Antistatic wheel tyre

An anti-static and tire technology, applied to tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of unstable effect, great influence on conductive characteristics, limited effect, etc., achieve continuous poor contact, and completely discharge static electricity , The effect of eliminating the charge difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

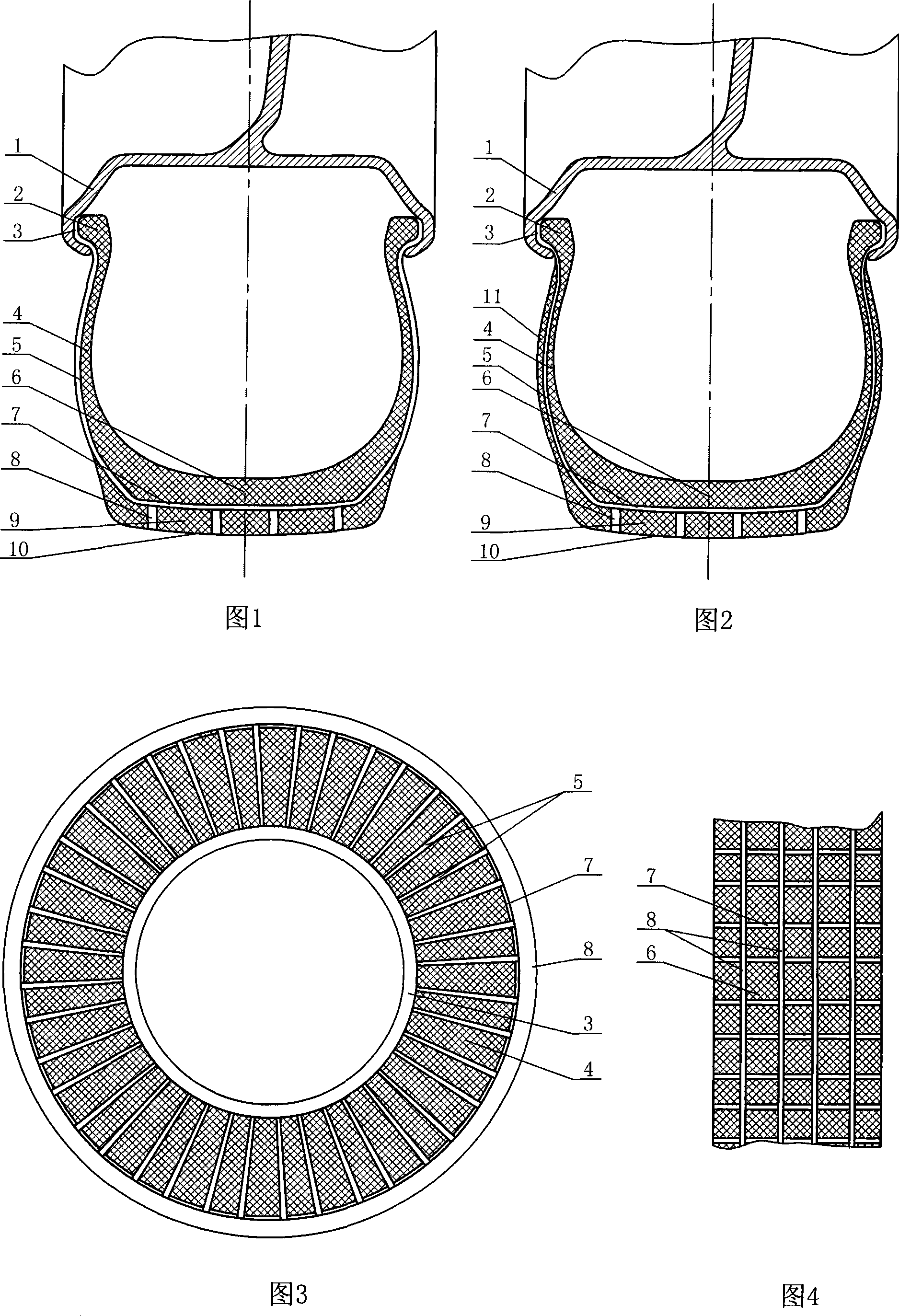

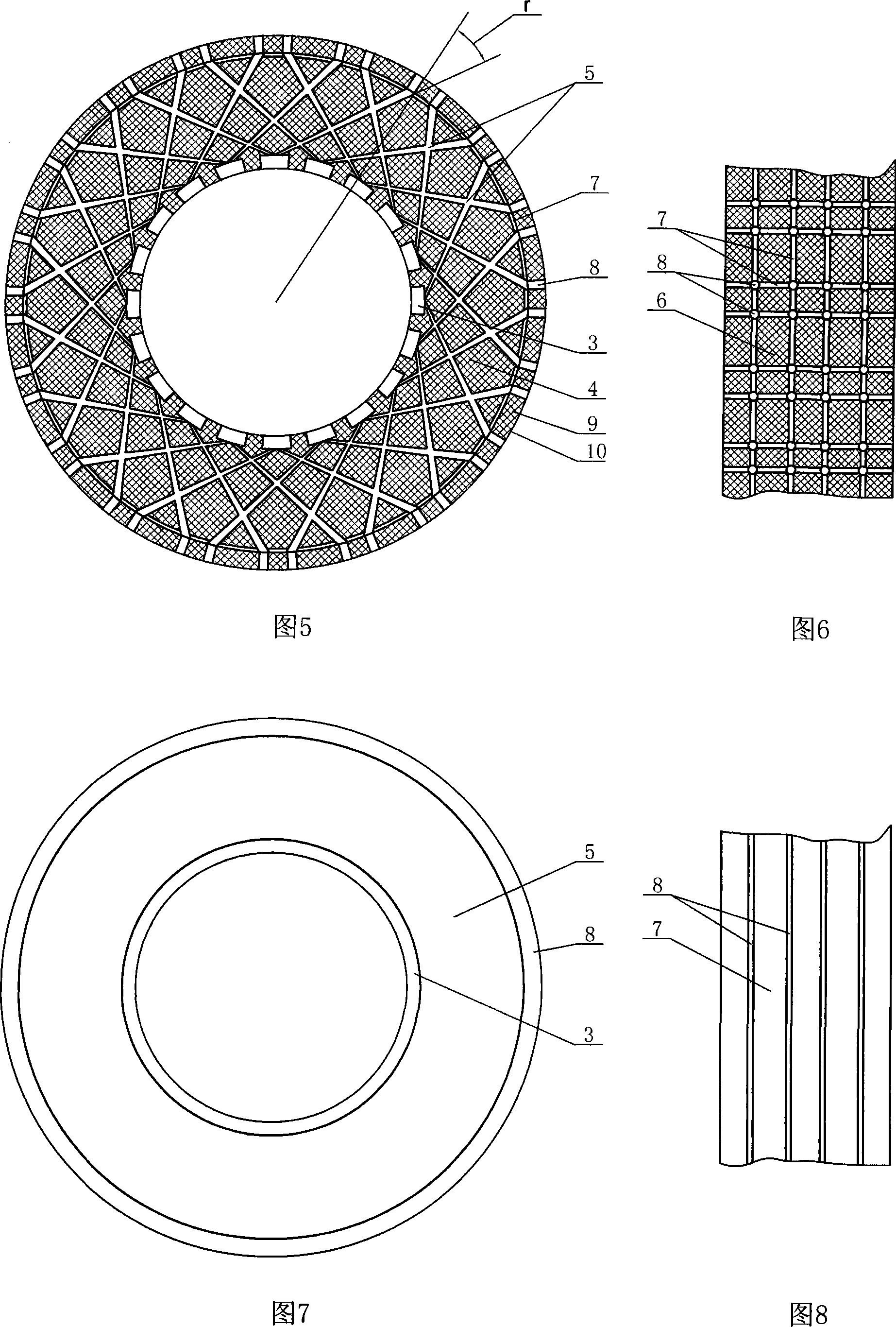

[0025] Referring to FIG. 1 , the antistatic tire of the present invention includes a conductive layer that electrically connects the rim 1 with the ground contact surface 10 of the tire. The conductive layer is mainly divided into three parts: the conductive layer 3 of the bead 2 part, the conductive layer 5 of the sidewall 4 part, and the conductive layer 7 of the tire crown 6 part. The bead conductive layer 3 is arranged on the outer surface of the bead 2 and can be in direct contact with a part of the surface of the rim 1 after being assembled with the rim 1 . Its function is to realize the electrical connection between the conductive layer and the rim 1 . The sidewall conductive layer 5 is located on the outer surface of the sidewall 4 , and its function is equivalent to a wire, transferring the electrostatic charge received by the bead conductive layer 3 to the crown conductive layer 7 . In this embodiment, the sidewall conductive layer 5 is arranged on the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com