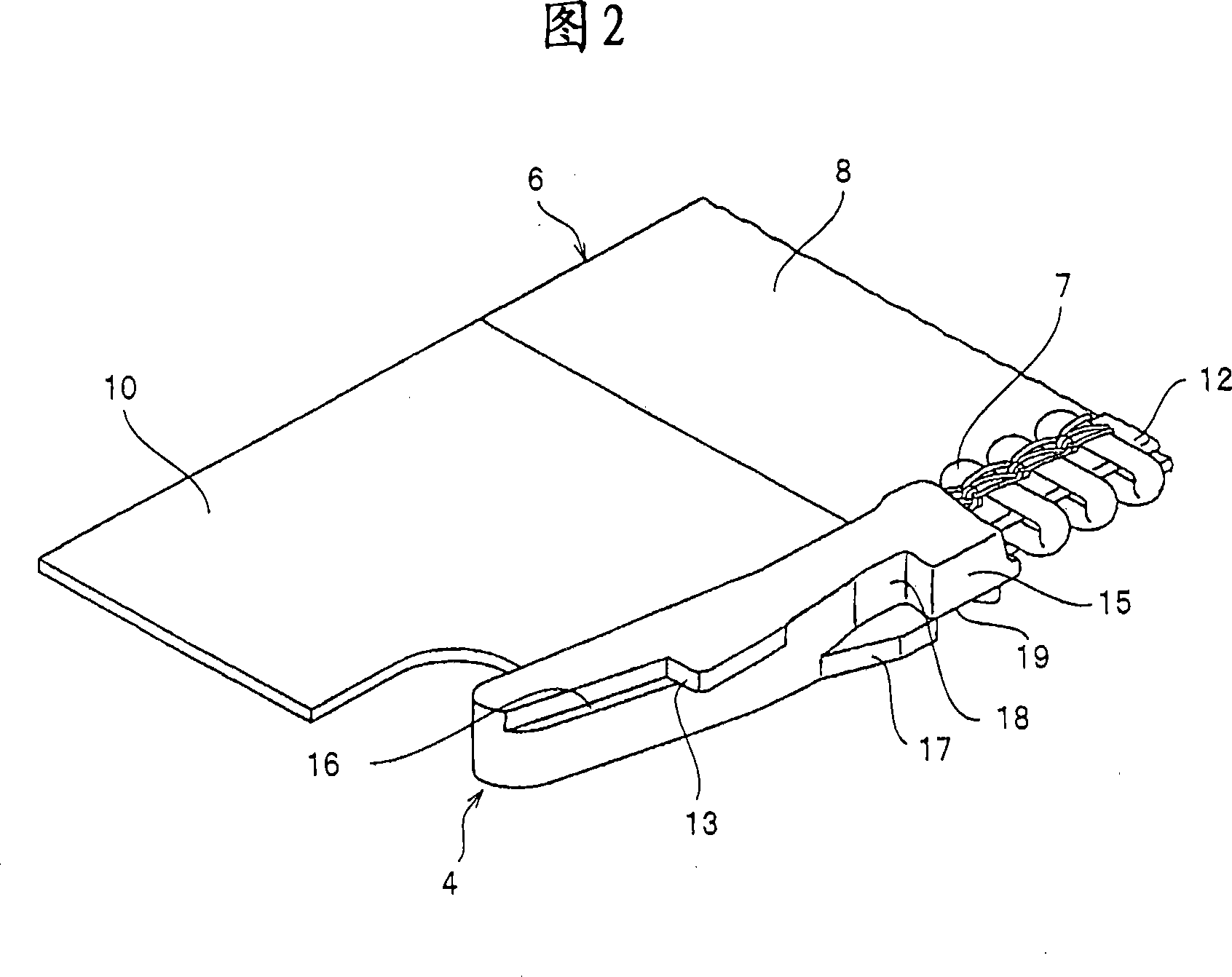

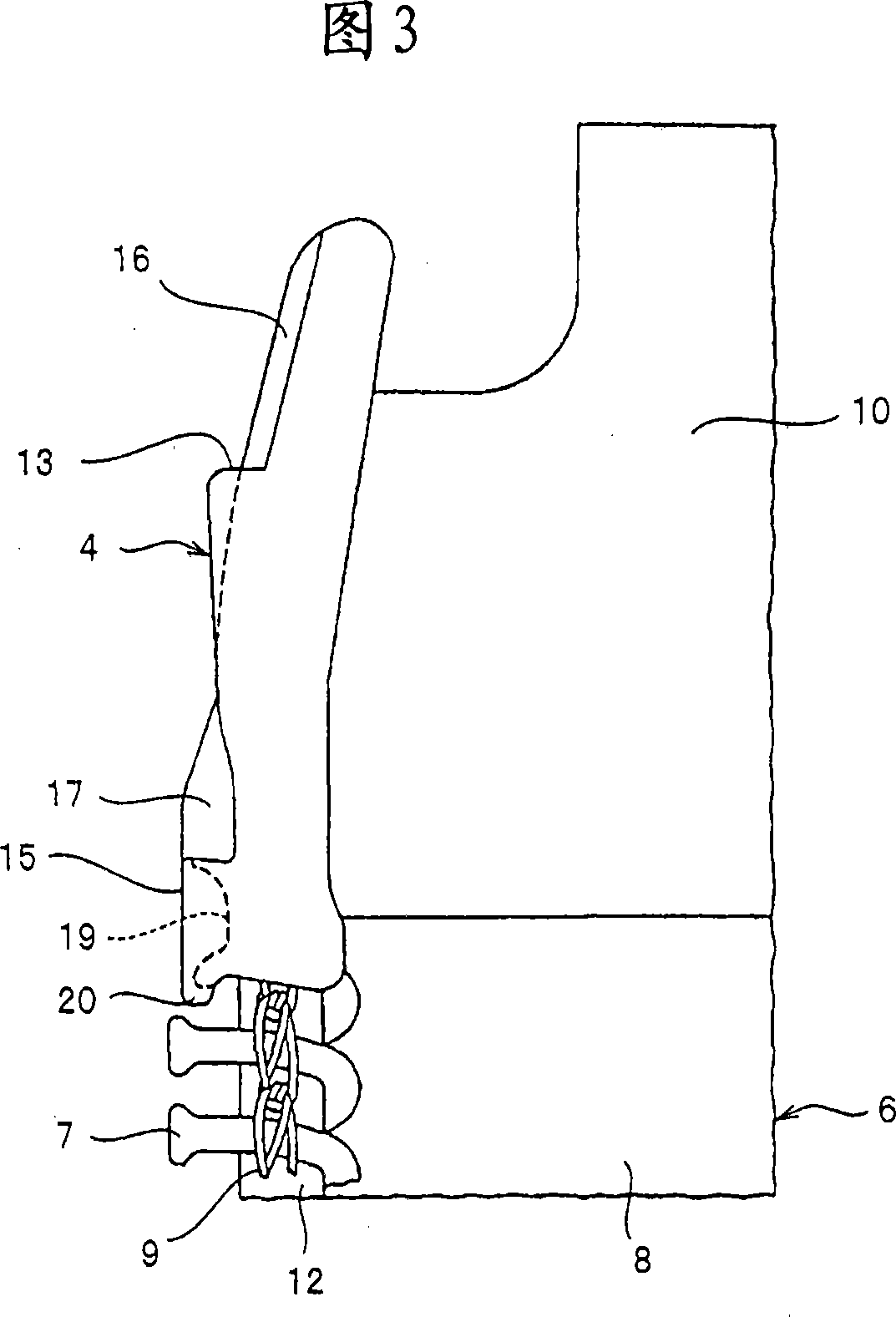

[0049] According to the first embodiment of the reverse opening detachable end stop of the zipper shown in FIGS. Mobile body. The tooth chain 5 is manufactured by winding a synthetic resin monofilament such as polyamide, polyester, etc. into a roll or bending it into a zigzag shape to form linear fastener elements 7 continuous in the longitudinal direction of the fastener tape 8, and then wrapping the core The thread 12 passes through the inside of the fastener element 7, and utilizes the sewing thread 9 to sew it along the longitudinal edge of the fastener tape 8 along one side. Alternatively, by injection molding, thermoplastic resins such as polyacetal, polyamide, polypropylene, and polybutylene terephthalate may be used at predetermined intervals along the longitudinal direction of the fastener tape 8 . A single group of fastener teeth is formed on the expansion part formed by one side edge of the longitudinal direction of 8, so as to form tooth chain 5.

[0050] A free ...

no. 2 example

[0069] According to the second embodiment shown in Figures 13 and 14, the reverse-opening detachable end stop of the zipper is characterized in that the seat tube 3 has a function for limiting the reverse-opening slider 1 to the inner side of the tooth chain 5 Mobile body. The structure of the tooth chain 5 is the same as that in the first embodiment. In the fastener chain 5, utilize the sewing thread 9 to sew the coiled fastener element 7 containing the core thread 12 along the longitudinal side edges of the fastener tapes 8, 8 of a pair of left and right single side fastener chains 6, 6. The reinforcing part 10 is formed by bonding a resin film to a vacant part 11 disposed at one end of each one-sided fastener chain 6, 6 in the longitudinal direction, and the seat tube 3 is made of a thermoplastic resin film on the reinforcing part 10 of the one-sided fastener chain 6. Formed, and the insertion tube 4 is formed by thermoplastic resin on the reinforcement part 10 of the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com