Tester for testing the performance of new material degrading tail gas

A technology for degrading exhaust gas and test equipment, which is applied to measurement equipment, analytical materials, instruments, etc., can solve the problems of large temperature and environmental changes in test results, opaque gas reaction chamber, limited use range, etc., to avoid testing Inaccurate results, economical, and unrestricted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

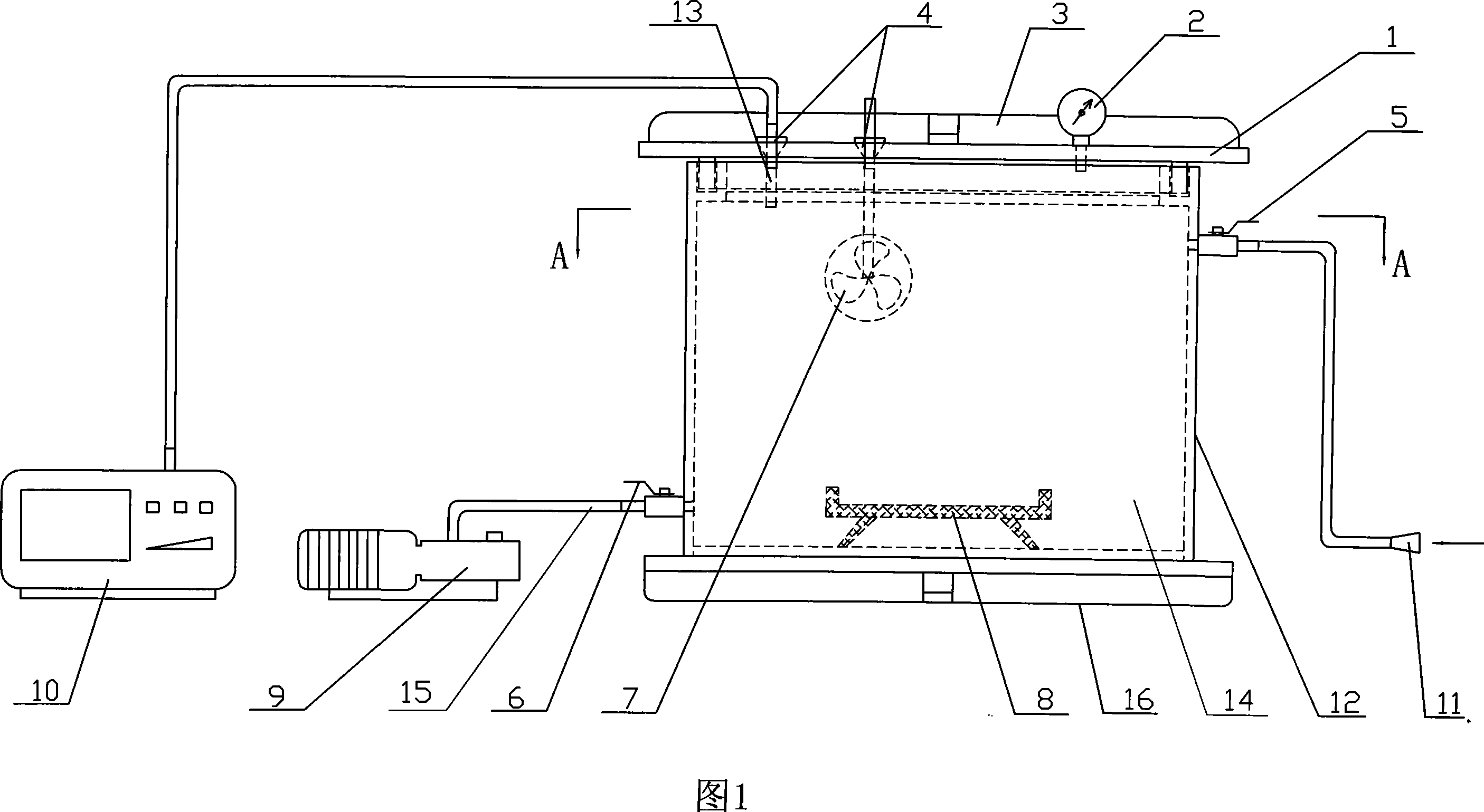

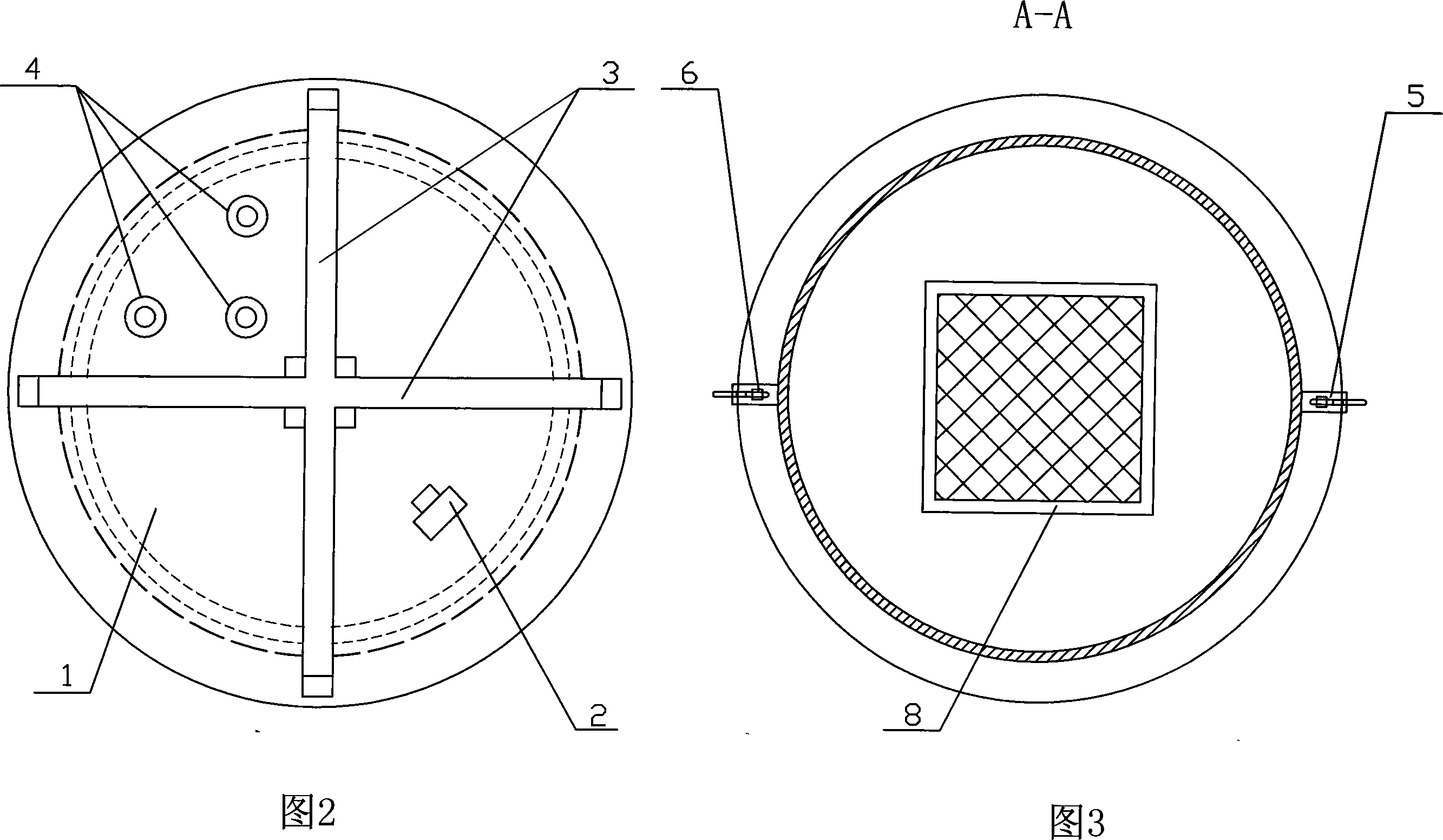

[0007] Embodiment 1: As shown in Figures 1 to 3, the test device for testing the degradation tail gas performance of new materials in this embodiment consists of a gas reaction chamber 12, an exhaust gas analyzer 10, a sensor probe 13, a vacuum pump 9, a fan 7, a negative Pressure gauge 2, intake valve 5, pumping / exhaust valve 6, connecting pipe 15, intake pipe 11 are made up; Described gas reaction chamber 12 is to be made of translucent material, and gas reaction chamber 12 is made of sealing cover 1 and reaction chamber container 14, the sealing cover 1 is airtightly connected with the reaction chamber container 14, the sensor probe 13 is plugged into the socket 4 on the sealing cover 1 and connected with the exhaust gas analyzer 10, the vacuum pump 9 and the bottom end of the reaction chamber container 14 pass through Connecting pipe 15 communicates, and described connecting pipe 15 is provided with suction / exhaust valve 6, and inlet pipe 11 is communicated with the upper e...

specific Embodiment approach 2

[0009] Embodiment 2: The gas reaction chamber 12 in this embodiment is made of organic glass material. The advantages of plexiglass are good light transmission, strong sealing, and easy observation, and can directly use natural light sources for experiments, which is closer to the actual environment, and also reduces the temperature impact caused by the use of ultraviolet light sources. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: As shown in Fig. 1 and Fig. 2 , the seal cap 1 in this embodiment is provided with a seal cap cross-shaped stiffening beam 3 . It is designed in this way to strengthen its anti-deformation performance and ensure the vacuum working ability of the gas chamber. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com